Abstract

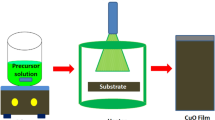

The present work demonstrates a comparison of performance of Cu, In and Ga-doped CdSe thin films-based photodetectors. Structural, morphological, optical and electrical investigation of Cu, In and Ga-doped CdSe thin films prepared by close space sublimation on glass slides is also achieved. It is obtained that Cu, In and Ga-doped CdSe thin films have a good crystal quality with a hexagonal structure in the preferred orientation along (002) plane. Morphological examination shows that Cu-doped CdSe thin films grow in the porous microstructure while In and Ga-doped CdSe films possess compact and uniform morphology without any voids. Transparency of In and Ga-doped CdSe films are higher than that of Cu-doped CdSe throughout the entire spectrum. Band gap values of all the samples are determined to be almost 1.72 eV. Photoluminescence data indicate that Ga-doped CdSe thin films display a deep level band at the lowest peak intensity, which is the indication of less defected structure. All the samples exhibit n-type conductivity. Additionally, the maximum carrier density and the minimum resistivity are reached for In-doped CdSe thin films as 1.75 × 1016 cm−3 and 6.12 Ω cm, respectively. Rise time of 28 ms and fall time of 25 ms are obtained for Cu-doped CdSe thin films-based photodetector, which are the fastest photoresponse within all the devices. Furthermore, Cu-doped CdSe thin films-based device has a responsivity of 1.20 × 10–2 A/W and a detectivity of 1.20 × 109 Jones that makes Cu-doped CdSe thin films-based device as a strong candidate for high sensitive photodetector applications.

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in this published article.

References

P. Chauhan, A.B. Patel, S. Narayan, J. Prasad, C.K. Sumesh, G.K. Solanki, K.D. Patel, S.S. Soni, P.K. Jha, V.M. Pathak, V. Patel, J. Alloys Compd. 862, 158017 (2021). https://doi.org/10.1016/j.jallcom.2020.158016

S. Sadeghi, S.K. Abkenar, C.W. Ow-Yang, S. Nizamoglu, Sci. Rep. 9, 10061 (2019). https://doi.org/10.1038/s41598-019-46581-2

N.G. Patel, C.J. Panchal, K.K. Makhija, Cryst. Res. Technol. 29, 1013 (1994). https://doi.org/10.1002/crat.2170290717

M.M. Rahman, M.R. Karim, H.F. Alharbi, B. Aldokhayel, T. Uzzaman, H. Zahir, Chem. Asian J. 16, 902 (2021). https://doi.org/10.1002/asia.202001369

N.T. Shelke, S.C. Karle, B.R. Karche, J. Mater. Sci: Mater. Electron. 31, 15061 (2020). https://doi.org/10.1007/s10854-020-04069-0

E. Bacaksiz, B.M. Basol, M. Altunbaş, S. Yılmaz, M. Tomakin, B. Abay, Stat. Sol. (b) 244, 497 (2007). https://doi.org/10.1002/pssb.200642207

D. Kumar, C. Lal, D. Veer, D. Singh, P. Kumar, R.S. Katiyar, Phys. Scr. 98, 055930 (2023). https://doi.org/10.1088/1402-4896/accabc

S.S. Kulkarni, U.P. Gawai, S.D. Kamble, D.P. Upasani, J.V. Sali, R. Venkatesh, D.S. Bhavsar, J. Mater. Sci: Mater. Electron. 52, 3352 (2023). https://doi.org/10.1007/s11664-023-10310-3

H. Ilchuk, R. Petrus, A. Kashuba, I. Semkiv, E. Zmiiovska, Mol. Cryst. Liq. 699, 1 (2020). https://doi.org/10.1080/15421406.2020.1732532

S. Kumar, S. Valanarasu, K.V. Gunavathy, S. Vinoth, K. Haunsbhavi, D. Alagarasan, K.D.A. Kumar, M. Ubaidullah, S.F. Shaikh, B. Pandit, Phys. Scr. 97, 055807 (2022). https://doi.org/10.1088/1402-4896/ac619c

Y. Jiang, W.J. Zhang, J.S. Jie, X.M. Meng, X. Fan, S.-T. Lee, Adv. Funct. Mater. 17, 1795 (2007). https://doi.org/10.1002/adfm.200600351

E. Shalev, E. Oksenberg, K. Rechav, R. Popovitz-Biro, E. Joselevich, ACS Nano 11, 213 (2017). https://doi.org/10.1021/acsnano.6b04469

Q. An, X. Meng, K. Xiong, Y. Qiu, W. Lin, J. Alloys Compd. 726, 214 (2017). https://doi.org/10.1016/j.jallcom.2017.07.336

