Abstract

The utilisation of additive manufacturing is essential in the production of intricate and complex parts that cannot be manufactured using traditional manufacturing methods. Despite the complexity of the manufacturing process, parts produced using techniques such as FDM and SLS may include imperfections that diminish the strength of the final products. Post-processing was necessary to increase their strength despite the fact that defects are unavoidable due to the use of advanced manufacturing techniques. Post-heat treatment of FDM- and SLS-printed specimens is assessed using mechanical testing and microscopic analysis. Both the FDM- and SLS-printed parts were discovered to be significantly impacted by post-heating, with the SLS-produced parts being more impacted. After undergoing the heat treatment process, the FDM-printed parts exhibited an average tensile strength of 39.11 MPa, a surface roughness of 2.13 µm, a Shore D hardness of 58.79, and a specific wear rate of 21.21 × 10–5 kg/Nm. After undergoing the heat treatment process, the SLS-printed parts exhibited an average tensile strength of 28.06 MPa, a surface roughness of 2.4 µm, a Shore D hardness of 49.48, and a specific wear rate of 17.49 × 10–5 kg/Nm. The FDM- and SLS-printed components' tensile and hardness properties increased by 21.98 and 6.5%, respectively. The FDM-printed parts' surface roughness and wear rate were lowered to 24.83 and 21.1%, while the SLS-printed parts' were reduced to 51.67 and 50.3%. It proved that SLS-printed components are highly influenced, and that thermal treatment dramatically improved their mechanical properties.

Similar content being viewed by others

Abbreviations

- PA12:

-

Polyamide 12

- FDM:

-

Fused deposition modelling

- SLS:

-

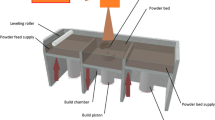

Selective laser sintering

- AM:

-

Additive manufacturing

- PLA:

-

Polylactic acid

- 3D printing:

-

Three-dimensional printing

- TPE:

-

Thermoplastic elastomer

- ABS:

-

Acrylonitrile butadiene styrene

- GF:

-

Glass fibre

- DMA:

-

Dynamic mechanical analysis

- ASTM:

-

American society for testing and materials

- UTM:

-

Universal testing machine

- EN:

-

European standard

- µm:

-

Micro metre

- FESEM:

-

Field emission scanning electron microscopy

References

Zīle E, Zeleniakiene DAA (2022) Characterization of polylactic acid parts produced using the fused deposition modelling. Mech Compos Mater 58:241–256. https://doi.org/10.22364/mkm.58.2.02

Mellal MA, Laifaoui C, Ghezal F, Williams EJ (2022) Multi-objective factors optimization in fused deposition modelling with particle swarm optimization and differential evolution. Int J Interact Des Manuf 16:1669–1674. https://doi.org/10.1007/s12008-022-00868-3

Gotkhindikar NN, Singh M, Kataria R (2023) Optimized deep neural network strategy for best parametric selection in fused deposition modelling. Int J Interact Des Manuf. https://doi.org/10.1007/s12008-023-01369-7

Colorado HA, Mendoza DE, Lin HT, Gutierrez-Velasquez E (2022) Additive manufacturing against the Covid-19 pandemic: a technological model for the adaptability and networking. J Mater Res Technol 16:1150–1164. https://doi.org/10.1016/j.jmrt.2021.12.044

Das AK, Agar DA, Rudolfsson M, Larsson SH (2021) A review on wood powders in 3D printing: processes, properties and potential applications. J Mater Res Technol 15:241–255. https://doi.org/10.1016/j.jmrt.2021.07.110

Colorado HA, Velásquez EIG, Monteiro SN (2020) Sustainability of additive manufacturing: the circular economy of materials and environmental perspectives. J Mater Res Technol 9:8221–8234. https://doi.org/10.1016/j.jmrt.2020.04.062

Tao Y, Kong F, Li Z et al (2021) A review on voids of 3D printed parts by fused filament fabrication. J Mater Res Technol 15:4860–4879. https://doi.org/10.1016/j.jmrt.2021.10.108

