Abstract

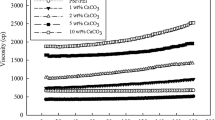

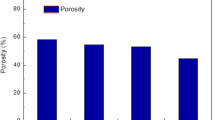

Polyvinylchloride (PVC)/poly(methyl methacrylate) (PMMA) blend membranes were prepared via the non-solvent-induced phase separation method to separate oil-in-water emulsion in a laboratory-scale cross-flow system. Free radical polymerization of methyl methacrylate was used to synthesize PMMA. The fabricated membranes were evaluated using a set of techniques including field emission scanning electron microscope (FESEM), thermogravimetric analysis (TGA), atomic force microscopy, pure water flux, contact angle, and pore size distribution. The FESEM results showed that with the increase of PMMA content in the casting solution, larger macro-voids in the porous substructure have appeared, surface pores of the membranes shifted toward smaller pores, and the number of surface pores of the membranes increased. Moreover, pure water flux was increased from 157.75 L m−2 h−1 for pure PVC membrane to 1036.25 L m−2 h−1 for 0.08 wt.% PMMA blend membrane because the hydrophilicity as well as the number of pores on the surface of 0.08 wt.% PMMA was higher than that of pure PVC membrane. In addition, the results of TGA analysis revealed that the degradation temperatures shifted toward higher temperatures as the PMMA content increased. Finally, the filtration of synthetic oily wastewater was performed to evaluate membrane performances, and it was revealed that PVC/PMMA blend membranes exhibited higher turbidity removal efficiency and lower flux decline during the filtration process. This indicates that the fouling resistance properties of blend membranes improved because of the presence of PMMA and its hydrophilic effects.

Similar content being viewed by others

References

Kazemi F, Jafarzadeh Y, Masoumi S, Rostamizadeh M (2021) Oil-in-water emulsion separation by PVC membranes embedded with GO-ZnO nanoparticles. J Environ Chem Eng 9:104992

Zhao L, Li R, Xu R, Si D, Shang Y, Ye H, Zhang Y, Ye H, Xin Q (2020) Antifouling slippery liquid-infused membrane for separation of water-in-oil emulsions. J Membrane Sci 118289

Wang R, Zhao X, Lan Y, Liu L, Gao C (2020) In situ metal-polyphenol interfacial assembly tailored superwetting PES/SPES/MPN membranes for oil-in-water emulsion separation. J Membr Sci 615:118566

Yin Y, Zhu L, Guo T, Qiao X, Gan S, Chang X, Li X, Xia F, Xue Q (2020) Microphone-like Cu-CAT-1 hierarchical structures with ultra-low oil adhesion for highly efficient oil/water separation. Sep Purif Technol 241:116688

Woo S, Cho H, Park J, Shin Y, Hwang W (2020) A novel approach to designing a biomimetic wettable patterned surface for highly efficient and continuous surfactant-free oil emulsion separation. Sep Purif Technol 248:116864

Fallahi A, Rezvani F, Asgharnejad H, Khorshidi E, Hajinajaf N, Higgins B (2021) Interactions of microalgae-bacteria consortia for nutrient removal from wastewater: a review. Chemosphere 129878

Painmanakul P, Sastaravet P, Lersjintanakarn S, Khaodhiar S (2010) Effect of bubble hydrodynamic and chemical dosage on treatment of oily wastewater by Induced Air Flotation (IAF) process. Chem Eng Res Des 88:693–702

Golshenas A, Sadeghian Z, Ashrafizadeh SN (2020) Performance evaluation of a ceramic-based photocatalytic membrane reactor for treatment of oily wastewater. J Water Process Eng 36:101186

Ong C, Lau W, Goh P, Ng B, Ismail A (2014) Investigation of submerged membrane photocatalytic reactor (sMPR) operating parameters during oily wastewater treatment process. Desalination 353:48–56

Yang C-L (2007) Electrochemical coagulation for oily water demulsification. Sep Purif Technol 54:388–395

