Abstract

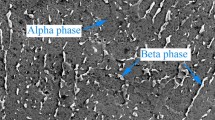

The formability and microstructure of TC4 titanium alloy hollow shafts formed by cross-wedge rolling (CWR) are being investigated to ensure that products manufactured for utilisation in the aviation sector are lightweight. The flow behaviour of the TC4 alloy was studied via isothermal hot compression tests. The constitutive equations in different phase regions were then established and applied to a finite element (FE) model to study the effect of process parameters on the ellipticity of the TC4 alloy hollow shafts formed by CWR. Corresponding CWR experiments were conducted to validate the FE model; further, the microstructure of the TC4 alloy hollow shafts was investigated. The results demonstrate that forming angle, stretching angle and area reduction considerably affect the ellipticity of the TC4 alloy hollow shafts by varying the contact area between a die and a workpiece. The ellipticity evidently increases as the relative wall thickness decreases, as the flattening deformation increases. An increase in the deformation temperature will result in a decrease in the deformation resistance of the TC4 alloy and an increase in the ellipticity. Moreover, the effect of the deformation temperature, area reduction and wall thickness of the workpiece on the microstructure of the TC4 alloy hollow shafts formed by CWR was investigated. The degree of kink or globularisation of the strip alpha phase increases with the above parameters. The volume fraction of the beta phase increases with the deformation temperature. The microstructure is typically equiaxed when the deformation temperature is 950 °C.

Similar content being viewed by others

Data availability

The datasets generated and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Boyer RR (1995) Titanium for aerospace: rationale and applications. Adv Perform Mater 2:349–368. https://doi.org/10.1007/BF00705316

Li MQ, Li H, Luo J (2016) Precision forging of titanium alloy. Science Press, Beijing (in Chinese)

Hu ZH, Zhang KS, Wang BY, Zhang W (1996) Theory and application of cross wedge rolling. Metallurgical Industry Press, Beijing (In Chinese)

Bartnicki J, Pater Z (2004) The aspects of stability in cross-wedge rolling processes of hollow shafts. J Mater Process Technol 155-156:1867–1873. https://doi.org/10.1016/j.jmatprotec.2004.04.278

Bartnicki J, Pater Z (2005) Numerical simulation of three-rolls cross-wedge rolling of hollow shaft. J Mater Process Technol 164-165:1154–1159. https://doi.org/10.1016/j.jmatprotec.2005.02.120

Ding W, Zhang KS, Yang CP, Hu ZH (2010) Study on the ovality of hollow shafts with equal inner diameter formed by cross wedge rolling. J Plast Eng 17:27–31. (in Chinese). https://doi.org/10.3969/j.issn.1007-2012.2010.03.006

Yang CP, Hu ZH (2014) Influence of flattening deformation on the forming of hollow parts in cross-wedge rolling. Trans Beijing Inst Technol 34:881–885 (in Chinese)

Yang CP, Hu ZH (2015) Research on the ovality of hollow shafts in cross wedge rolling with mandrel. Int J Adv Manuf Technol 83:67–76. https://doi.org/10.1007/s00170-015-7478-3

Ji HC, Liu JP, Wang BY, Zheng ZH, Huang JH, Hu ZH (2015) Cross wedge rolling of a 4Cr9Si2 hollow valve: explorative experiment and finite element simulation. Int J Adv Manuf Technol 77:15–26. https://doi.org/10.1007/s00170-014-6363-9

Ji HC, Liu JP, Wang BY, Fu XB, Xiao WC, Hu ZH (2017) A new method for manufacturing hollow valves via cross wedge rolling and forging: Numerical analysis and experiment validation. J Mater Process Technol 240:1–11. https://doi.org/10.1016/j.jmatprotec.2016.09.004

Huang X, Wang BY, Mu YH, Shen JX, Li JL, Zhou J (2019) Investigation on the effect of mandrels on hollow shafts in cross-wedge rolling. Int J Adv Manuf Technol 102:443–455. https://doi.org/10.1007/s00170-018-3093-4

Urankar S, Lovell M, Morrow C, Li Q, Kawada K (2006) Establishment of failure conditions for the cross-wedge rolling of hollow shafts. J Mater Process Technol 177:545–549. https://doi.org/10.1016/j.jmatprotec.2006.04.052

