Abstract

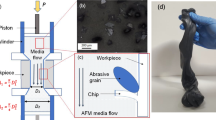

Additively manufactured (AM) parts generally have a higher surface roughness than parts manufactured using conventional methods. In most applications, a smooth surface finishing is preferred since rough surfaces are prone to corrosion attacks and fatigue crack incubation. Therefore, surface finishing is necessary to reduce the surface roughness of AM parts before they are used. The roughness of outer surfaces can be measured directly, using either contact stylus profilometer or non-contact optical microscope. However, there are still challenges to quantify the roughness of the internal surfaces using these conventional techniques of surface metrology. In this paper, we present a method to measure the roughness of internal channels by analyzing ultrasonic signals from the backwall reflection. A frequency-domain technique based on phase-screen approximation is used to reconstruct the root mean square (\(R_{q}\)) value from the ultrasonic signal scattered from the rough surfaces. Finite element simulations are developed to demonstrate the method, showing excellent accuracy when the \(R_{q}\) value is within 1/15 of the wavelength of the incident ultrasound. The method is then applied to monitor the surface roughness of the internal channels during the Abrasive Flow Machining (AFM) process. The reconstructed roughness value shows a clear and steady downward trend during the polishing process, quantitatively indicating the polishing rate. This demonstrates that such ultrasonic method can be used as a tool to provide feedback controls in the polishing process.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Chan, K.S., Koike, M., Mason, R.L., Okabe, T.: Fatigue life of titanium alloys fabricated by additive layer manufacturing techniques for dental implants. Metall Mater Trans A 44(2), 1010–1022 (2013). https://doi.org/10.1007/s11661-012-1470-4

Vayssette, B., Saintier, N., Brugger, C., Elmay, M., Pessard, E.: Surface roughness of Ti-6Al-4V parts obtained by SLM and EBM: effect on the high cycle fatigue life. Procedia Eng. 213, 89–97 (2018). https://doi.org/10.1016/j.proeng.2018.02.010

Blessing, G.V., Eitzen, D.G.: Ultrasonic measurements of surface roughness. In: Nondestructive Characterization of Materials, Saarbrücken, pp. 763–770 (1989). https://doi.org/10.1007/978-3-642-84003-6_88

Saniman, M.N.F., Ihara, I.: Application of air-coupled ultrasound to noncontact evaluation of paper surface roughness. J. Phys. Conf. Ser. 520, 012016 (2014). https://doi.org/10.1088/1742-6596/520/1/012016

Stor-Pellinen, J., Haeggström, E., Karppinen, T., Luukkala, M.: Air-coupled ultrasonic measurement of the change in roughness of paper during wetting. Meas. Sci. Technol. 12(8), 1336–1341 (2001). https://doi.org/10.1088/0957-0233/12/8/348

Stor-Pellinen, J., Luukkala, M.: Paper roughness measurement using airborne ultrasound. Sens. Actuators A 49(1), 37–40 (1995). https://doi.org/10.1016/0924-4247(95)01011-4

Chimenti, D.E.: Review of air-coupled ultrasonic materials characterization. Ultrasonics 54(7), 1804–1816 (2014). https://doi.org/10.1016/j.ultras.2014.02.006

Blessing, G., Slotwinski, J., Eitzen, D., Ryan, H.: Ultrasonic measurements of surface roughness. Appl. Optics 32(19), 3433–3437 (1993). https://doi.org/10.1364/AO.32.003433

Smith, R.A., Bruce, D.A.: Pulsed ultrasonic spectroscopy for roughness measurement of hidden corroded surfaces. Insight Non-Destruct. Test. Cond. Monit. 43(3), 168–172 (2001)

Ultrasonic spectroscopy using a rapid sweep technique. In: Presented at the 16th WCNDT 2004 - World Conference on NDT, Montreal, Canada (2004). Accessed 11 Sept 2021. https://www.ndt.net/article/wcndt2004/html/general_nde/543_buckley/543_buckley.htm

Sukmana, D.D., Ihara, I.: Surface roughness characterization through the use of diffuse component of scattered air-coupled ultrasound. Jpn. J. Appl. Phys. 45(5S), 4534 (2006). https://doi.org/10.1143/JJAP.45.4534

Wilhjelm, J.E., Pedersen, P.C., Jacobsen, S.M.: The influence of roughness, angle, range, and transducer type on the echo signal from planar interfaces. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 48(2), 511–521 (2001). https://doi.org/10.1109/58.911734

Adler, R.S., et al.: Quantitative assessment of cartilage surface roughness in osteoarthritis using high frequency ultrasound. Ultrasound Med. Biol. 18(1), 51–58 (1992). https://doi.org/10.1016/0301-5629(92)90008-X

Chiang, E.H., Adler, R.S., Meyer, C.R., Rubin, J.M., Dedrick, D.K., Laing, T.J.: Quantitative assessment of surface roughness using backscattered ultrasound: The effects of finite surface curvature. Ultrasound Med. Biol. 20(2), 123–135 (1994). https://doi.org/10.1016/0301-5629(94)90077-9

Shi, F., Lowe, M.J.S., Craster, R.V.: Recovery of correlation function of internal random rough surfaces from diffusely scattered elastic waves. J. Mech. Phys. Solids 99, 483–494 (2017). https://doi.org/10.1016/j.jmps.2016.11.003

Gunarathne, G.P.P., Christidis, K.: Measurements of surface texture using ultrasound. IEEE Trans. Instrum. Meas. 50(5), 1144–1148 (2001). https://doi.org/10.1109/19.963174

Nagy, P.B., Rose, J.H.: Surface roughness and the ultrasonic detection of subsurface scatterers. J. Appl. Phys. 73(2), 566–580 (1993). https://doi.org/10.1063/1.353366

Bhattacharjee, A., Pilchak, A.L., Lobkis, O.I., Foltz, J.W., Rokhlin, S.I., Williams, J.C.: Correlating ultrasonic attenuation and microtexture in a near-alpha titanium alloy. Metall. Mater. Trans. A 42(8), 2358–2372 (2011). https://doi.org/10.1007/s11661-011-0619-x

Garcia, N., Stoll, E.: Monte Carlo calculation for electromagnetic-wave scattering from random rough surfaces. Phys. Rev. Lett. 52(20), 1798–1801 (1984). https://doi.org/10.1103/PhysRevLett.52.1798

Huthwaite, P.: Accelerated finite element elastodynamic simulations using the GPU. J. Comput. Phys. 257, 687–707 (2014). https://doi.org/10.1016/j.jcp.2013.10.017

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this paper

Cite this paper

Sun, Z., Zuo, P., Pavlovic, M., Ang, Y.F., Fan, Z. (2023). In-Process Monitoring of Surface Roughness of Internal Channels Using. In: Rizzo, P., Milazzo, A. (eds) European Workshop on Structural Health Monitoring. EWSHM 2022. Lecture Notes in Civil Engineering, vol 270. Springer, Cham. https://doi.org/10.1007/978-3-031-07322-9_78

Download citation

DOI: https://doi.org/10.1007/978-3-031-07322-9_78

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-07321-2

Online ISBN: 978-3-031-07322-9

eBook Packages: EngineeringEngineering (R0)