Fallahi A, Hajinajaf N, Tavakoli O, Sarrafzadeh MH (2020) Cultivation of mixed microalgae using municipal wastewater: biomass productivity, nutrient removal, and biochemical content. Iran J Biotechnol 18:e2586

Govinna N, Sadeghi I, Asatekin A, Cebe P (2019) Thermal properties and structure of electrospun blends of PVDF with a fluorinated copolymer. J Polym Sci Part B: Polym Phys 57:312–322

Khakpour S, Jafarzadeh Y, Yegani R (2019) Incorporation of graphene oxide/nanodiamond nanocomposite into PVC ultrafiltration membranes. Chem Eng Res Des 152:60–70

Kang G-D, Cao Y-M (2014) Application and modification of poly (vinylidene fluoride)(PVDF) membranes: a review. J Membr Sci 463:145–165

Meng H, Cheng Q, Li C (2014) Polyacrylonitrile-based zwitterionic ultrafiltration membrane with improved anti-protein-fouling capacity. Appl Surf Sci 303:399–405

Van Tran TT, Kumar SR, Nguyen CH, Lee JW, Tsai H-A, Hsieh C-H, Lue SJ (2021) High-permeability graphene oxide and poly (vinyl pyrrolidone) blended poly (vinylidene fluoride) membranes: Roles of additives and their cumulative effects. J Membr Sci 619:118773

Ahmad T, Guria C, Mandal A (2020) A review of oily wastewater treatment using ultrafiltration membrane: a parametric study to enhance the membrane performance. J Water Process Eng 36:101289

Mei S, Xiao C, Hu X (2011) Preparation of porous PVC membrane via a phase inversion method from PVC/DMAc/water/additives. J Appl Polym Sci 120:557–562

Cui Y, Yao Z-K, Zheng K, Du S-Y, Zhu B-K, Zhu L-P, Du C-H (2015) Positively-charged nanofiltration membrane formed by quaternization and cross-linking of blend PVC/P (DMA-co-MMA) precursors. J Membr Sci 492:187–196

Fan X, Su Y, Zhao X, Li Y, Zhang R, Zhao J, Jiang Z, Zhu J, Ma Y, Liu Y (2014) Fabrication of polyvinyl chloride ultrafiltration membranes with stable antifouling property by exploring the pore formation and surface modification capabilities of polyvinyl formal. J Membr Sci 464:100–109

Xie Y-X, Wang K-K, Yu W-H, Cui M-B, Shen Y-J, Wang X-Y, Fang L-F, Zhu B-K (2020) Improved permeability and antifouling properties of polyvinyl chloride ultrafiltration membrane via blending sulfonated polysulfone. J Colloid Interface Sci 579:562–572

Su Y, Zhao Q, Liu J, Zhao J, Li Y, Jiang Z (2015) Improved oil/water emulsion separation performance of PVC/CPVC blend ultrafiltration membranes by fluorination treatment. Desalin Water Treat 55:304–314

Nasrollahi N, Vatanpour V, Aber S (2019) Improving the permeability and antifouling property of PES ultrafiltration membranes using the drying method and incorporating the CuO-ZnO nanocomposite. J Water Process Eng 31:100891

Hoseinpour S, Jafarzadeh Y, Yegani R, Masoumi S (2019) Embedding neat and carboxylated nanodiamonds into polypropylene membranes to enhance antifouling properties. Polyolefins J 6:63–74

Behboudi A, Jafarzadeh Y, Yegani R (2017) Polyvinyl chloride/polycarbonate blend ultrafiltration membranes for water treatment. J Membr Sci 534:18–24

Kazerouni HN, Jafarzadeh Y, Yegani R (2020) Study on the effect of m-phenylenediamine as a cross-linking agent on the mechanical, chemical and thermal properties and performance of cellulose acetate/nanodiamond membranes. Polym Bull 77:405–425

