Abstract

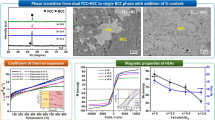

The effect of Al and Si on microstructure evolution, mechanical, magnetic properties, and electrical resistivity of non-equimolar Fe2CoNi(AlSi)x (x = 0–0.4) high-entropy alloys (HEAs) was studied. This series of Fe2CoNi(AlSi)x HEAs has a dual-phase structure and shows an excellent combination of mechanical and soft magnetic properties. In particular, the Fe2CoNi(AlSi)0.4 HEA exhibits high compressive yield strength σ0.2 (887.6 MPa), fracture strain (39%), electrical resistivity ρ (84.8 μΩ cm), Ms (155.2 emu/g), and Hc (1.7 Oe). This work may provide a promising method of developing HEAs with an optimal balance of mechanical and soft magnetic properties under the addition of Al and Si suitable for wide-range industrial applications.

Similar content being viewed by others

References

A. Krings, A. Boglietti, A. Cavagnino, S. Sprague, IEEE Trans. Ind. Electron. 64, 2405 (2017). https://doi.org/10.1109/TIE.2016.2613844

X. Yan, Y. Zhang, Scr. Mater. 187, 188 (2020). https://doi.org/10.1016/j.scriptamat.2020.06.017

G. Herzer, Acta Mater. 61, 718 (2013). https://doi.org/10.1016/j.actamat.2012.10.040

T.D. Shen, S.W. Xin, B.R. Sun, J. Alloys Compd. 658, 703 (2016). https://doi.org/10.1016/j.jallcom.2015.10.260

J.T. Kim, S.H. Hong, J.M. Park, J. Eckert, K.B. Kim, J. Mater. Sci. Technol. 43, 135 (2020). https://doi.org/10.1016/j.jmst.2020.01.004

B. Cantor, I.T.H. Chang, P. Knight, A.J.B. Vincent, Mater. Sci. Eng. A 375, 213 (2004). https://doi.org/10.1016/j.msea.2003.10.257

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004). https://doi.org/10.1002/adem.200300567

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Prog. Mater. Sci. 61, 1 (2014). https://doi.org/10.1016/j.pmatsci.2013.10.001

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, R.O. Ritchie, Science 345, 1153 (2014). https://doi.org/10.1126/science.1254581

Y. Lu, Y. Dong, H. Jiang, Z. Wang, Z. Cao, S. Guo, T. Wang, T. Li, P.K. Liaw, Scr. Mater. 187, 202 (2020). https://doi.org/10.1016/j.scriptamat.2020.06.022

M. Wang, H. Cui, Y. Zhao, C. Wang, Na. Wei, Y. Zhao, X. Zhang, Q. Song, Mater. Des. 180, 107983 (2019). https://doi.org/10.1016/j.matdes.2019.107893

E.P. George, D. Raabe, R.O. Ritchie, Nat. Rev. Mater. 4, 515 (2019). https://doi.org/10.1038/s41578-019-0121-4

A. Takeuchi, K. Amiya, T. Wada, K. Yubuta, W. Zhang, JOM 66, 1984 (2014). https://doi.org/10.1007/s11837-014-1085-x

J. Miao, H. Liang, A. Zhang, J. He, J. Meng, Y. Lu, Tribol. Int. 153, 106599 (2021). https://doi.org/10.1016/j.triboint.2020.106599

H. Liang, D. Qiao, J. Miao, Z. Cao, H. Jiang, T. Wang, J. Mater. Sci. Technol. 85, 224 (2021). https://doi.org/10.1016/j.jmst.2020.12.050

M.C. Gao, D.B. Miracle, D. Maurice, X. Yan, Y. Zhang, J.A. Hawk, J. Mater. Res. 33, 3138 (2018). https://doi.org/10.1557/jmr.2018.323

Q. Ding, Y. Zhang, X. Chen, X. Fu, D. Chen, S. Chen, L. Gu, F. Wei, H. Bei, Y. Gao, Nature 574, 223 (2019). https://doi.org/10.1038/s41586-019-1617-1

J. Cieslak, J. Tobola, M. Reissner, Intermetallics 118, 106672 (2020). https://doi.org/10.1016/j.intermet.2019.106672

M.S.K.K. Nartu, A. Jagetia, V. Chaudhary, S.A. Mantri, E. Ivanov, N.B. Dahotre, R.V. Ramanujan, R. Banerjee, Scr. Mater. 187, 30 (2020). https://doi.org/10.1016/j.scriptamat.2020.05.063

T.T. Zuo, R.B. Li, X.J. Ren, Y. Zhang, J. Magn. Magn. Mater. 371, 60–68 (2014). https://doi.org/10.1016/j.jmmm.2014.07.023

