Abstract

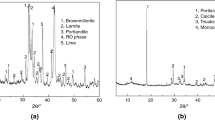

To utilize the steel slag (SS) on a large scale and sequester CO2, a room-temperature wet carbonation process with the assistance of ethylene-diamine-tetra-acetic acid (EDTA) was developed. In this work, the accelerated carbonation process of SS with EDTA was investigated. The evolution of phase composition and microstructure of carbonated steel slag (CSS) was revealed by XRD, TG/DTG, FT-IR and SEM. The results show that the carbonation reaction can reduce the content of free calcium oxide in SS, and the volume stability of CSS-cement cementitious materials is greatly improved. The carbonation products are mainly fine calcite and the 28-day compressive strength of cementitious materials containing CSS is improved. EDTA accelerates the calcium leaching and has a catalytic effect on the carbonation reaction through chelating effect. SS with EDTA reached a CO2 sequestration rate of 14.3% after 60 min of carbonation. In addition, the cyclic performance of the continuous wet carbonation process was investigated. Although the CO2 sequestration efficiency of each cycle dropped, they were still higher than that of the control group, indicating the good potential for the continuous wet carbonation method through solvent recovery.

Similar content being viewed by others

Data availability statement

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Huang X, Wu H, Lu D (2021) Preparation of novel chemically bonded ceramics with steel slag and potassium hydrogen oxalate. J Hazard Mater 403:124042. https://doi.org/10.1016/j.jhazmat.2020.124042

WS, 2022. World steel in figures 2022 now available. Brussels, Belgium. https://worldsteel.org/media-centre/press-releases/2022/world-steel-in-figures-2022-now-available/

Huang Y, Xu G, Cheng H, Wang J, Wan Y, Hui C (2012) An Overview of utilization of steel slag. Procedia Environ Sci 16:791–801. https://doi.org/10.1016/j.proenv.2012.10.108

Zhao J, Yan P, Wang D (2017) Research on mineral characteristics of converter steel slag and its comprehensive utilization of internal and external recycle. J Clean Prod 156:50–61. https://doi.org/10.1016/j.jclepro.2017.04.029

Chen Z, Li R, Zheng X, Liu J (2021) Carbon sequestration of steel slag and carbonation for activating RO phase. Cement Concr. Res. 139:106271. https://doi.org/10.1016/j.cemconres.2020.106271

Wang JF, Chang L, Yue DY, Zhou YF, Liu H, Wang YL, Yang SG, Cui SP (2022) Effect of chelating solubilization via different alkanolamines on the dissolution properties of steel slag. J Clean Prod 365:132824. https://doi.org/10.1016/j.jclepro.2022.132824

Juenger MCG, Snellings R, Bernal SA (2019) Supplementary cementitious materials: new sources, characterization, and performance insights. Cement Concr Res 122:257–273. https://doi.org/10.1016/j.cemconres.2019.05.008

Song Q, Guo M, Wang L, Ling T (2021) Use of steel slag as sustainable construction materials: a review of accelerated carbonation treatment. Resour Conserv Recycl 173:105740. https://doi.org/10.1016/j.resconrec.2021.105740

Mo L, Zhang F, Deng M (2016) Mechanical performance and microstructure of the calcium carbonate binders produced by carbonating steel slag paste under CO2 curing. Cement Concr Res 88:217–226. https://doi.org/10.1016/j.cemconres.2016.05.013

Wang D, Xiao J, Duan Z (2022) Strategies to accelerate CO2 sequestration of cement-based materials and their application prospects. Constr Build Mater 314:125646. https://doi.org/10.1016/j.conbuildmat.2021.125646

Why-Ling Tan AL, Ahmad CPL, Lam SS (2020) A critical review to bridge the gaps between carbon capture, storage and use of CaCO3. J CO2 Util 42:101333. https://doi.org/10.1016/j.jcou.2020.101333

Zajac M, Skibsted J, Skocek J, Durdzinski P, Bullerjahn F, Haha MB (2020) Phase assemblage and microstructure of cement paste subjected to enforced, wet carbonation. Cement Concr Res. 130:105990. https://doi.org/10.1016/j.cemconres.2020.105990

Zajac M, Skibsted J, Durdzinski P, Bullerjahn F, Skocek J, Haha MB (2020) Kinetics of enforced carbonation of cement paste. Cement Concr. Res. 131:106013. https://doi.org/10.1016/j.cemconres.2020.106013

Zajac M, Skocek J, Durdzinski P, Bullerjahn F, Skibsted J, Haha MB (2020) Cement concr. Res 134:106090. https://doi.org/10.1016/j.cemconres.2020.106090

Shen P, Zhang Y, Jiang Y, Zhan B, Lu J, Zhang S, Xuan D, Poon C (2022) Phase assemblance evolution during wet carbonation of recycled concrete fines. Cement Concr. Res. 154:106733. https://doi.org/10.1016/j.cemconres.2022.106733

Liu S, Shen Y, Wang Y, Shen P, Xuan D, Guan X, Shi C (2022) Upcycling sintering red mud waste for novel superfine composite mineral admixture and CO2 sequestration. Cem Concr Compos 129:104497. https://doi.org/10.1016/j.cemconcomp.2022.104497

Chen Z, Li R, Liu J (2021) Preparation and properties of carbonated steel slag used in cement cementitious materials. Constr Build Mater 283:122667. https://doi.org/10.1016/j.conbuildmat.2021.122667

