Abstract

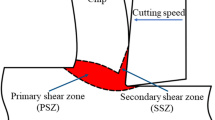

The Zerilli–Armstrong (ZA) model is modified to describe asymmetric visco-plastic material properties as part of a multi-mechanism model (MMM) for cutting simulations. This is done as an improvement of an existing modified Johnson–Cook (JC) model. Based on the modification of the ZA model by Samantatray et al. for elevated-temperature behaviour, we replace the hardening stress by the sum of nonlinear and linear isotropic hardening stresses using internal variables, thus consider history effects. Furthermore, weighting functions related to stress modes are applied taking asymmetric effect of strength into account. For calibrating the modified ZA model, experimental data in a wide range of strain rates and temperatures as well as under different loading types are used. Moreover, a systematic comparative study on the modified JC and ZA model is made regarding their dependence on strain, strain rate, and temperature. Finally, the modified ZA model is validated by comparing temperatures and cutting forces of cutting simulations with those of hard turning experiments.

Similar content being viewed by others

References

Abed, F.H., Voyiadjis, G.Z.: A consistent modified Zerilli–Armstrong flow stress model for BCC and FCC metals for elevated temperatures. Acta Mech. 175, 1–18 (2005)

Ammar, K., Appolaire, B., Cailletaud, G., Feyel, F., Forest, S.: Finite element formulation of a phase field model based on the concept of generalized stresses. Comput. Mater. Sci. 45, 800–805 (2009)

ASM Handbook: Mechanical Testing and Evaluation, Materials Part Ohio, Vol. 8 (2002)

Behrens, A., Westhoff, B., Kalisch, K.: Application of the finite element method at the chip forming process under high speed cutting conditions. In: Tönshoff, H.K., Hollmann, F. (Eds.) Hochgeschwindigkeitsspanen, pp. 112–134. Wiley (2005)

Carroll, J.T., Strenkowski, J.S.: Finite element models of orthogonal cutting with application to single point diamond turning. Int. J. Mech. Sci. 30, 899–920 (1988)

Chaboche, J.L.: A review of some plasticity and viscoplasticity constitutive theories. Int. J. Plast. 24, 1642–1693 (2008)

Chen, C., Yin, H., Humail, I.S., Wang, Y., Qu, X.: A comparative study of a back propagation artificial neural network and a Zerilli–Armstrong model for pure molybdenum during hot deformation. Int. J. Refract. Met. Hard Mater. 25(5–6), 411–416 (2007)

Cheng, C., Mahnken, R.: A multi-mechanism model for cutting simulations based on the concept of generalized stresses. Comput. Mater. Sci. B 100, 144–158 (2015)

Cheng, C., Mahnken, R.: Extension of a multi-mechanism model: hardness-based flow and transformation induced plasticity for austenitization. Int. J. Solids Struct. 102–103, 127–141 (2016)

Cheng, C., Mahnken, R.: A multi-mechanism model for cutting simulation: a Ginzburg–Landau type phase gradient and numerical implementations. Int. J. Solids Struct. 160, 1–17 (2018)

Chiou, S.T., Cheng, W.C., Lee, W.S.: Strain rate effects on the mechanical properties of a Fe–Mn–Al alloy under dynamic impact deformations. Mater. Sci. Eng. A 392, 156–162 (2005)

Dudzinski, D., Molinari, A.: A modelling of cutting for viscoplastic materials. Int. J. Mech. Sci. 39(4), 369–389 (1997)

Ehlers, W.: A single-surface yield function for geomaterials. Arch. Appl. Mech. 65, 246–259 (1995)

Farrokh, B., Khan, A.S.: Grain size, strain rate, and temperature dependence of flow stress in ultra-fine grained and nanocrystalline Cu and Al: synthesis, experiment, and constitutive modeling. Int. J. P. 25, 715–732 (2009)

Forest, S., Ammar, K., Appolaire, B.: Micromorphic vs phase-field approaches for gradient viscoplasticity and phase transformations. Lect. Notes Appl. Comput. Mech. 59(2011), 69–88 (2011)

Haddag, B., Atlati, S., Nouari, M., Moufiki, A.: Dry machining aeronautical aluminum alloy AA2024-T351: analysis of cutting forces, chip segmentation and built-up edge formation. Alumin. Alloys 6(9), 197 (2016)