Musa L, Krishna Kumar N, Abd Rahim SZ et al (2022) A review on the potential of polylactic acid based thermoplastic elastomer as filament material for fused deposition modelling. J Mater Res Technol 20:2841–2858. https://doi.org/10.1016/j.jmrt.2022.08.057

Tambrallimath V, Keshavamurthy R, Davim P et al (2022) Synthesis and characterization of flyash reinforced polymer composites developed by fused filament fabrication. J Mater Res Technol 21:810–826. https://doi.org/10.1016/j.jmrt.2022.09.059

Alarifi IM (2022) A performance evaluation study of 3d printed nylon/glass fiber and nylon/carbon fiber composite materials. J Mater Res Technol 21:884–892. https://doi.org/10.1016/j.jmrt.2022.09.085

Ghaemi Khiavi S, Mohammad Sadeghi B, Divandari M (2022) Effect of topology on strength and energy absorption of PA12 non-auxetic strut-based lattice structures. J Mater Res Technol 21:1595–1613. https://doi.org/10.1016/j.jmrt.2022.09.116

Srivastava M, Rathee S, Patel V et al (2022) A review of various materials for additive manufacturing: Recent trends and processing issues. J Mater Res Technol 21:2612–2641. https://doi.org/10.1016/j.jmrt.2022.10.015

Solomon IJ, Sevvel P, Gunasekaran J (2020) A review on the various processing parameters in FDM. Mater Today Proc 37:509–514. https://doi.org/10.1016/j.matpr.2020.05.484

Lal Lazar PJ, Subramanian J, Natarajan E et al (2023) Anisotropic structure-property relations of FDM printed short glass fiber reinforced polyamide TPMS structures under quasi-static compression. J Mater Res Technol 24:9562–9579. https://doi.org/10.1016/j.jmrt.2023.05.167

Mehrpouya M, Vahabi H, Barletta M, et al (2021) Additive manufacturing of polyhydroxyalkanoates (PHAs) biopolymers: Materials, printing techniques, and applications. Mater Sci Eng C 127. https://doi.org/10.1016/j.msec.2021.112216

Lupone F, Padovano E, Casamento F, Badini C (2022) Process phenomena and material properties in selective laser sintering of polymers: A review. Materials (Basel) 15. https://doi.org/10.3390/ma15010183

Guessasma S, Belhabib S, Nouri H (2021) Effect of printing temperature on microstructure, thermal behavior and tensile properties of 3D printed nylon using fused deposition modeling. J Appl Polym Sci 138:1–15. https://doi.org/10.1002/app.50162

Zhang X, Fan W, Liu T (2020) Fused deposition modeling 3D printing of polyamide-based composites and its applications. Compos Commun 21:100413. https://doi.org/10.1016/j.coco.2020.100413

Lokesh N, Praveena BA, Sudheer Reddy J et al (2022) Evaluation on effect of printing process parameter through Taguchi approach on mechanical properties of 3D printed PLA specimens using FDM at constant printing temperature. Mater Today Proc 52:1288–1293. https://doi.org/10.1016/j.matpr.2021.11.054

Pulipaka A, Gide KM, Beheshti A, Bagheri ZS (2023) Effect of 3D printing process parameters on surface and mechanical properties of FFF-printed PEEK. J Manuf Process 85:368–386. https://doi.org/10.1016/j.jmapro.2022.11.057

Balan GS, Raj SA, Sridharan M, Adithya RN (2023) A study of the effect of printing process parameters on the delamination and surface finish properties of aluminium-infused PLA printed via material extrusion. Aust J Mech Eng 00:1–21. https://doi.org/10.1080/14484846.2023.2231131

Singhal P, Sujithra R, Saritha D (2022) Effect of alternate fill pattern on mechanical properties of FDM printed PC-PBT alloy. Mater Today Proc 62:3791–3799. https://doi.org/10.1016/j.matpr.2022.04.470

Dezaki ML, Mohd Ariffin MKA (2020) The effects of combined infill patterns on mechanical properties in fdm process. Polymers (Basel) 12:1–20. https://doi.org/10.3390/polym12122792

Algarni MSG (2021) Comparative study of the sensitivity of PLA, ABS, PEEK, and PETG’s mechanical properties to FDM printing process parameters. Crystals 11. https://doi.org/10.3390/cryst11080995

