Abstract

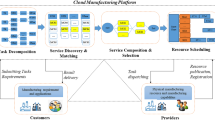

In modern manufacturing industry, resource efficiency is negatively affected by the high fluctuations of demands within the global market. In this work, an intelligent cloud manufacturing platform is proposed to increase resource efficiency, productivity, and utilization rates in a smart manufacturing network by dynamically matching manufacturing services offers and requests through the broad sharing and on-demand delivery of distributed computational, software, digital, and physical manufacturing resources. The cloud platform is developed with particular reference to the sheet metal cutting sector and includes several modules. A database module is employed for users data input and storage. An intelligent assessment and optimization module performs the functional and geometrical assessments of the sheet metal cutting instances entered by customers and suppliers and makes use of a genetic algorithm to optimize the manufacturing solutions with specific attention to the surface utilization rate, as key performance index of resource efficiency. A decision-making module supports the supplier in the selection of the best production strategy and the customer in the evaluation and comparison of the best manufacturing solutions ranked according to the preferred criteria. To demonstrate the implementation of the proposed cloud manufacturing platform in a manufacturing network scenario, a case study including several customer and supplier instances is presented, showing the multiple manufacturing solutions proposed by the platform and the advantages in terms of industrial resource efficiency improvement.

Similar content being viewed by others

References

Verlinden B, Cattrysse D, Van Oudheusden D (2007) Integrated sheet-metal production planning for laser cutting and bending. Int J Prod Res 45:369–383. https://doi.org/10.1080/00207540600658062

Dallan A Sheet metal working: where is 15,9% of raw material being wasted? Available online: https://www.linkedin.com/pulse/sheet-metal-working-where-159-raw-material-being-wasted-andrea-dallan/ (accessed on Oct 5, 2018)

Zhang L, Luo Y, Tao F, Li BH, Ren L, Zhang X, Guo H, Cheng Y, Hu A, Liu Y (2014) Cloud manufacturing: a new manufacturing paradigm. Enterp Inf Syst 8:167–187. https://doi.org/10.1080/17517575.2012.683812

Xu X (2012) From cloud computing to cloud manufacturing. Robot Comput Integr Manuf 28:75–86. https://doi.org/10.1016/j.rcim.2011.07.002

Li F, Liao TW, Zhang L (2019) Two-level multi-task scheduling in a cloud manufacturing environment. Robot Comput Integr Manuf 56:127–139. https://doi.org/10.1016/j.rcim.2018.09.002

Simeone A, Caggiano A, Deng B, Zeng Y, Boun L (2018) Resource efficiency optimization engine in smart production networks via intelligent cloud manufacturing platforms. Procedia CIRP 78:19–24. https://doi.org/10.1016/j.procir.2018.10.003

Simeone A, Caggiano A, Boun L, Deng B (2019) Intelligent cloud manufacturing platform for efficient resource sharing in smart manufacturing networks. Procedia CIRP 79:233–238. https://doi.org/10.1016/j.procir.2019.02.056

Wu D, Rosen DW, Schaefer D (2015) Scalability planning for cloud-based manufacturing systems. J Manuf Sci Eng 137:040911. https://doi.org/10.1115/1.4030266

Caggiano A, Segreto T, Teti R (2016) Cloud manufacturing framework for smart monitoring of machining. Procedia CIRP 55:248–253. https://doi.org/10.1016/j.procir.2016.08.049

Caggiano A (2018) Cloud-based manufacturing process monitoring for smart diagnosis services. Int J Comput Integr Manuf. https://doi.org/10.1080/0951192X.2018.1425552

Sakaguchi T, Tanaka T, Shimizu Y, Uchiyama N 2016 International symposium on flexible automation a scheduling method using genetic algorithm and dispatching rule 2016, 1–3

Pan M, Rao Y (2009) An integrated knowledge based system for sheet metal cutting-punching combination processing. Knowl Based Syst 22:368–375. https://doi.org/10.1016/j.knosys.2009.02.008

de Carvalho JMV (2002) LP models for bin packing and cutting stock problems. Eur J Oper Res 141:253–273