Hallberg, H., Hakansson, P., Ristimaa, M.: A constitutive model for the formation of martensite in austenitic steels under large strain plasticity. Int. J. Plast. 23, 1213–1239 (2007)

Haupt, P.: Continuum Mechanics and Theory of Materials. Springer, Berlin (2002)

He, A., Xie, G., Zhang, H., Wang, X.: A modified Zerilli–Armstrong constitutive model to predict hot deformation behavior of 20CrMo alloy steel. Mater. Des. 56, 122–127 (2014)

Hortig, C.: Local and Non-local Thermomechanical Modeling and Finite-element Simulation of High-speed Cutting, Dissertation, University of Dortmund (2010)

Ivanov, I.M.: Simulationsmodell als Basis zur Ableitung von Zerspanstrategien zur Reduzierung von thermischen Bearbeitungseinflssen beim Hartdrehen, Dissertation, TU Berlin, Germany (2017)

Jaspers, S.P.F.C., Dautzenberg, J.H.: Material behaviour in conditions similar to metal cutting: flow stress in the primary shear zone. Int. J. Mater. Process. Technol. 122, 322–330 (2002)

Johnson, G.R.; Cook, W.H.: A constitutive model and data for metals subjected to large strain rates and high temperatures. In: Proceedings of the 7th International Symposium on Ballistics. The Hague, pp. 541–547 (1983)

Khan, A.S., Zhang, H., Takacs, L.: Mechanical response and modeling of fully compacted nanocrystalline iron and copper. Int. J. Plast. 16, 1459–1476 (2000)

Leblond, J.B.: Mathematical modelling of transformation plasticity in steels II: coupling with strain hardening phenomena. Int. J. Plast. 5, 537–591 (1989)

Levitas, A.V., Idesman, A.V., Olson, G.B.: Continuum modeling of strain-induced martensitic phase transformation at shear-band intersections. Acta Mater. 47(1), 219–233 (1998)

Li, H.Y., Khan, H., Wang, X.F., Wei, D.D., Hu, J.D., Li, Y.H.: A comparative study on modified Zerilli–Armstrong, Arrhenius-type and artificial neural network models to predict high-temperature deformation behavior in T24 steel. Mater. Sci. Eng. A 536, 216–222 (2012)

Liang, R., Khan, A.S.: A critical review of experimental results and constitutive models for BCC and FCC metals over a wide range of strain rates and temperatures. Int. J. Plast. 15, 963–980 (1999)

Lin, Y., Chen, X.: A combined Johnson–Cook and Zerilli–Armstrong model for hot compressed typical high-strength alloy steel. Comput. Mater. Sci. 49(3), 628–633 (2010)

Mahnken, R.: Theoretical, numerical and identification aspects of a new model class for ductile damage. Int. J. Plast. 18, 801–831 (2002)

Mahnken, R.: Creep simulation of asymmetric effects by use of stress mode dependent weighting functions. Int. J. Solids Struct. 40, 6189–6209 (2003)

Mahnken, R.: Void growth in finite deformation elasto-plasticity due to hydrostatic stress states. Comput. Methods Appl. Mech. Eng. 194, 3689–3709 (2005)

Mahnken, R.: Identification of material parameters for constitutive equations. In: Encyclopedia of Computational Mechanics Second Edition. Wiley (2017)

Mahnken, R., Schneidt, A., Antretter, T.: Macro modelling and homogenization for transformation induced plasticity of a low-alloy steel. Int. J. Plast. 25, 183–204 (2009)

Mahnken, R., Wolff, M., Schneidt, A., Böhm, M.: Multi-phase transformations at large strains—thermodynamic framework and simulation. Int. J. Plast. 39, 1–26 (2012)

Mahnken, R., Wolff, M., Cheng, C.: A multi-mechanism model for cutting simulations combining visco-plastic asymmetry and phase transformation. Int. J. Solids Struct. 50, 3045–3066 (2013)

Marusich, T., Ortiz, M.: Modelling and simulation of high-speed machining. Int. J. Numer. Methods Eng. 38, 3675–3694 (1995)

Oxley, P.L.B.: Mechanics of Machining, an Analytical Approach to Assessing Machinability. Ellis Horwood Ltd., Chichester (1989)

