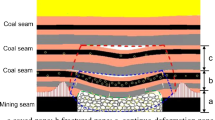

China is rich in primary energy resources. Due to specific terrain conditions, different types of problems may occur in the process of development. When the coal seams are located under the oil layers, due to the physical characteristics of oil, the exploitation of coal seams will cause losses to the oil layers, and the volatile oil may also cause threats to coal mining. To analyze the fracture development and leakage characteristics of overburden strata for this type of geological conditions, we have carried out physical simulation experiments and performed a further numerical simulation to study and verify the evolution of fractures. Based on numerical simulation results, methods have been proposed that may effectively reduce the air leakage in the working face and control the parameters, including viscous resistance, distance, and the construction period of the blocking. In this paper, based on the 30100 face in the Nanliang coal mine as an example, we have proved that the proposed measures can provide good theoretical guidance for the prevention of spontaneous combustion of residual coal and control of water in coal mine production. The developed method offers good economic benefits for safe production in coal mines.

Similar content being viewed by others

References

M. F. Cai, Rock Mechanics and Engineering, Science Press, Beijing (2002), pp. 145-189.

G. S. Zhang, Ventilation Safety, China University of Mining and Technology Press, Beijing (2000), pp. 202–246.

Q. X. Huang and M. G. Qian, “Structural analysis of periodic weighting of old roof in shallow coal seam,” J. Coal Ind., 24(06), 581-585 (1999).

Z. J. Hou, “Analysis of combinatorial key strata stability in shallow coal seam with thick loose bed,” J. Coal Ind., 25(02), 15-19 (2000).

X. H. Zhang, G. Wu, Y. F. Jin, et al., “Research on numerical simulation of air leakage and risk of spontaneous combustion under the condition of strong leakage and shallow coal seams,” Value Eng., 30(021), 1-3 (2011).

F. X. Jiang, S. T. Zhu, J. H. Liu, et al., “Control of abnormal weighing in fully mechanized/caving face of deep shaft,” J. Rock Mech. Eng., 32(8), 1528-1536 (2013).

D. S. Zhang, G. W. Fan, and S. Zhang, “Overburden strata movement law of fully top coal caving mining face under ultra-thick alluvium and thin base rock,” J. Coal Eng., 46(10), 146-148 (2014).

T. X. Chu, M. G. Yu, S. Q. Yang, et al., “Air leaking induced by well-developed coal fractures and prevention of spontaneous combustion in goaf,” J. Min. Safety Eng., 27(1), 91-97 (2010).

Y. X. Ren and H. X. Chen, Fundamentals of Computational Fluid Dynamics, Tsinghua University Press, Beijing (2006).

S. Q. Yang, Q. Xu, J. Jin, et al., “The “three zones” microcirculation theory of goaf spontaneous combustion and a numerical simulation of the air leakage flow field,” J. Chin. Univ. Min. Technol., 38(6), 769-773 (2009).

F. C. Zhang, “Air leakage measurement technology with SF6 tracer gas applied to Shendong mining area,” J. Coal Eng., 06, 94-96 (2006).

S. X. Li, B. Lu, and T. X. Chu, “Air leakage characteristics and the stoppage practice in shallow buried working face,” J. Coal Eng., 49(10), 91-93 (2017).

J. W. Cai, S.Q. Yang, and H. L. Jiao, Experimental study on gob three-dimensional flow field of “U+L” ventilation system,” J. Coal Eng., 48(8), 89-92 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 3, pp. 89–93, May–June, 2021.

Rights and permissions

About this article

Cite this article

Zhang, J., Bai, W., Zhang, J. et al. Investigation of Fracture Development and Oilfield Protection in the Extraction of Carbon Materials. Chem Technol Fuels Oils 57, 552–560 (2021). https://doi.org/10.1007/s10553-021-01277-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-021-01277-0