Xu Z, Wang Y, Wu D et al (2019) The process and performance comparison of polyamide 12 manufactured by multi jet fusion and selective laser sintering. J Manuf Process 47:419–426. https://doi.org/10.1016/j.jmapro.2019.07.014

Mehdipour F, Gebhardt U, Kästner M (2021) Anisotropic and rate-dependent mechanical properties of 3D printed polyamide 12—A comparison between selective laser sintering and multi jet fusion. Res Mater 11. https://doi.org/10.1016/j.rinma.2021.100213

Cai C, Tey WS, Chen J et al (2021) Comparative study on 3D printing of polyamide 12 by selective laser sintering and multi jet fusion. J Mater Process Technol 288:116882. https://doi.org/10.1016/j.jmatprotec.2020.116882

Glaskova-Kuzmina T, Dejus D, Jātnieks J et al (2022) Flame-retardant and tensile properties of polyamide 12 processed by selective laser sintering. J Comp Sci 6. https://doi.org/10.3390/jcs6070185

Morano C, Alfano M (2023) Effect of strain rates and heat exposure on polyamide ( PA12 ) processed via selective laser sintering. Materials (Basel) 16:4654. https://doi.org/10.3390/ma16134654

Yang F, Jiang T, Lalier G et al (2021) Process control of surface quality and part microstructure in selective laser sintering involving highly degraded polyamide 12 materials. Polym Test 93:106920. https://doi.org/10.1016/j.polymertesting.2020.106920

Petzold S, Klett J, Schauer A, Osswald TA (2019) Surface roughness of polyamide 12 parts manufactured using selective laser sintering. Polym Test 80:106094. https://doi.org/10.1016/j.polymertesting.2019.106094

Jain M, Patil S (2022) Comparative analysis of surface characteristics of Nylon based polymer gears manufactured by different techniques. Mater Today Proc 63:40–45. https://doi.org/10.1016/j.matpr.2022.02.050

Ramesh M, Panneerselvam K (2019) Mechanical investigation and optimization of parameter selection for Nylon material processed by FDM. Mater Today Proc 46:9303–9307. https://doi.org/10.1016/j.matpr.2020.02.697

Baserinia R, Brockbank K, Dattani R (2022) Correlating polyamide powder flowability to mechanical properties of parts fabricated by additive manufacturing. Powder Technol 398:117147. https://doi.org/10.1016/j.powtec.2022.117147

Yu G, Ma J, Li J, et al (2022) Mechanical and Tribological Properties of 3D printed polyamide 12 and SiC/PA12 composite by selective laser sintering. Polymers (Basel) 14:. https://doi.org/10.3390/polym14112167

Luo M, He Q, Wang H, Chang L (2021) Tribological behavior of surface textured short carbon fiber- reinforced nylon composites fabricated by three-dimensional printing techniques. J Tribol 143:4050372. https://doi.org/10.1115/1.4050372

Balan GS, Raj SA (2023) Impact of freeze-thaw cycles on the mechanical performance of palm seed powder-modified flax-fibre reinforced polymer composites. J Polym Environ. https://doi.org/10.1007/s10924-023-02961-4

Kalani A, Vadher J, Sharma S, Jani R (2022) Investigation of thermal and wear behaviour of 3D printed PA-12 nylon polymer spur gears. El-Cezeri J Sci Eng 9:1121–1135. https://doi.org/10.31202/ecjse.1085328

Jayanth N, Jaswanthraj K, Sandeep S et al (2021) Effect of heat treatment on mechanical properties of 3D printed PLA. J Mech Behav Biomed Mater 123:104764. https://doi.org/10.1016/j.jmbbm.2021.104764

Kumar Jain PA, Sattar S, Mulqueen D et al (2022) Role of annealing and isostatic compaction on mechanical properties of 3D printed short glass fiber nylon composites. Addit Manuf 51:102599. https://doi.org/10.1016/j.addma.2022.102599

Valvez S, Reis PNB, Ferreira JAM (2023) Effect of annealing treatment on mechanical properties of 3D-Printed composites. J Mater Res Technol 23:2101–2115. https://doi.org/10.1016/j.jmrt.2023.01.097

