Abstract

The use of renewable materials and cleaner production is currently the target of the automotive industry to reduce the use-phase environmental impacts of vehicles. Renewable lightweight materials are used to replace conventional materials to produce lightweight automotive parts, leading to reduced fuel consumption, which contributes toward meeting the industry’s environmental impact target. In this study, we compared the life cycle of a conventional composite to that of a biocomposite for automotive applications using the standard set by the International Standards Organization (ISO 2006). The conventional one is talc-reinforced polypropylene composite (talc–PP) at a 70% PP to 30% talc weight ratio. The biocomposite is Miscanthus biochar-reinforced polypropylene composite (MB–PP) at a 70% PP to 30% MB. The functional unit is 982 cm3 of composite used for a certain vehicle part (i.e., an automotive component). The environmental impacts are determined using the Tool for the Reduction and Assessment of Chemical and Other Environmental Impacts (TRACI, v2.1). The system boundary includes material extraction to the disposal stage of the composites. The results revealed that MB–PP composite had the least impact for all categories than talc–PP composite and appeared to be a favorable option for automotive parts from an environmental perspective. This study indicates that MB-PP can reduce about 25% environmental impacts of the life of composite if it replaces the talc–PP composite. The MB–PP composite emerged as a promising option than talc–PP composite and has environmentally benign green credentials for automotive parts application.

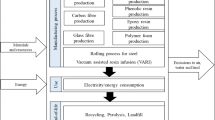

Graphic abstract

Similar content being viewed by others

References

Akhshik M, Panthapulakkal S, Tjong J, Sain M (2017) Life cycle assessment and cost analysis of hybrid fiber-reinforced engine beauty cover in comparison with glass fiber-reinforced counterpart. Environ Impact Assess Rev 65:111–117

Arrigoni A, Pelosato R, Melia P et al (2017) Life cycle assessment of natural building materials: the role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. J Clean Prod 149:1051–1061

Badino V, Baldo GL, Fornaro M, Salvaia E (1995) Ecobalance of talc mineral production. III International Congress “Energy Evironmenta and Technological Innovation”, II. 125–131

Bare J (2011) TRACI 2.o: the tool for the reduction and assessment of chemical and other environmental impacts 2.o. Clean Technol Environ Policy 13:687–696. https://doi.org/10.1007/s10098-010-0338-9

Barth M, Carus M (2015) Carbon footprint and sustainability of different natural fibres for biocomposites and insulation material. Hürth Nova-Institute Available online http//eiha org/media/2017/01/15-04-Carbon-Footprint-of-Natural-Fibres-nova1 pdf. Accessed 5 Sept 2017

Bartocci P, Bidini G, Saputo P, Fantozzi F (2016) Biochar pellet carbon footprint. Chem Eng 50:217–222

Behazin E, Misra M, Mohanty AK (2017) Sustainable biocarbon from pyrolyzed perennial grasses and their effects on impact modified polypropylene biocomposites. Compos Part B Eng 118:116–124. https://doi.org/10.1016/j.compositesb.2017.03.003

Beigbeder J, Soccalingame L, Perrin D et al (2019) How to manage biocomposites wastes end of life? A life cycle assessment approach (LCA) focused on polypropylene (PP)/wood flour and polylactic acid (PLA)/flax fibres biocomposites. Waste Manag 83:184–193

Boland C, Dekleine R, Moorthy A et al (2014) A life cycle assessment of natural fiber reinforced composites in automotive applications. SAE Tech Pap. https://doi.org/10.4271/2014-01-1959

Boland CS, De Kleine R, Keoleian GA et al (2016) Life cycle impacts of natural fiber composites for automotive applications: effects of renewable energy content and lightweighting. J Ind Ecol 20:179–189. https://doi.org/10.1111/jiec.12286

Brassard P, Godbout S, Pelletier F et al (2018) Pyrolysis of switchgrass in an auger reactor for biochar production: a greenhouse gas and energy impacts assessment. Biomass Bioenerg 116:99–105

Civancik-Uslu D, Ferrer L, Puig R, Fullana-i-Palmer P (2018) Are functional fillers improving environmental behavior of plastics? A review on LCA studies. Sci Total Environ 626:927–940. https://doi.org/10.1016/j.scitotenv.2018.01.149