A.M. Smirnov, A.D. Golinskaya, P.A. Kotin, S.G. Dorofeev, V.V. Palyulin, V.N. Mantsevich, V.S. Dneprovskii, J. Lumin. 213, 29 (2019). https://doi.org/10.1016/j.jlumin.2019.05.001

H. Luo, C. Tuinenga, E.B. Guidez, C. Lewis, J. Shipman, S. Roy, C.M. Aikens, V. Chikan, J. Phys. Chem. C 119, 10749 (2015). https://doi.org/10.1021/acs.jpcc.5b01963

S.N. Moger, M.G. Mahesha, Micro Nanostruct. 168, 207335 (2022). https://doi.org/10.1016/j.micrna.2022.207335

Z. Hu, X. Zhang, C. Xie, C. Wu, X. Zhang, L. Bian, Y. Wu, L. Wang, Y. Zhang, J. Jie, Nanoscale 3, 4798 (2011). https://doi.org/10.1039/c1nr10619h

J. Qiu, Y. Liu, Z. Cai, Q. Phan, Z. Shi, Mater. Adv. 3, 1079 (2022). https://doi.org/10.1039/d1ma00760b

K. Sharma, Poonam, G.S.S. Saini, S.K. Tripathi, J. Mater. Sci: Mater. Electron. 29, 9596 (2018). https://doi.org/10.1007/s10854-018-8995-2

V.S. Raut, C.D. Lokhande, V.V. Killedar, J Mater Sci: Mater Electron 28, 3140 (2017). https://doi.org/10.1007/s10854-016-5902-6

H.G. Chasta, D. Suthar, A. Thakur, M.D. Kannan, M.S. Dhaka, Mater. Res. Bull. 152, 111845 (2022). https://doi.org/10.1016/j.materresbull.2022.111845

V.S. Raut, C.D. Lokhande, H.D. Shelke, V.V. Killedar, J. Mater. Sci.: Mater. Electron. 33, 13782 (2022). https://doi.org/10.1007/s10854-022-08310-w

W.J. Aziz, Mater. Res. Bull. 42, 148 (2019). https://doi.org/10.1007/s12034-019-1830-4

S.B. Singh, M.V. Limaye, N.P. Lalla, S.K. Kulkarni, J. Lumin. 128, 1909 (2008). https://doi.org/10.1016/j.jlumin.2008.05.022

M.G.S.A. Basheer, K.S. Rajni, V.S. Vidhya, V. Swaminathan, A. Thayumanavan, K.R. Murali, M. Jayachandran, Cryst. Res. Technol. 46, 261 (2011). https://doi.org/10.1002/crat.201000546

S. Kumar, T.T. John, Mater. Chem. Phys. 286, 126222 (2022). https://doi.org/10.1016/j.matchemphys.2022.126222

A.A. Hussain, B. Sharma, T. Barman, A.R. Pal, A.C.S. Appl, Mater. Interfaces 8, 4258 (2016). https://doi.org/10.1021/acsami.6b00249

X. Li, Q. Tan, X. Feng, Q. Wang, Y. Liu, Nanoscale Res. Lett. 13, 171 (2018). https://doi.org/10.1186/s11671-018-2590-6

T. Takahashi, P. Nichols, K. Takei, A.C. Ford, A. Jamshidi, M.C. Wu, C.Z. Ning, A. Javey, Nanotechnology 23, 045201 (2012). https://doi.org/10.1088/0957-4484/23/4/045201

G. Li, Y. Jiang, Y. Zhang, X. Lan, T. Zhai, G.-C. Yi, J. Mater. Chem. C 2, 8252 (2014). https://doi.org/10.1039/C4TC01503G

L. Zhang, H. Yu, W. Cao, Y. Dong, C. Zou, Y. Yang, S. Huang, N. Dai, D.-M. Zhu, Appl. Surf. Sci. 307, 608 (2014). https://doi.org/10.1016/j.apsusc.2014.04.085

C.P. Veeramalai, P. Kollu, G. Lin, X. Zhang, C. Li, Nanotechnology 32, 315204 (2021). https://doi.org/10.1088/1361-6528/abf87a

L. Du, Y. Lei, Mater. Lett. 106, 100 (2013). https://doi.org/10.1016/j.matlet.2013.04.107

Author information

Authors and Affiliations

Contributions

All authors contributed to the study. Materials preparation, fabrication of devices and electrical characterization were performed by İP, TK and EB. The other characterizations were carried out by MT. The interpretations of results were realized by SY and EB. The manuscript was written by SY. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yılmaz, S., Polat, İ., Tomakin, M. et al. CdSe thin films-based photodetector doped with Cu, In and Ga atoms: a comparative work. Appl. Phys. A 129, 569 (2023). https://doi.org/10.1007/s00339-023-06860-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-023-06860-2