Mahlangu O, Nackaerts R, Thwala J, Mamba B, Verliefde A (2017) Hydrophilic fouling-resistant GO-ZnO/PES membranes for wastewater reclamation. J Membr Sci 524:43–55

Haghighat N, Vatanpour V, Sheydaei M, Nikjavan Z (2020) Preparation of a novel polyvinyl chloride (PVC) ultrafiltration membrane modified with Ag/TiO2 nanoparticle with enhanced hydrophilicity and antibacterial activities. Sep Purif Technol 237:116374

El-Gendi A, Abdallah H, Amin A, Amin SK (2017) Investigation of polyvinylchloride and cellulose acetate blend membranes for desalination. J Mol Struct 1146:14–22

Peng Y, Sui Y (2006) Compatibility research on PVC/PVB blended membranes. Desalination 196:13–21

Ali U, Karim KJBA, Buang NA (2015) A review of the properties and applications of poly (methyl methacrylate)(PMMA). Polym Rev 55:678–705

Mohammed G, El Sayed AM, El-Gamal S (2020) Effect of M nitrates on the optical, dielectric relaxation and porosity of PVC/PMMA membranes (M= Cd Co, Cr or Mg). J Inorg Organomet Polym Mater 30:1306–1319

Ochoa N, Masuelli M, Marchese J (2003) Effect of hydrophilicity on fouling of an emulsified oil wastewater with PVDF/PMMA membranes. J Membr Sci 226:203–211

Fang L-F, Zhu B-K, Zhu L-P, Matsuyama H, Zhao S (2017) Structures and antifouling properties of polyvinyl chloride/poly (methyl methacrylate)-graft-poly (ethylene glycol) blend membranes formed in different coagulation media. J Membr Sci 524:235–244

Schouten A, Challa G (1974) Bulk polymerization of methyl methacrylate in the presence of poly(methyl methacrylate). II. Effect of oxygen. J Polym Sci Polym Chem Ed 12:2145–2147

Rahimi A, Mahdavi H (2019) Zwitterionic-functionalized GO/PVDF nanocomposite membranes with improved anti-fouling properties. J Water Process Eng 32:100960

Sivakumar M, Mohanasundaram A, Mohan D, Balu K, Rangarajan R (1998) Modification of cellulose acetate: its characterization and application as an ultrafiltration membrane. J Appl Polym Sci 67:1939–1946

Beygmohammdi F, Kazerouni HN, Jafarzadeh Y, Hazrati H, Yegani R (2020) Preparation and characterization of PVDF/PVP-GO membranes to be used in MBR system. Chem Eng Res Des 154:232–240

Jafarzadeh Y, Yegani R (2015) Analysis of fouling mechanisms in TiO2 embedded high density polyethylene membranes for collagen separation. Chem Eng Res Des 93:684–695

Javadi M, Jafarzadeh Y, Yegani R, Kazemi S (2018) PVDF membranes embedded with PVP functionalized nanodiamond for pharmaceutical wastewater treatment. Chem Eng Res Des 140:241–250

Jafarzadeh Y, Yegani R, Sedaghat M (2015) Preparation, characterization and fouling analysis of ZnO/polyethylene hybrid membranes for collagen separation. Chem Eng Res Des 94:417–427

Akbari A, Yegani R, Pourabbas B, Behboudi A (2016) Fabrication and study of fouling characteristics of HDPE/PEG grafted silica nanoparticles composite membrane for filtration of Humic acid. Chem Eng Res Des 109:282–296

Behboudi A, Jafarzadeh Y, Yegani R (2016) Preparation and characterization of TiO2 embedded PVC ultrafiltration membranes. Chem Eng Res Des 114:96–107

Demirel E, Zhang B, Papakyriakou M, Xia S, Chen Y (2017) Fe2O3 nanocomposite PVC membrane with enhanced properties and separation performance. J Membr Sci 529:170–184