Corbière-Nicollier T, Gfeller Laban B, Lundquist L et al (2001) Life cycle assessment of biofibres replacing glass fibres as reinforcement in plastics. Resour Conserv Recycl 33:267–287. https://doi.org/10.1016/S0921-3449(01)00089-1

Delogu M, Zanchi L, Dattilo CA, Pierini M (2017) Innovative composites and hybrid materials for electric vehicles lightweight design in a sustainability perspective. Mater Today Commun 13:192–209. https://doi.org/10.1016/j.mtcomm.2017.09.012

Delogu M, Zanchi L, Maltese S et al (2016) Environmental and economic life cycle assessment of a lightweight solution for an automotive component: a comparison between talc-filled and hollow glass microspheres-reinforced polymer composites. J Clean Prod 139:548–560. https://doi.org/10.1016/j.jclepro.2016.08.079

Europe P (2005) Eco-profiles of the European plastics industry. Low Density Polyethylene, pp 1–19

Fogorasi M, Barbu I (2017) The potential of natural fibres for automotive sector: review. IOP Conf Ser Mater Sci Eng 252:012044. https://doi.org/10.1088/1757-899X/252/1/012044

Giroux L, Consulting GE (2014) State of waste management in Canada. Canadian Council of Ministers of the Environment

Government of Canadan (2018) Environment and Climate Change Canada (2018) Canadian environmental sustainability indicators: greenhouse gas emissions

Greenblatt JB, Shaheen S (2015) Automated vehicles, on-demand mobility, and environmental impacts. Curr Sustain Energy Rep 2:74–81

Guinée JB, Heijungs R, Huppes G (2004) Economic allocation: examples and derived decision tree. Int J Life Cycle Assess 9:23

Han J, Elgowainy A, Dunn JB, Wang MQ (2013) Life cycle analysis of fuel production from fast pyrolysis of biomass. Bioresour Technol 133:421–428

Han J, Elgowainy A, Palou-Rivera I, et al (2011) Well-to-wheels analysis of fast pyrolysis pathways with the GREET model. Argonne National Lab.(ANL), Argonne, IL (United States)

Hervy M, Evangelisti S, Lettieri P, Lee K-Y (2015) Life cycle assessment of nanocellulose-reinforced advanced fibre composites. Compos Sci Technol 118:154–162. https://doi.org/10.1016/J.COMPSCITECH.2015.08.024

ISO (2006) Environmental management—Life cycle assessment—Requirements and guidelines

Jahirul MI, Rasul MG, Chowdhury AA, Ashwath N (2012) Biofuels production through biomass pyrolysis—a technological review. Energies 5:4952–5001. https://doi.org/10.3390/en5124952

Jan MR, Shah J, Gulab H (2013) Catalytic conversion of waste high-density polyethylene into useful hydrocarbons. Fuel 105:595–602. https://doi.org/10.1016/j.fuel.2012.09.016

Jungbluth N, Bauer C, Dones R, Frischknecht R (2005) Life cycle assessment for emerging technologies: case studies for photovoltaic and wind power (11 pp). Int J Life Cycle Assess 10:24–34

Kim HC, Wallington TJ (2013) Life-cycle energy and greenhouse gas emission benefits of lightweighting in automobiles: review and harmonization. Environ Sci Technol 47:6089–6097. https://doi.org/10.1021/es3042115

Kong S (2011) (12) United States Patent 2, pp 12–15

Leme MMV, Rocha MH, Lora EES et al (2014) Techno-economic analysis and environmental impact assessment of energy recovery from Municipal Solid Waste (MSW) in Brazil. Resour Conserv Recycl 87:8–20

Luz SM, Caldeira-Pires A, Ferrão PMC (2010) Environmental benefits of substituting talc by sugarcane bagasse fibers as reinforcement in polypropylene composites: ecodesign and LCA as strategy for automotive components. Resour Conserv Recycl 54:1135–1144. https://doi.org/10.1016/j.resconrec.2010.03.009