Y. Zhang, T. Zuo, Y. Cheng, P.K. Liaw, Sci. Rep. 3, 1455 (2013). https://doi.org/10.1038/srep01455

T. Zuo, M.C. Gao, L. Ouyang, X. Yang, Y. Cheng, R. Feng, S. Chen, P.K. Liaw, J.A. Hawk, Y. Zhang, Acta Mater. 130, 10 (2017). https://doi.org/10.1016/j.actamat.2017.03.013

K.X. Zhou, B.R. Sun, G.Y. Liu, X.W. Li, S.W. Xin, P.K. Liaw, T.D. Shen, Intermetallics 122, 106801 (2020). https://doi.org/10.1016/j.intermet.2020.106801

Q. Zhang, H. Xu, X.H. Tan, X.L. Hou, S.W. Wu, G.S. Tan, L.Y. Yu, J. Alloys Compd. 693, 1061 (2017). https://doi.org/10.1016/j.jallcom.2016.09.271

L. Jiang, Y. Lu, Y. Dong, T. Wang, Z. Cao, T. Li, Appl. Phys. A. Mater. Sci. Process. 119, 291 (2015). https://doi.org/10.1007/s00339-014-8964-4

H. Zhang, Y. Yang, L. Liu, C. Chen, T. Wang, R. Wei, T. Zhang, Y. Dong, F. Li, J. Magn. Magn. Mater. 478, 116 (2019). https://doi.org/10.1016/j.jmmm.2019.01.096

T. Zuo, M. Zhang, P.K. Liaw, Y. Zhang, Intermetallics 100, 1 (2018). https://doi.org/10.1016/j.intermet.2018.05.014

Z. Li, Y. Gu, M. Pan, C. Wang, Z. Wu, X. Hou, X. Tan, H. Xu, J. Alloys Compd. 792, 215 (2019). https://doi.org/10.1016/j.jallcom.2019.03.411

P. Li, A. Wang, C.T. Liu, Intermetallics 87, 21 (2017). https://doi.org/10.1016/j.intermet.2017.04.007

B. Zhang, Y. Duan, X. Wen, G. Ma, T. Wang, X. Dong, H. Zhang, N. Jia, Y. Zeng, J. Alloys Compd. 790, 179 (2019). https://doi.org/10.1016/j.jallcom.2019.03.152

T. Borkar, B. Gwalani, D. Choudhuri, C.V. Mikler, C.J. Yannetta, X. Chen, R.V. Ramanujan, M.J. Styles, M.A. Gibson, R. Banerjee, Acta Mater. 116, 63 (2016). https://doi.org/10.1016/j.actamat.2016.06.025

X. Chang, M. Zeng, K. Liu, L. Fu, Adv. Mater. 32, 1907226 (2020). https://doi.org/10.1002/adma.201907226

C. Liu, W. Peng, C.S. Jiang, H. Guo, J. Tao, X. Deng, Z. Chen, J. Mater. Sci. Technol. 35, 1175 (2019). https://doi.org/10.1016/j.jmst.2018.12.014

C. Jung, K. Kang, A. Marshal, K.G. Pradeep, J. Seol, H.M. Lee, P. Choi, Acta Mater. 171, 31 (2019). https://doi.org/10.1016/j.actamat.2019.04.007

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, P.K. Liaw, Adv. Eng. Mater. 10, 534 (2008). https://doi.org/10.1002/adem.200700240

X. Yang, Y. Zhang, Mater. Chem. Phys. 132, 233 (2012). https://doi.org/10.1016/j.matchemphys.2011.11.021

S. Guo, C. Ng, J. Lu, C.T. Liu, J. Appl. Phys. 109, 103505 (2011). https://doi.org/10.1063/1.3587228

Y. Zhang, M. Zhang, D. Li, T. Zuo, K. Zhou, M.C. Gao, B. Sun, T. Shen, Metals 9, 382 (2019). https://doi.org/10.3390/met9030382

Acknowledgements

This work was supported by National Key Research and Development Program of China (Nos. 2019YFA0209901 and 2018YFA0702901), Liao Ning Revitalization Talents Program (No. XLYC1807047), Fund of Science and Technology on Reactor Fuel and Materials Laboratory (No. 6142A06190304), and Fund of the State Key Laboratory of Solidification Processing in NWPU (No. SKLSP201902).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kang, T., Wu, S., Wang, M. et al. Novel Fe2CoNi(AlSi)x high-entropy alloys with attractive soft magnetic and mechanical properties. Appl. Phys. A 127, 829 (2021). https://doi.org/10.1007/s00339-021-04988-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04988-7