Abstract

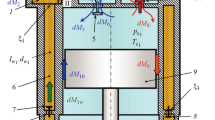

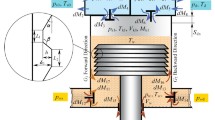

The question of mathematical modeling of the dynamic characteristics for a single-acting pneumatic drive of the clamping device for technological equipment, as well as research on its working process in the clamping pneumatic cylinder, is considered. The pneumatic settlement scheme for a drive is presented. The working stroke of the clamping pneumatic cylinder is performed when the compressed air is supplied to the piston cavity; the return stroke occurs under the action of the built-in spring. The mathematical model of the dynamic characteristics of the pneumatic drive has been developed. The mathematical model is based on the pneumatic cylinder piston’s motion equations, the piston cavity’s continuity equation, and the mass flow rate for air entering the piston cavity. The piston motion equations separately consider the positional load of the built-in spring, the resistance force proportional to the movement velocity, and the dry friction force. The thermodynamic process in the piston cavity of the pneumatic cylinder is adiabatic. The continuity equation considers the variable volume of the piston cavity and the volume of the connected pneumatic line. The equation for the mass flow rate of compressed air entering the pressure chamber of the pneumatic cylinder considers the subcritical and supercritical gas flow regimes. The example of calculating the dynamic characteristics for the clamping pneumatic cylinder is given. The presence of characteristic stages of the working process is shown.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Beater, P.: Pneumatic Drives. System Design, Modelling and Control. Springer, Berlin, Heidelberg (2007)

Fomin, O., Lovska, A.: Establishing patterns in determining the dynamics and strength of a covered freight car, which exhausted its resource. East. Eur. J. Enterprise Technol. 6(7(108)), 21–29 (2020). https://doi.org/10.15587/1729-4061.2020.217162

Abrahamova, T., Bushuyev, V., Gilova, L.: Metal-Cutting Machine Tools. Machinery Engineering, Moscow (2012)

Shevchenko, S., Mukhovaty, A., Krol, O.: Gear transmission with conic axoid on parallel axes. In: Radionov, A.A., Kravchenko, O.A., Guzeev, V.I., Rozhdestvenskiy, Y.V. (eds.) ICIE 2019. LNME, pp. 1–10. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-22041-9_1

Karpus, V.E., Ivanov, V.A.: Locating accuracy of shafts in V-blocks. Russ. Eng. Res. 32(2), 144–150 (2012). https://doi.org/10.3103/S1068798X1202013X

Ivanov, V., Vashchenko, S., Rong, Y.: Information support of the computer-aided fixture design system. In: CEUR Workshop Proceedings 1614, pp. 73–86 (2016)

Sokolova, Y.: The synthesis of system of automatic control of equipment for machining materials with hydraulic drive. East. Eur. J. Enterprise Technol. 2(2(68)), 56–68 (2014). https://doi.org/10.15587/1729-4061.2014.23396

Merzliakov, I., Pavlenko, I., Chekh, O., Sharapov, S., Ivanov, V.: Mathematical modeling of operating process and technological features for designing the vortex type liquid-vapor jet apparatus. In: Ivanov, V., et al. (eds.) DSMIE 2019. LNME, pp. 613–622. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-22365-6_61

Lovska, A., Fomin, O.: A new fastener to ensure the reliability of a passenger car body on a train ferry. Acta Polytech. 60(6), 478–485 (2020). https://doi.org/10.14311/AP.2020.60.0478

Pavlenko, I., Liaposhchenko, A., Ochowiak, M., Demyanenko, M.: Solving the stationary hydroaeroelasticity problem for dynamic deflection elements of separation devices. Vibr. Phys. Syst. 29, 2018026 (2018)

Schön, H.: Compressed gas cylinders. In: Handbook of Purified Gases, pp. 143–153. Springer, Berlin, Heidelberg (2015). https://doi.org/10.1007/978-3-540-32599-4_6

Tan, K.K., Putra, A.S.: Servo hydraulic and pneumatic drive. In: Tan, K.K., Putra, A.S. (eds.) Drives and Control for Industrial Automation, pp. 9–44. Springer, London (2011). https://doi.org/10.1007/978-1-84882-425-6_2

Kundrák, J., Mitsyk, A., Fedorovich, V., Markopoulos, A., Grabchenko, A.: Simulation of the circulating motion of the working medium and metal removal during multi-energy processing under the action of vibration and centrifugal forces. Machines 9(6), 118 (2021). https://doi.org/10.3390/machines9060118

Klinzing, G., Rizk, F., Marcus, R., Leung, L.: Control of pneumatic transport. In: Pneumatic Conveying of Solids. Particle Technology Series, vol. 8, pp. 459–474. Springer, Dordrecht (2010)