Mashouf Roudsari G, Mohanty AK, Misra M (2017) A statistical approach to develop biocomposites from epoxy resin, poly(furfuryl alcohol), poly(propylene carbonate), and biochar. J Appl Polym Sci 134:1–11. https://doi.org/10.1002/app.45307

Molins G, Álvarez MD, Garrido N et al (2018) Environmental impact assessment of polylactide (PLA)/chicken feathers biocomposite materials. J Polym Environ 26:873–884

Moussa H (2014) Life cycle assessment of a hybrid poly butylene succinate composite

Narayan R (2011) Carbon footprint of bioplastics using biocarbon content analysis and life-cycle assessment. MRS Bull 36:716–721. https://doi.org/10.1557/mrs.2011.210

Neufeld R, Massicotte PJ (2017) Decarbonizing transportation in Canada

Peters JF, Iribarren D, Dufour J (2015) Simulation and life cycle assessment of biofuel production via fast pyrolysis and hydroupgrading. Fuel 139:441–456

Poulikidou S, Schneider C, Björklund A et al (2015) A material selection approach to evaluate material substitution for minimizing the life cycle environmental impact of vehicles. Mater Des 83:704–712. https://doi.org/10.1016/j.matdes.2015.06.079

Roy P, Nei D, Okadome H et al (2008) Life cycle inventory analysis of fresh tomato distribution systems in Japan considering the quality aspect. J Food Eng 86:225–233. https://doi.org/10.1016/j.jfoodeng.2007.09.033

Roy P, Tadele D, Defersha F et al (2019) Environmental and economic prospects of biomaterials in the automotive industry. Clean Technol Environ Policy 21(8):1535–1548

Snowdon MR, Mohanty AK, Misra M (2017) Miscibility and Performance Evaluation of Biocomposites Made from Polypropylene/Poly(lactic acid)/Poly(hydroxybutyrate-cohydroxyvalerate) with a Sustainable Biocarbon Filler. ACS Omega 2:6446–6454. https://doi.org/10.1021/acsomega.7b00983

Subic A, Schiavone F, Leary M, Manning J (2010) Comparative Life Cycle Assessment (LCA) of passenger seats and their impact on different vehicle models. Int J Veh Des 53:89–109

Tadele D, Roy P, Defersha F et al (2019) Life Cycle Assessment of renewable filler material (biochar) produced from perennial grass (Miscanthus). AIMS Energy 7:430–440. https://doi.org/10.3934/energy.2019.4.430

Vidal R, Martínez P, Garraín D (2009) Life cycle assessment of composite materials made of recycled thermoplastics combined with rice husks and cotton linters. Int J Life Cycle Assess 14:73–82. https://doi.org/10.1007/s11367-008-0043-7

Väisänen T, Das O, Tomppo L (2017) A review on new bio-based constituents for natural fiber-polymer composites. J Clean Prod 149:582–596. https://doi.org/10.1016/j.jclepro.2017.02.132

Wang T, Rodriguez-Uribe A, Misra M, Mohanty AK (2018) Sustainable carbonaceous biofiller from miscanthus: size reduction, characterization, and potential bio-composites applications. BioResources 13:3720–3739. https://doi.org/10.15376/biores.13.2.3720-3739

Wang H, Wang L, Shahbazi A (2015) Life cycle assessment of fast pyrolysis of municipal solid waste in North Carolina of USA. J Clean Prod 87:511–519

Witik RA, Payet J, Michaud V et al (2011) Assessing the life cycle costs and environmental performance of lightweight materials in automobile applications. Compos Part A Appl Sci Manuf 42:1694–1709. https://doi.org/10.1016/j.compositesa.2011.07.024

Wright MM, Daugaard DE, Satrio JA, Brown RC (2010) Techno-economic analysis of biomass fast pyrolysis to transportation fuels. Fuel 89:S2–S10

Acknowledgements

The authors would like to acknowledge financial support from the Ontario Research Fund–Research Excellence (ORF-RE) round-7 award and the growth fund from the School of Engineering, University of Guelph.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Tadele, D., Roy, P., Defersha, F. et al. A comparative life-cycle assessment of talc- and biochar-reinforced composites for lightweight automotive parts. Clean Techn Environ Policy 22, 639–649 (2020). https://doi.org/10.1007/s10098-019-01807-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-019-01807-9