Ozel, T., Zeren, E.: Determination of work material flow stress and friction for FEA of machining using orthogonal cutting tests. J. Mater. Process. Technol. 153–154, 1019–1025 (2004)

Preston, D.L., Tonks, D.L., Wallace, D.C.: Model of plastic deformation for extreme loading conditions. J. Appl. Phys. 93, 211–220 (2003)

Samantaray, D., Mandal, S., Borah, U., Bhaduri, A.K., Sivaprasad, P.V.: A thermo-viscoplastic constitutive model to predict elevated-temperature flow behaviour in a titanium-modified austenitic stainless steel. Mater. Sci. Eng. A 526, 1–6 (2009)

Samantaray, D., Mandal, S., Bhaduri, A.K.: A comparative study on Johnson–Cook, modified Zerilli–Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behaviour in modified 9Cr–1Mo steel. Comput. Mater. Sci. 47(2), 568–576 (2009)

Sartkulvanich, P., Koppka, F., Altan, T.: Determination of flow stress for metal cut-ting simulation A progress report. J. Mater. Process. Technol. 146, 61–71 (2004)

Shi, B., Attia, H., Tounsi, N.: Identification of material constitutive laws for machining part I: an analytical model describing the stress, strain, strain rate, and temperature fields in the primary shear zone in orthogonal metal cutting. J. Manuf. Sci. Eng. 132, 051008-1 (2010)

Simo, J.C., Hughes, T.J.R.: Computational Inelasticity, Interdisciplinary Applied Mathematics, vol. 7. Mechanics and Materials. Springer (1998)

Stouffer, D.C., Dame, L.T.: Inelastic Deformation of Metals. Wiley, New York (1996)

Spencer, A.J.M.: Theory of invariants. In: Eringen, A.C. (ed.) Continuum Physics, vol. 1. Academic press, New York (1971)

Spitzig, W.A., Sober, R.J., Richmond, O.: Pressure dependence of yielding and associated volume expansion in tempered martensite. Acta Metall. 23, 885–893 (1975)

Umbrello, D., Saoubi, R.M., Outeiro, J.C.: The influence of Johnson–Cook material constants on finite element simulation of machining of AISI 316L steel. Int. J. Mach. Tools Manuf. 47, 462–470 (2007)

Voyiadjis, G.Z., Abed, F.H.: Microstructural based models for BCC and FCC metals with temperature and strain rate dependency. Mech. Mater. Mech. Mater. 37(2–3), 355–378 (2005)

Voyiadjis, G.Z., Almasri, A.H.: A physically based constitutive model for FCC metals with applications to dynamic hardness. Mech. Mater. 40, 549–563 (2008)

Zerilli, F.J., Armstrong, R.W.: Dislocation-mechanics-based constitutive relations for material dynamics calculations. J. Appl. Phys. 61(5), 1816 (1987)

Zerilli, F.J.: Dislocation-mechanics-based constitutive equations. Metall. Mater. Trans. A 35, 2547–2555 (2004)

Zhan, H.Y., Wang, G., Kent, D., Dargusch, M.: Constitutive modelling of the flow behaviour of a titanium alloy at high strain rates and elevated temperatures using the Johnson–Cook and modified Zerilli–Armstrong models. Mater. Sci. Eng. A 612, 71–79 (2014)

Acknowledgements

This paper is an extension of the research work based on investigations of priority point program 1480 (SPP 1480), which is kindly supported by the Deutsche Forschungsgemeinschaft (DFG).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A: Mechanical tests of steel AISI 52100

Appendix A: Mechanical tests of steel AISI 52100

In order to identify the asymmetric visco-plasticity of the studied material steel AISI 52100, we use the existing mechanical data as given in [9], where the thermal-mechanical tests are investigated in a big range of strain rates and temperatures as listed in Table 4.

The experimental results are shown in Fig. 21; the inelastic asymmetry, where the inelastic behaviours are different under tension, compression, and torsion tests, is proved. Otherwise, the material shows significant dependence on temperature and strain rate.

Rights and permissions

About this article

Cite this article

Cheng, C., Mahnken, R. A modified Zerilli–Armstrong model as the asymmetric visco-plastic part of a multi-mechanism model for cutting simulations. Arch Appl Mech 91, 3869–3888 (2021). https://doi.org/10.1007/s00419-021-01982-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-021-01982-6