Herrmann JW, Delalio DR (2001) Algorithms for sheet metal nesting. IEEE Trans Robot Autom 17:183–190. https://doi.org/10.1109/70.928563

Anand KV, Babu AR (2015) Computers & industrial engineering heuristic and genetic approach for nesting of two-dimensional rectangular shaped parts with common cutting edge concept for laser cutting and profile blanking processes. Comput Ind Eng 80:111–124. https://doi.org/10.1016/j.cie.2014.11.018

Sakaguchi T, Matsumoto K, Uchiyama N 2018 Nesting scheduling in sheet metal processing based on coevolutionary genetic algorithm in different environments, 12

Cheng Y, Bi L, Tao F, Ji P (2018) Hypernetwork-based manufacturing service scheduling for distributed and collaborative manufacturing operations towards smart manufacturing. J Intell Manuf:1–14. https://doi.org/10.1007/s10845-018-1417-8

Liu Y, Wang L, Wang XV, Xu X, Zhang L (2018) Scheduling in cloud manufacturing : state-of-the- art and research challenges. Int J Prod Res 7543:1–26. https://doi.org/10.1080/00207543.2018.1449978

Tao F, Zhang L, Venkatesh VC, Luo Y, Cheng Y (2011) Cloud manufacturing: a computing and service- oriented manufacturing model. Proc Inst Mech Eng Part B J Eng Manuf 225:1969–1976. https://doi.org/10.1177/0954405411405575

Cao Y, Wang S, Kang L, Gao Y (2016) A TQCS-based service selection and scheduling strategy in cloud manufacturing:235–251. https://doi.org/10.1007/s00170-015-7350-5

Tao F, Cheng J, Cheng Y, Gu S, Zheng T, Yang H (2017) SDMSim: a manufacturing service supply–demand matching simulator under cloud environment. Robot Comput Integr Manuf. https://doi.org/10.1016/j.rcim.2016.07.001

Caggiano A, Segreto T, Teti R (2018) Cloud manufacturing on-demand services for holistic quality assurance of manufactured components. Procedia CIRP 67:144–149. https://doi.org/10.1016/j.procir.2017.12.191

Helo P, Phuong D, Hao Y (2018) Cloud manufacturing – scheduling as a service for sheet metal manufacturing. Comput Oper Res. https://doi.org/10.1016/J.COR.2018.06.002

Tapoglou N, Mehnen J, Vlachou A, Doukas M, Milas N, Mourtzis D (2015) Cloud-based platform for optimal machining parameter selection based on function blocks and real-time monitoring. J Manuf Sci Eng 137:040909. https://doi.org/10.1115/1.4029806

Wang L (2013) Machine availability monitoring and machining process planning towards cloud manufacturing. CIRP J Manuf Sci Technol 6:263–273. https://doi.org/10.1016/j.cirpj.2013.07.001

Mourtzis D, Vlachou E, Xanthopoulos N, Givehchi M, Wang L (2016) Cloud-based adaptive process planning considering availability and capabilities of machine tools. J Manuf Syst 39:1–8. https://doi.org/10.1016/j.jmsy.2016.01.003

Ahmadov Y, Helo P (2018) A cloud based job sequencing with sequence-dependent setup for sheet metal manufacturing. Ann Oper Res 270:5–24. https://doi.org/10.1007/s10479-016-2304-3

Wang L, Guo S, Li X, Du B, Xu W (2018) Distributed manufacturing resource selection strategy in cloud manufacturing:3375–3388. https://doi.org/10.1007/s00170-016-9866-8

Liu Y, Xu X, Zhang L, Wang L, Zhong RY (2017) Robotics and computer – integrated manufacturing workload-based multi-task scheduling in cloud manufacturing. Robot Comput Integr Manuf 45:3–20. https://doi.org/10.1016/j.rcim.2016.09.008

Zhang Z, Zhang Y, Lu J, Xu X, Gao F, Xiao G 2018 CMfgIA : a cloud manufacturing application mode for industry alliance, 2967–2985