Kundrák, J., Mitsyk, A., Fedorovich, V., Markopoulos, A., Grabchenko, A.: Modeling the energy action of vibration and centrifugal forces on the working medium and parts in a vibration machine oscillating reservoir with an impeller. Manuf. Technol. 21(3), 364–372 (2021). https://doi.org/10.21062/mft.2021.042

Chung, J.: Coordinated control of a new pneumatic gripper. In: Kim, J.-H., Yang, W., Jo, J., Sincak, P., Myung, H. (eds.) Robot Intelligence Technology and Applications 3. AISC, vol. 345, pp. 561–570. Springer, Cham (2015). https://doi.org/10.1007/978-3-319-16841-8_50

Rasskazova, Y.: Automation of control processes of technological equipment with rotary hydraulic drive. East. Eur. J. Enterprise Technol. 2(2(80)), 44–50 (2016). https://doi.org/10.15587/1729-4061.2016.63711

Andrenko, P., Rogovyi, A., Hrechka, I., Khovanskyi, S., Svynarenko, M.: The influence of the gas content in the working fluid on parameters of the the hydraulic motor’s axial piston. In: Ivanov, V., Pavlenko, I., Liaposhchenko, O., Machado, J., Edl, M. (eds.) DSMIE 2021. LNME, pp. 97–106. Springer, Cham (2021). https://doi.org/10.1007/978-3-030-77823-1_10

Sokolov, V.: Transfer functions for shearing stress in nonstationary fluid friction. In: Radionov, A.A., Kravchenko, O.A., Guzeev, V.I., Rozhdestvenskiy, Y.V. (eds.) ICIE 2019. LNME, pp. 707–715. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-22041-9_76

Pavlenko, I.: Static and dynamic analysis of the closing rotor balancing device of the multistage centrifugal pump. Appl. Mech. Mater. 630, 248–254 (2014). https://doi.org/10.4028/www.scientific.net/AMM.630.248

Prydalnyi, B.I., Sulym, H.T.: Mathematical model of the tensioning in the collet clamping mechanism with the rotary movable input link on spindle units. J. Eng. Sci. 8(1), E23–E28 (2021). https://doi.org/10.21272/jes.2021.8(1).e4

Rogovyi, A., Korohodskyi, V., Khovanskyi, S., Hrechka, I., Medvediev, Y.: Optimal design of vortex chamber pump. J. Phys. Conf. Ser. 1741, 012018 (2021)

Rogovyi, A., Korohodskyi, V., Medvediev, Y.: Influence of Bingham fluid viscosity on energy performances of a vortex chamber pump. Energy 218, 119432 (2021). https://doi.org/10.1016/j.energy.2020.119432

Popov, D., Panaiotti, S., Ryabinin, M.: Hydromechanics. MSTU, Moscow (2014)

Sveshnikov, V.: Hydrodrives of Tools. Machinery Engineering, Moscow (2008)

Kovalevskyy, S., Kovalevska, O., Koshevoy, A., Tasić, I.: Using wave signatures for identifying mechanical objects. IOP Conf. Ser. Mater. Sci. Eng. 568, 012117 (2019)

Popov, D.: Mechanics of Hydro- and Pneumodrives. MSTU, Moscow (2001)

Loytsyanskiy, L.: Mechanics of Liquid and Gas. Drofa, Moscow (2003)

Nuruzzaman, M.: Modeling and Simulating in Simulink for Engineers and Scientists. Author-House, Bloomington (2004)

Tewari, A.: Modern Control Design with MATLAB and Simulink. John Wiley & Sons Ltd., Weinheim (2002)

Krol, O., Sokolov, V.: Modelling of spindle nodes for machining centers. J. Phys: Conf. Ser. 1084, 012007 (2018)

Sokolov, V., Porkuian, O., Krol, O., Baturin, Y.: Design calculation of electrohydraulic servo drive for technological equipment. In: Ivanov, V., Trojanowska, J., Pavlenko, I., Zajac, J., Peraković, D. (eds.) DSMIE 2020. LNME, pp. 75–84. Springer, Cham (2020). https://doi.org/10.1007/978-3-030-50794-7_8

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Sokolov, V., Krol, O., Golubenko, O., Tsankov, P., Marchenko, D. (2023). Dynamics of Clamping Pneumatic Cylinder for Technological Equipment. In: Tonkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Pavlenko, I. (eds) Advanced Manufacturing Processes IV. InterPartner 2022. Lecture Notes in Mechanical Engineering. Springer, Cham. https://doi.org/10.1007/978-3-031-16651-8_6

Download citation

DOI: https://doi.org/10.1007/978-3-031-16651-8_6

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-16650-1

Online ISBN: 978-3-031-16651-8

eBook Packages: EngineeringEngineering (R0)