Ma M, Mehdizadeh H, Guo M, Ling T (2021) Effect of direct carbonation routes of basic oxygen furnace slag (BOFS) on strength and hydration of blended cement paste. Constr Build Mater 304:124628. https://doi.org/10.1016/j.conbuildmat.2021.124628

Luo Y, He D (2021) Research status and future challenge for CO2 sequestration by mineral carbonation strategy using iron and steel slag. Environ Sci Pollut Res 28:49383–49409. https://doi.org/10.1007/s11356-021-15254-x

Zheng X, Liu J, Wei Y, Li K, Yu H, Wang X, Ji L, Yan S (2022) Glycine-mediated leaching-mineralization cycle for CO2 sequestration and CaCO3 production from coal fly ash: dual functions of glycine as a proton donor and receptor. Chem Eng J 440:135990. https://doi.org/10.1016/j.cej.2022.135900

Kim M-J, Jeon J (2020) Effects of Ca-ligand stability constant and chelating agent concentration on the CO2 storage using paper sludge ash and chelating agent. J CO2 Util 40:101202. https://doi.org/10.1016/j.jcou.2020.101202

Liendo F, Arduino M, Deorsola FA, Bensaid S (2021) Factors controlling and influencing polymorphism, morphology and size of calcium carbonate synthesized through the carbonation route: a review. Powder Technol 22:117050. https://doi.org/10.1016/j.powtec.2021.117050

Xiang L, Xiang Y, Wang ZG, Jin Y (2002) Influence of chemical additives on the formation of super-fine calcium carbonate. Powder Technol 126:129–133. https://doi.org/10.1016/s0032-5910(02)00047-5

Zhao H, Park Y, Lee DH, Park A-HA (2013) Tuning the dissolution kinetics of wollastonite via chelating agents for CO2 sequestration with integrated synthesis of precipitated calcium carbonates. Phys Chem Chem Phys 15:15185. https://doi.org/10.1039/c3cp52459k

Yang S, Mo L, Deng M (2021) Effects of ethylenediamine tetra-acetic acid (EDTA) on the accelerated carbonation and properties of artificial steel slag aggregates. Cem Concr Compos 118:103948. https://doi.org/10.1016/j.cemconcomp.2021.103948

Martell AE (1952) The behavior of metal complexes in aqueous solutions. J Chem Educ 29(6):270. https://doi.org/10.1021/ed029p270

Huijgen WJJ, Witkamp G-J, Comans RNJ (2005) Mineral CO2 sequestration by steel slag carbonation. Environ Sci Technol 39:9676–9682. https://doi.org/10.1021/es050795f

Gomez-Villalba LS, Lopez-Arce P, Alvarez de Buergo M, Fort R (2012) Atomic defects and their relationship to aragonite–calcite transformation in portlandite manocrystal carbonation. Cryst Growth Des 12(10):4844–4852. https://doi.org/10.1021/cg300628m

Gopi SP, Subramanian VK (2012) Polymorphism in CaCO3 — effect of temperature under the influence of EDTA (di sodium salt). Desalination 297:38–47. https://doi.org/10.1016/j.desal.2012.04.015

Mollah MYA, Yu W, Schennach R, Cocke DL (2000) A Fourier transform infrared spectroscopic investigation of the early hydration of Portland cement and the influence of sodium lignosulfonate. Cem Concr Res 30(2):267–273. https://doi.org/10.1016/s0008-8846(99)00243-4

Wang Q, Wang D, Zhuang S (2017) The soundness of steel slag with different free CaO and MgO contents. Constr Build Mater 151:138–146. https://doi.org/10.1016/j.conbuildmat.2017.06.077

Pan SY, Huang CH, Chan YW, Kim H, Li P, Chiang PC (2016) Integrated CO2 fixation, waste stabilization, and product utilization via high-gravity carbonation process exemplified by circular fluidizes bed fly ash. ACS Sustain Chem Eng 4:3045–3052. https://doi.org/10.1021/acssuschemeng.6b00014

Liu Q, Liu J, Qi L (2016) Effects of temperature and carbonation curing on the mechanical properties of steel slag-cement binding materials. Constr Build Mater 124:999–1006. https://doi.org/10.1016/j.conbuildmat.2016.08.131

Wang X, Ni W, Li AJ, Pascual R (2019) Carbonation of steel slag and gypsum for building materials and associated reaction mechanisms. Cem Concr Res 125:105893. https://doi.org/10.1016/j.cemconres.2019.105893

Rui Y, Qian C, Zhang X, Ma Z (2022) Different carbon treatments for steel slag powder and their subsequent effects on properties of cement-based materials. J Clean Prod 362:132407. https://doi.org/10.1016/j.jclepro.2022.132407

Liu G, Tang Y, Wang J (2023) Effects of carbonation degree of semi-dry carbonated converter steel slag on the performance of blended cement mortar–reactivity, hydration, and strength. J Build Eng. 63:105529. https://doi.org/10.1016/j.jobe.2022.105529

Zhang Y, Gao L, Cai X, Li Q, Kong X (2020) Influences of triethanolamine on the performance of cement pastes used in slab track. Constr Build Mater 238:117670. https://doi.org/10.1016/j.conbuildmat.2019.117670

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51874013, 52074019).

Funding

National Natural Science Foundation of China, 51874013, Jiaxiang Liu, 52074019, Jiaxiang Liu.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, T., Xue, Y., Zhao, X. et al. Effects of EDTA on the accelerated carbonation behavior of steel slag used as cementitious materials. J Mater Cycles Waste Manag 25, 1498–1508 (2023). https://doi.org/10.1007/s10163-023-01622-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-023-01622-x