Valvo E 2017 Lo meta-heuristic algorithms for nesting problem of rectangular pieces. In Procedia Engineering

Wäscher G, Haußner H, Schumann H (2007) An improved typology of cutting and packing problems. Eur J Oper Res. https://doi.org/10.1016/j.ejor.2005.12.047

Malaguti E, Medina Durán R, Toth P (2014) Approaches to real world two-dimensional cutting problems. Omega 47:99–115. https://doi.org/10.1016/j.omega.2013.08.007

Zheng W, Ren P, Ge P, Qiu Y, Liu Z (2012) Hybrid heuristic algorithm for two-dimensional steel coil cutting problem. Comput Ind Eng. https://doi.org/10.1016/j.cie.2011.12.012

Tay FEH, Chong TY, Lee FC (2002) Pattern nesting on irregular-shaped stock using genetic algorithms. Eng Appl Artif Intell. https://doi.org/10.1016/S0952-1976(03)00009-5

Shalaby MA, Kashkoush M (2013) A particle swarm optimization algorithm for a 2-D irregular strip packing problem. Am J Oper Res. https://doi.org/10.4236/ajor.2013.32024

Bennell JA, Dowsland KA (1999) A tabu thresholding implementation for the irregular stock cutting problem. Int J Prod Res 37:4259–4275. https://doi.org/10.1080/002075499189763

Gomes AM, Oliveira JF (2006) Solving irregular strip packing problems by hybridising simulated annealing and linear programming. Eur J Oper Res. https://doi.org/10.1016/j.ejor.2004.09.008

Bennell JA, Dowsland KA (2003) Hybridising tabu search with optimisation techniques for irregular stock cutting. Manag Sci. https://doi.org/10.1287/mnsc.47.8.1160.10230

Hopper E, Turton BCH (2001) A review of the application of meta-heuristic algorithms to 2D strip packing problems. Artif Intell Rev. https://doi.org/10.1023/A:1012590107280

Burke E, Hellier R, Kendall G, Whitwell G (2006) A new bottom-left-fill heuristic algorithm for the two- dimensional irregular packing problem. Oper Res 54. https://doi.org/10.1287/opre.1060.0293

Lodi A, Martello S, Monaci M, Vigo D 2014 Two-dimensional bin packing problems. In Paradigms of Combinatorial Optimization; Wiley-Blackwell; pp. 107–129 ISBN 9781119005353

Adamowicz M, Albano A (1976) Nesting two-dimensional shapes in rectangular modules. Comput Des. https://doi.org/10.1016/0010-4485(76)90006-3

Cantú-Paz E, Goldberg DE 2003 Are Multiple Runs of Genetic Algorithms Better than One? In; Springer, Berlin, Heidelberg; pp. 801–812

China Southern Power Grid Co. Ltd China Southern Power Grid Available online: http://eng.csg.cn (accessed on Mar 1, 2019)

Baidu Maps ©

Google Maps ©

ChinaWutong © chinawutong.com Available online: http://www.chinawutong.com/ (accessed on Mar 1, 2019)

Burke EK, Hellier RSR, Kendall G, Whitwell G (2007) Complete and robust no-fit polygon generation for the irregular stock cutting problem. Eur J Oper Res. https://doi.org/10.1016/j.ejor.2006.03.011

Funding

The research results presented in this paper are based on the activities carried out in the framework of the project CLOUD MODE “CLOUD Manufacturing for On-Demand manufacturing sErvices” (000011--ALTRI_DR_3450_2016_RICERCA_ ATENEO-CAGGIANO) funded by the University of Naples Federico II within the “Programma per il finanziamento della ricerca di Ateneo” (2016-2019) and the Research Start-up Fund Subsidized Project of Shantou University, China, (No. NFT17004).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Simeone, A., Deng, B. & Caggiano, A. Resource efficiency enhancement in sheet metal cutting industrial networks through cloud manufacturing. Int J Adv Manuf Technol 107, 1345–1365 (2020). https://doi.org/10.1007/s00170-020-05083-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05083-6