Urankar S, Lovell M, Morrow C, Li Q, Kawada K (2006) Development of a critical friction model for cross wedge rolling hollow shafts. J Mater Process Technol 177(1–3):539–544. https://doi.org/10.1016/j.jmatprotec.2006.04.048

Çakırcalı M, Kılıçaslan C, Güden M, Kıranlı E, Shchukin VY, Petronko VV (2013) Cross wedge rolling of a Ti6Al4V (ELI) alloy: the experimental studies and the finite element simulation of the deformation and failure. Int J Adv Manuf Technol 65:1273–1287. https://doi.org/10.1007/s00170-012-4256-3

Li JL, Wang BY, Ji HC, Huang X, Tang XF, Ma WP (2017) Effects of the cross-wedge rolling parameters on the formability of Ti-6Al-4V alloy. Int J Adv Manuf Technol 92:2217–2229. https://doi.org/10.1007/s00170-017-0263-8

Li JL, Wang BY, Ji HC, Zhou J, Fu XB, Huang X (2018) Numerical and experimental investigation on the cross wedge rolling of powder sintering TC4 alloy. Int J Adv Manuf Technol 94:2149–2162. https://doi.org/10.1007/s00170-017-0992-8

Li JL, Wang BY, Qin Y, Fang S, Huang X, Chen P (2019) Investigating the effects of process parameters on the cross wedge rolling of TC6 titanium alloy based on temperature and strain rate sensitivities. Int J Adv Manuf Technol 103:2563–2577. https://doi.org/10.1007/s00170-019-03461-3

Zhao YQ, Chen YN, Zhang XM, Zeng XD, Wang L (2012) Phase transformation and heat treatment of titanium alloys. Central South University Press, Changsha (in Chinese)

Ding R, Guo ZX, Wilson A (2002) Microstructural evolution of a Ti-6Al-4V alloy during thermomechanical processing. Mater Sci Eng A 327:233–245. https://doi.org/10.1016/S0921-5093(01)01531-3

Bai Q, Lin JG, Dean TA, Balint DS, Gao T, Zhang Z (2013) Modelling of dominant softening mechanisms for Ti-6Al-4V in steady state hot forming conditions. Mater Sci Eng A 559:352–358. https://doi.org/10.1016/j.msea.2012.08.110

Miller RM, Bieler TR, Semiatin SL (1999) Flow softening during hot working of Ti-6Al-4V with a lamellar colony micro-structure. Scr Mater 40:1387–1393. https://doi.org/10.1016/S1359-6462(99)00061-5

Semiatin SL, Seetharaman V, Weiss I (1999) Flow behavior and globularization kinetics during hot working of Ti–6Al–4V with a colony alpha microstructure. Mater Sci Eng 263:257–271. https://doi.org/10.1016/S0921-5093(98)01156-3

Acknowledgements

This work is supported by the Aeronautical Science Foundation of China (Grant No. 20173674003), the National Natural Science Foundation of China (Grant No. 51875036), and the Engineering Research Center of Part Near-Net-Shape forming of Ministry of Education.

Author information

Authors and Affiliations

Contributions

Pengni Feng: conceptualization, investigation, methodology, data curation, writing–original draft, reviewing and editing.

Cuiping Yang: supervision, conceptualization, methodology, resources, funding acquisition, reviewing and editing.

Baoyu Wang: supervision, conceptualization, methodology, funding acquisition, reviewing and editing.

Junling Li: supervision, methodology, reviewing and editing.

Jinxia Shen: supervision, methodology, reviewing and editing.

Xiaoming Yang: supervision, reviewing and editing.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The article follows the guidelines of the Committee on Publication Ethics (COPE) and involves no studies on human or animal subjects.

Consent for publication

Applicable.

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Feng, P., Yang, C., Wang, B. et al. Formability and microstructure of TC4 titanium alloy hollow shafts formed by cross-wedge rolling with a mandrel. Int J Adv Manuf Technol 114, 365–377 (2021). https://doi.org/10.1007/s00170-021-06635-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-06635-0