Abstract

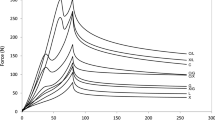

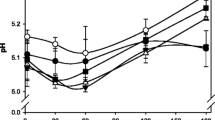

Mechanical and textural properties of processed cheeses are affected by low-fat, and hydrocolloids are commonly used as fat mimetics due their ability to make connections with water molecules. The aim of this study was to evaluate the stabilizing effect of Acacia mearnsii gum in low-fat processed cheeses, through physicochemical, composition, rheological and texture analyses. Processed cheeses were made with a 50% fat reduction and added with 0.125, 0.250, 0.375 and 0.5% (w/v) of A. mearnsii gum (AMS), and also were prepared samples full-fat (standard sample) and low-fat without gum (control sample). The chemical composition, physicochemical, textural and viscoelastic properties of processed cheeses were analyzed. Samples with A. mearnsii gum showed a higher amount of carbohydrates and protein content similar to the standard sample. The low-fat content influenced the rheological and textural properties of the processed cheeses, and they had liquid-like behavior and were softer and more spreadable. Processed low-fat cheese with a higher AMS concentration showed viscoelastic behavior similar to the full-fat sample. With standard sample exception, all other processed cheeses when subjected to temperature variation cycles (thermoreversibility test) showed identical behavior, without changes in viscoelastic behavior, being characterized as thermostable systems. AMS addition promoted the molecular interactions (increased cohesiveness) between the formulation constituents. The results showed that A. mearnsii gum has stabilizing potential for the food processing, being able to stabilize products with low-fat content.

Similar content being viewed by others

References

Van Dender AGF (2014) Requeijao cremoso and other processed cheeses: manufacturing technology, process control and market aspects, 2nd edn. Setembro Editora, São Paulo

da Silva DF, de Souza Ferreira SB, Bruschi ML et al (2016) Effect of commercial konjac glucomannan and konjac flours on textural, rheological and microstructural properties of low fat processed cheese. Food Hydrocoll 60:308–316. https://doi.org/10.1016/j.foodhyd.2016.03.034

Kapoor R, Metzger LE (2008) Process cheese: scientific and technological aspects—a review. Compr Rev Food Sci Food Saf 7:194–214. https://doi.org/10.1111/j.1541-4337.2008.00040.x

Ferrão LL, Silva EB, Silva HLA et al (2016) Strategies to develop healthier processed cheeses: reduction of sodium and fat contents and use of prebiotics. Food Res Int 86:93–102. https://doi.org/10.1016/j.foodres.2016.04.034

Johnson ME, Kapoor R, McMahon DJ et al (2009) Reduction of sodium and fat levels in natural and processed cheeses: scientific and technological aspects. Compr Rev Food Sci Food Saf 8:252–268. https://doi.org/10.1111/j.1541-4337.2009.00080.x

Černíková M, Nebesářová J, Salek RN et al (2017) Microstructure and textural and viscoelastic properties of model processed cheese with different dry matter and fat in dry matter content. J Dairy Sci 100:4300–4307. https://doi.org/10.3168/jds.2016-12120

Brummel SE, Lee K (1990) Soluble hydrocolloids enable fat reduction in process cheese spreads. J Food Sci 55:1290–1292. https://doi.org/10.1111/j.1365-2621.1990.tb03918.x

Swenson BJ, Wendorff WL, Lindsay RC (2000) Effects of ingredients on the functionality of fat-free process cheese spreads. J Food Sci 65:822–825. https://doi.org/10.1111/j.1365-2621.2000.tb13594.x

Kommineni A, Amamcharla J, Metzger LE (2012) Effect of xylitol on the functional properties of low-fat process cheese. J Dairy Sci 95:6252–6259. https://doi.org/10.3168/jds.2012-5376

El-Assar MA, Abou-Dawoo SA, Sakr SS, Younis NM (2018) Low-fat processed cheese spread with added inulin: its physicochemical, rheological and sensory characteristics. Int J Dairy Sci 14:12–20. https://doi.org/10.3923/ijds.2019.12.20

Saraiva BR, Licci NM, Anjo FA et al (2020) Effects of inulin and canistel addition in the physical characteristics of fat-reduced processed cheese. Res Soc Dev 9:e4289119917. https://doi.org/10.33448/rsd-v9i11.9917

Aspinall GO, Carlyle JJ, Young R (1968) Acacia mearnsii gum. Carbohydr Res 7:421–430. https://doi.org/10.1016/S0008-6215(00)82961-4