Bourlinos AB, Gournis D, Petridis D, Szabó T, Szeri A, Dékány I (2003) Graphite oxide: chemical reduction to graphite and surface modification with primary aliphatic amines and amino acids. Langmuir 19:6050–6055

Deriszadeh A, Shahraki F, Kalhori DM, Jazani OM (2019) Epoxy/GO nanocomposite adhesives reinforced with waste blends of PET/GTR: evaluation of mechanical properties. Prog Org Coat 136:105292

Kivi MA, Alinia H, Jafarzadeh Y, Yegani R (2019) High-density polyethylene membranes embedded with carboxylated and polyethylene glycol-grafted nanodiamond to be used in membrane bioreactors. J Appl Polym Sci 136:47914

Pagidi A, Saranya R, Arthanareeswaran G, Ismail A, Matsuura T (2014) Enhanced oil–water separation using polysulfone membranes modified with polymeric additives. Desalination 344:280–288

Feldman K, Tervoort T, Smith P, Spencer ND (1998) Toward a force spectroscopy of polymer surfaces. Langmuir 14:372–378

Younas H, Zhou Y, Li X, Li X, Sun Q, Cui Z, Wang Z (2019) Fabrication of high flux and fouling resistant membrane: a unique hydrophilic blend of polyvinylidene fluoride/polyethylene glycol/polymethyl methacrylate. Polymer 179:121593

Younas H, Shao J, Bai H, Liu L, He Y (2016) Inherent porous structure modified by titanium dioxide nanoparticle incorporation and effect on the fouling behavior of hybrid poly (vinylidene fluoride) membranes. J Appl Polym Sci 133

Sun H, Zhang Y, Sadam H, Ma J, Bai Y, Shen X, Kim J-K, Shao L (2019) Novel mussel-inspired zwitterionic hydrophilic polymer to boost membrane water-treatment performance. J Membr Sci 582:1–8

Johari A, Razmjouei M, Mansourizadeh A, Emadzadeh D (2020) Fabrication of blend hydrophilic polyamide imide (Torlon®)-sulfonated poly (ether ether ketone) hollow fiber membranes for oily wastewater treatment. Polym Test 91:106733

Wu H, Tang B, Wu P (2014) Development of novel SiO2–GO nanohybrid/polysulfone membrane with enhanced performance. J Membr Sci 451:94–102

Abdallah H, Taman R, Elgayar D, Farag H (2018) Antibacterial blend polyvinylidene fluoride/polyethyleneimine membranes for salty oil emulsion separation. Eur Polym J 108:542–553

Nawi NIM, Sait NR, Bilad MR, Shamsuddin N, Jaafar J, Nordin NAH, Narkkun T, Faungnawakij K, Mohshim DF (2021) Polyvinylidene fluoride membrane via vapour induced phase separation for oil/water emulsion filtration. Polymers 13:427

Paquin F, Rivnay J, Salleo A, Stingelin N, Silva C (2013) Multi-phase semicrystalline microstructures drive exciton dissociation in neat plastic semiconductors, arXiv preprint arXiv:1310.8002

Paquin F, Rivnay J, Salleo A, Stingelin N, Silva-Acuña C (2015) Multi-phase microstructures drive exciton dissociation in neat semicrystalline polymeric semiconductors. J Mater Chem C 3:10715–10722

Rashidi R, Khakpour S, Masoumi S, Jafarzadeh Y (2021) Effects of GO-PEG on the performance and structure of PVC ultrafiltration membranes. Chem Eng Res Des

Billmeyer FW (1984) Textbook of polymer science. Wiley, London

Acknowledgements

The authors would like to thank the support from the Iran National Science Foundation (INSF) under Grant Number 97017736.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Omidvar, A., Masoumi, S., Monsefi, M. et al. PVC/PMMA blend ultrafiltration membranes for oil-in-water emulsion separation. Polym. Bull. 80, 9275–9295 (2023). https://doi.org/10.1007/s00289-022-04514-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-022-04514-6