Hashmi AW, Mali HS, Meena A et al (2023) A comprehensive review on surface post-treatments for freeform surfaces of bio-implants. J Mater Res Technol 23:4866–4908. https://doi.org/10.1016/j.jmrt.2023.02.007

Stojković JR, Turudija R, Vitković N et al (2023) An experimental study on the impact of layer height and annealing parameters on the tensile strength and dimensional accuracy of FDM 3D printed parts. Materials (Basel) 16:4574. https://doi.org/10.3390/ma16134574

Yang F, Jiang T, Lalier G et al (2020) A process control and interlayer heating approach to reuse polyamide 12 powders and create parts with improved mechanical properties in selective laser sintering. J Manuf Process 57:828–846. https://doi.org/10.1016/j.jmapro.2020.07.051

Sperry, M, Busath, A, Ottesen, M, Heslington, J, Crane N (2021) Post-processing and material properties of nylon 12 prepared by laser-powder bed fusion. In: Proceedings of the ASME 2021 International mechanical engineering congress and exposition. ASME International, pp 1–5

Chalgham A, Ehrmann A, Wickenkamp I (2021) Mechanical properties of fdm printed pla parts before and after thermal treatment. Polymers (Basel) 13:. https://doi.org/10.3390/polym13081239

Wang P, Zou B (2022) Improvement of heat treatment process on mechanical properties of FDM 3D-printed short-and continuous-fiber-reinforced PEEK composites. Coatings 12. https://doi.org/10.3390/coatings12060827

Razaviye MK, Tafti RA, Khajehmohammadi M (2022) An investigation on mechanical properties of PA12 parts produced by a SLS 3D printer: an experimental approach. CIRP J Manuf Sci Technol 38:760–768. https://doi.org/10.1016/j.cirpj.2022.06.016

da Silva TF, de Melo Morgadodo Amaral Montanheiro TL, GF et al (2020) A simple mixing method for polyamide 12/attapulgite nanocomposites: structural and mechanical characterization. SN Appl Sci 2:1–11. https://doi.org/10.1007/s42452-020-2153-1

Li S, Yang Y, Zha X et al (2018) Nanoscale morphology, interfacial hydrogen bonding, confined crystallization and greatly improved toughness of polyamide 12/polyketone blends. Nanomaterials 8. https://doi.org/10.3390/nano8110932

Ma N, Liu W, Ma L et al (2020) Crystal transition and thermal behavior of Nylon 12. E-Polymers 20:346–352. https://doi.org/10.1515/epoly-2020-0039

Czelusniak T, Amorim FL (2020) Influence of energy density on selective laser sintering of carbon fiber-reinforced PA12. Int J Adv Manuf Technol 111:2361–2376. https://doi.org/10.1007/s00170-020-06261-2

Yang F, Jiang T, Chen X et al (2021) A control of surface quality in selective laser sintering additive manufacturing with reclaimed polyamide materials. Solid Free Fabr 2021 Proc 23rd Annu Int Solid Free Fabr Symp—An Addit Manuf Conf, pp 645–656

Martynková GS, Slíva A, Kratošová G, et al (2021) Polyamide 12 materials study of morpho-structural changes during laser sintering of 3d printing. Polymers (Basel) 13. https://doi.org/10.3390/polym13050810

Omar MR, Abdullah MIHC, Alkahar MR, et al (2022) Effect of polyamide-12 material compositions on mechanical properties and surface morphology of SLS 3D printed part. J Mech Eng 19:57–70. https://doi.org/10.24191/jmeche.v19i1.19686

Meng Q, Song X, Han S et al (2022) Mechanical and functional properties of polyamide/graphene nanocomposite prepared by chemicals free-approach and selective laser sintering. Compos Commun 36:101396. https://doi.org/10.1016/j.coco.2022.101396

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the author(s).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Balan, G.S., Raj, S.A. & Adithya, R.N. Effect of post-heat treatment on the mechanical and surface properties of nylon 12 produced via material extrusion and selective laser sintering processes. Polym. Bull. (2024). https://doi.org/10.1007/s00289-024-05197-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00289-024-05197-x