Abstract

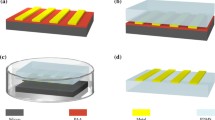

In this work we present a novel technology for tailoring the edges of a polymer sacrificial layer by combining multiple techniques. Standard polymers like Shipley Microposit S1818 for the sacrificial layers and gold as a structural layer have been used for our purposes. As a result, oblique profiles of double clamped bridges have been obtained, characterized by an improved homogeneity of the deposited metal thickness on the edges and by a very good surface planarity.

Similar content being viewed by others

References

Bartolucci G, Catoni S, Giacomozzi F, Marcelli R, Margesin B, Pochesci D (2007) Realisation of distributed RF MEMS phase shifter with very low number of switches. Electron Lett 43:1290–1292. doi:10.1049/el:20071679

Bartolucci G, De Angelis G, Lucibello A, Marcelli R, Proietti E (2012) Analytic modeling of RF MEMS shunt connected capacitive switches. J Electromagn Waves Appl 26:1168–1179. doi:10.1080/09205071.2012.710564

Bo L, Zhiqiu L, Zhihong L, Xunjun H, Yilong H (2010) A surface micromachining process utilizing dual metal sacrificial layer for fabrication of RF MEMS switch. In: Proceedings 5th IEEE international conference on nano/micro engineered and molecular systems. Xiamen, China, pp 620–623. doi:10.1109/NEMS.2010.5592479

Bühler J, Steiner FP, Baltes H (1997) Silicon dioxide sacrificial layer etching in surface micromachining. J Micromech Microeng 7:R1. doi:10.1088/0960-1317/7/1/001

Bustillo JM, Howe RT, Muller RS (1998) Surface micromachining for microelectromechanical systems. Proc IEEE 86:1552–1574. doi:10.1109/5.704260

Chung C, Allen M (2005) Uncrosslinked SU-8 as a sacrificial material. J Micromech Microeng 15:N1–N5. doi:10.1088/0960-1317/15/1/N01

Kovacs GTA, Maluf NI, Petersen KE (1998) Bulk micromachining of Silicon. Proc IEEE 86:1536–1551. doi:10.1109/5.704259

Levinson HJ (2005) The principles of lithography. SPIE Press, Bellingham, WA

Lindroos V, Tilli M, Lehto A, Motooka T (2010) Handbook of silicon based MEMS materials and technologies. Elsevier, Holland

Malek CK, Saile V (2004) Applications of LIGA technology to precision manufacturing of high-aspect-ratio micro components and systems: a review. Microelectron J 35:131–143. doi:10.1016/j.mejo.2003.10.003

Peroulis D, Margomenos A, Katehi LPB (2002) RF MEMS and Si micromachining in high frequency applications. In: Proceedings IEEE radio and wireless conference. Boston, pp 265–268. doi:10.1109/RAWCON.2002.1030168

Peroulis D, Pacheco SP, Sarabandi K, Katehi LPB (2003) Electromechanical considerations in developing low-voltage RF MEMS switches. IEEE Trans Microw Theory Tech 51:259–270. doi:10.1109/TMTT.2002.806514

Piyabongkarn D, Rajamani R, Greminger M (2005) The development of a MEMS gyroscope for absolute angle measurement. IEEE Trans Control Syst Technol 13:185–195. doi:10.1109/TCST.2004.839568

Rebeiz GM (2003) RF MEMS theory, design, and technology. Wiley, New Jersey

Schiltz A, Pons M (1985) Two layer planarization process. Microelectron Eng 3:507–509. doi:10.1016/0167-9317(85)90063-2

Van Zeijl HW, Nanver LK (2005) LPCVD silicon nitride-on-silicon spacer technology. In: Proceedings 20th international symposium on microelectronics technology and devices. Brazil, pp 153–162

Voskericiana G, Shive MS, Shawgo RS, Recum H, Anderson JM, Cima MJ, Langere R (2003) Biocompatibility and biofouling of MEMS drug delivery devices. Biomaterials 24:1959–1967. doi:10.1016/S0142-9612(02)00565-3

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lucibello, A., Proietti, E., Marcelli, R. et al. Smoothing and surface planarization of sacrificial layers in MEMS technology. Microsyst Technol 19, 845–851 (2013). https://doi.org/10.1007/s00542-013-1747-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-013-1747-6