Abstract

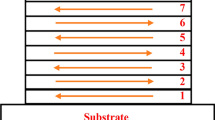

The process of deposition in metal additive manufacturing (AM) involves layer-by-layer stacking of material in a defined fashion. The temperature and temperature gradients involved during the deposition decides the final behaviour of the fabricated component. Hence, the temperature of the substrate over which the deposition is made is of equal importance as the temperature of the processing material during deposition. To consider this aspect, a design of heating bed on which the substrate is placed is explored through numerical simulation. In this direction, a thermal and fluid flow analysis for a heating bed is performed in the presented work by adopting the finite volume method (FVM). A 3D steady analysis is carried in ANSYS atmosphere. A heating bed with a specific configuration of cooling channels is simulated, and based on the uniformity of the thermal distribution, deposition region is identified. The presented work could find its probabilistic application in the additive manufacturing, wherein substrate heating is required for isothermal deposition of every layer, so as to ensure less residual stresses and reduced distortions in the final part.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Karunakaran, K.P., Suryakumar, S., Pushpa, V., Akula, S.: Low cost integration of additive and subtractive processes for hybrid layered manufacturing. Robot. Comput.-Integr. Manuf. 26(5), 490–499 (2010)

Sharma, G.K., Pant, P., Jain, P.K., Kankar, P.K. Tandon, P.: On the suitability of induction heating system for metal additive manufacturing. In: Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture (2020). https://doi.org/10.1177/0954405420937854

Jain, P.K., Pandey, P.M., Rao, P.V.M.: Experimental investigations for improving part strength in selective laser sintering. Virtual Phys. Prototyp. 3(3), 177–188 (2008)

Francis, V., Jain, P.K.: Effect of stage-dependent addition of nanoparticles in additive manufacturing. J. Thermoplast. Compos. Mater. 33(3), 357–376 (2020). https://doi.org/10.1177/0892705718805528

Fang, X., Du, J., Wei, Z., He, P., Bai, H., Wang, X., Lu, B.: An investigation on effects of process parameters in fused-coating based metal additive manufacturing. J. Manuf. Processes 28, 383–389 (2017)

Keşkekçi, A.B., Şenol, R., Bayrakci, H.C.: Fuzzy logic approach for warping problem in 3D printing. Int. J. Comput. Exp. Sci. Eng. 6(1), 75–77 (2020)

Shamsaei, N., Yadollahi, A., Bian, L., Thompson, S.M.: An overview of direct laser deposition for additive manufacturing; part II: mechanical behavior, process parameter optimization and control. Addit. Manuf. 8, 12–35 (2015)

Pant, P., Chatterjee, D., Samanta, S.K., Nandi, T., Lohar, A.K.: A bottom-up approach to experimentally investigate the deposition of austenitic stainless steel in laser direct metal deposition system. J. Braz. Soc. Mech. Sci. Eng. 42(2), 1–10 (2020)

Corbin, D.J., Nassar, A.R., Reutzel, E.W., Beese, A.M., Michaleris, P.: Effect of substrate thickness and preheating on the distortion of laser deposited Ti–6Al–4V. J. Manuf. Sci. Eng. 140(6), 061009(1–10) (2018)

Alimardani, M., Fallah, V., Khajepour, A., Toyserkani, E.: The effect of localized dynamic surface preheating in laser cladding of Stellite 1. Surf. Coat. Technol. 204, 3911–3919 (2010)

Bajpei, T., Chelladurai, H., Ansari, M.Z.: Mitigation of residual stresses and distortions in thin aluminium alloy GMAW plates using different heat sink models. J. Manuf. Processes 22, 199–210 (2016)

Jendrzejewski, R., Śliwiński, G., Krawczuk, M., Ostachowicz, W.: Temperature and stress fields induced during laser cladding. Comput. Struct. 82(7–8), 653–658 (2004)

Klingbeil, N.W., Beuth, J.L., Chin, R.K., Amon, C.H.: Residual stress-induced warping in direct metal solid freeform fabrication. Int. J. Mech. Sci. 44(1), 57–77 (2002)

Wang, D., Wang, X., Liu, Y., Chen, P., Liu, J.: A study on the heat dissipation and thermal environment of a novel heated bed. J. Build. Phys. 42(5), 629–651 (2019)

Mechanical Properties of Gray Irons, Cast Iron Science and Technology. In: Stefanescu, D.M. (ed.) ASM Handbook, vol. 1A, pp. 430–455. ASM International (2017). https://doi.org/10.31399/asm.hb.v01a.a0006344

Nayak, B.B., Chatterjee, D.: Convective heat transfer in slurry flow in a horizontal Y-shaped branch pipe. Powder Technol. 318, 46–61 (2017)

Argyropoulos, C.D., Markatos, N.C.: Recent advances on the numerical modelling of turbulent flows. Appl. Math. Model. 39(2), 693–732 (2015)

Rictor, A., Riley, B.: Optimization of a heated platform based on statistical annealing of critical design parameters in a 3D printing application. Procedia Comput. Sci. 83, 712–716 (2016)

Acknowledgements

The author would like to thanks DST/TDT/AMT, India, for providing financial support. Present work has been carried out under the DST/TDT/AMT-sponsored project “Development of induction conduction based material deposition system for metal additive manufacturing” (DST/TDT/AMT/2017/119/G).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sharma, G.K., Pant, P., Jain, P.K., Kankar, P.K., Tandon, P. (2021). Thermal and Fluid Flow Modelling of a Heating Bed for Application in Metal AM Process. In: Kumar, A., Pal, A., Kachhwaha, S.S., Jain, P.K. (eds) Recent Advances in Mechanical Engineering . ICRAME 2020. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-9678-0_70

Download citation

DOI: https://doi.org/10.1007/978-981-15-9678-0_70

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9677-3

Online ISBN: 978-981-15-9678-0

eBook Packages: EngineeringEngineering (R0)