Grein-Iankovski A, Ferreira JGL, Orth ES et al (2018) A comprehensive study of the relation between structural and physical chemical properties of acacia gums. Food Hydrocoll 85:167–175. https://doi.org/10.1016/j.foodhyd.2018.07.011

Grein-Iankovski A, Riegel-Vidotti IC, Simas-Tosin FF et al (2016) Exploring the relationship between nanoscale dynamics and macroscopic rheology in natural polymer gums. Soft Matter 12:9321–9329. https://doi.org/10.1039/c6sm01492e

Grein A, da Silva BC, Wendel CF et al (2013) Structural characterization and emulsifying properties of polysaccharides of Acacia mearnsii de Wild gum. Carbohydr Polym 92:312–320. https://doi.org/10.1016/j.carbpol.2012.09.041

da Silva BC, da Oliveira M, Ferreira JGL et al (2015) Polyelectrolyte complexes from gum arabic and gelatin: optimal complexation pH as a key parameter to obtain reproducible microcapsules. Food Hydrocoll 46:201–207. https://doi.org/10.1016/j.foodhyd.2014.12.022

Anjo FA, Saraiva BR, da Silva JB et al (2021) Acacia mearnsii gum: a residue as an alternative gum Arabic for food stabilizer. Food Chem 344:128640. https://doi.org/10.1016/j.foodchem.2020.128640

AOAC (1990) Official Methods of Analysis of AOAC International. In: Association of Official Analysis Chemists International. pp 1058–1059

Balthazar CF, Silva HLA, Vieira AH et al (2017) Assessing the effects of different prebiotic dietary oligosaccharides in sheep milk ice cream. Food Res Int. https://doi.org/10.1016/j.foodres.2016.11.008

Pathare PB, Opara UL, Al-Said FA-J (2013) Colour measurement and analysis in fresh and processed foods: a review. Food Bioproc Tech 6:36–60. https://doi.org/10.1007/s11947-012-0867-9

Bashir M, Haripriya S (2016) Assessment of physical and structural characteristics of almond gum. Int J Biol Macromol 93:476–482. https://doi.org/10.1016/j.ijbiomac.2016.09.009

Daoub RMA, Elmubarak AH, Misran M et al (2018) Characterization and functional properties of some natural Acacia gums. J Saudi Soc Agric Sci 17:241–249. https://doi.org/10.1016/j.jssas.2016.05.002

Venkatesham M, Ayodhya D, Madhusudhan A, Veerabhadram G (2012) Synthesis of stable silver nanoparticles using gum acacia as reducing and stabilizing agent and study of its microbial properties: a novel green approach. Int J Green Nanotechnol 4:199–206. https://doi.org/10.1080/19430892.2012.705999

Tischer C, Gorin PAJ, Iacomini M (2002) The free reducing oligosaccharides of gum arabic: aids for structural assignments in the polysaccharide. Carbohydr Polym 47:151–158. https://doi.org/10.1016/S0144-8617(01)00173-4

Petkowicz CLO, Sierakowski M-R, Ganter JLMS, Reicher F (1998) Galactomannans and arabinans from seeds of caesalpiniaceae. Phytochemistry 49:737–743. https://doi.org/10.1016/S0031-9422(98)00228-3

Delgobo CL, Gorin PAJ, Tischer CA, Iacomini M (1999) The free reducing oligosaccharides of angico branco (Anadenanthera colubrina) gum exudate: an aid for structural assignments in the heteropolysaccharide. Carbohydr Res 320:167–175. https://doi.org/10.1016/S0008-6215(99)00159-7

Lopez-Torrez L, Nigen M, Williams P et al (2015) Acacia senegal vs. Acacia seyal gums—Part 1: composition and structure of hyperbranched plant exudates. Food Hydrocoll 51:41–53. https://doi.org/10.1016/J.FOODHYD.2015.04.019

Barth A, Zscherp C (2002) What vibrations tell about proteins. Q Rev Biophys 35:369–430. https://doi.org/10.1017/S0033583502003815

Sene CFB, McCann MC, Wilson RH, Grinter R (1994) Fourier-Transform Raman and Fourier-Transform Infrared Spectroscopy (an investigation of five higher plant cell walls and their components). Plant Physiol 106:1623–1631. https://doi.org/10.1104/PP.106.4.1623

Barth A (2007) Infrared spectroscopy of proteins. Biochimica et Biophysica Acta (BBA) - Bioenergetics 1767:1073–1101. https://doi.org/10.1016/J.BBABIO.2007.06.004

Synytsya A, Čopíková J, Matějka P, Machovič V (2003) Fourier transform Raman and infrared spectroscopy of pectins. Carbohydr Polym 54:97–106. https://doi.org/10.1016/S0144-8617(03)00158-9

Wadhwani R, McMahon DJ (2012) Color of low-fat cheese influences flavor perception and consumer liking. J Dairy Sci 95:2336–2346. https://doi.org/10.3168/jds.2011-5142

Slots T, Butler G, Leifert C et al (2009) Potentials to differentiate milk composition by different feeding strategies. J Dairy Sci 92:2057–2066. https://doi.org/10.3168/jds.2008-1392

Liu H, Xu XM, Guo SD (2008) Comparison of full-fat and low-fat cheese analogues with or without pectin gel through microstructure, texture, rheology, thermal and sensory analysis. Int J Food Sci Technol 43:1581–1592. https://doi.org/10.1111/J.1365-2621.2007.01616.X

Schramm G (2006) Reologia e reometria: fundamentos teóricos e práticos. Artliber, São Paulo

Belsito PC, Ferreira MVS, Cappato LP et al (2017) Manufacture of Requeijão cremoso processed cheese with galactooligosaccharide. Carbohydr Polym 174:869–875. https://doi.org/10.1016/j.carbpol.2017.07.021

Lee SK, Klostermeyer H (2001) The effect of pH on the rheological properties of reduced-fat model processed cheese spreads. LWT Food Sci Technol 34:288–292. https://doi.org/10.1006/FSTL.2001.0761

Rønholt S, Kirkensgaard JJK, Pedersen TB et al (2012) Polymorphism, microstructure and rheology of butter. Effects of cream heat treatment. Food Chem 135:1730–1739. https://doi.org/10.1016/j.foodchem.2012.05.087

Wright AJ, Scanlon MG, Hartel RW, Marangoni AG (2001) Rheological properties of milkfat and butter. J Food Sci 66:1056–1071. https://doi.org/10.1111/j.1365-2621.2001.tb16082.x

Hennelly PJ, Dunne PG, O’Sullivan M, O’Riordan ED (2006) Textural, rheological and microstructural properties of imitation cheese containing inulin. J Food Eng 75:388–395. https://doi.org/10.1016/j.jfoodeng.2005.04.023

Solhi P, Azadmard-Damirchi S, Hesari J, Hamishehkar H (2020) Production of the processed cheese containing tomato powder and evaluation of its rheological, chemical and sensory characteristics. J Food Sci Technol 57:2198–2205. https://doi.org/10.1007/s13197-020-04256-1

Hanáková Z, Buňka F, Pavlínek V et al (2013) The effect of selected hydrocolloids on the rheological properties of processed cheese analogues made with vegetable fats during the cooling phase. Int J Dairy Technol 66:484–489. https://doi.org/10.1111/1471-0307.12066

Prentice JH (1972) Rheology and texture of dairy products. J Texture Stud 3:415–458. https://doi.org/10.1111/J.1745-4603.1972.TB00643.X

Thevenet F (2009) Acacia Gum (Gum Arabic). In: Food stabilisers, thickeners and gelling agents, pp 11–30. https://doi.org/10.1002/9781444314724.CH2

Elmanan M, Al-Assaf S, GlynO P, PeterA W (2008) Studies on Acacia exudate gums: Part VI. Interfacial rheology of Acacia senegal and Acacia seyal. Food Hydrocoll 22:682–689. https://doi.org/10.1016/j.foodhyd.2007.02.008

Acknowledgements

We thank the Coordination for the Improvement of High Education Personnel (CAPES) by scholarship and SETA Company (Rio Grande do Sul, Brazil) by collecting and sending samples of crude A. mearnsii gum exudate.

Author information

Authors and Affiliations

Contributions

Conceptualization: FAA, ICR-V, FFS, and PTM-P; methodology: FAA, MLB, FS, FFS, and PTM-P; formal analysis and investigation: FAA, BRS, JBS, and CYLO; writing—original draft preparation: FAA; writing—review and editing: FAA; MLB, FFS, FS, and PTM-P; funding acquisition:: FAA; MLB, FS, FFS, and PTM-P; resources: FAA; MLB, FS, ICR-V, FFS, and PTM-P; supervision: MLB, FFS, FS, ICR-V, and PTM-P.

Corresponding author

Ethics declarations

Conflict of interest

The authors have declared no conflicts of interest for this article.

Ethical approval

This article does not contain any studies with human or animal subjects.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Anjo, F.A., Saraiva, B.R., da Silva, J.B. et al. A new food stabilizer in technological properties of low-fat processed cheese. Eur Food Res Technol 249, 597–606 (2023). https://doi.org/10.1007/s00217-022-04155-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-022-04155-z