Abstract

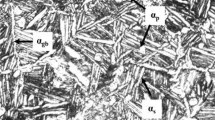

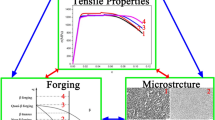

The quasi-beta forging behavior of Ti-55511 alloy is systematically studied by hot compressive deformation experiments and electron back-scattered diffraction (EBSD) tests. The results show that the strain rates have obvious effects on the hot deformation behaviors of the studied alloy. With the increase of strain rate, the flow stress increases. At low strain rates, the work hardening rates hardly change until a critical strain, and then the work hardening rates slightly increase. At a medium strain rate (0.1 s−1), the work hardening rate gradually decreases until a critical strain, and then the work hardening rate shows little variation with strain. However, at high strain rates (1 s−1), the positive work hardening rate indicates the obvious work hardening at the initial deformation stage, and the work hardening rates change to negative and then to positive with strain when the strain rate is further increased to 10 s−1. The main soften mechanism of β grain is DRV. With the increase of strain rate, the fraction of DRX grains and the sub-grains decrease. Too high strain rate leads to the formation of flow localization.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Lin YC, Tang Y, Zhang XY, Chen C, Yang H, Zhou KC (2019) Effects of solution temperature and cooling rate on microstructure and micro-hardness of a hot compressed Ti-6Al-4V alloy. Vacuum 159:191–199

Banerjee D, Williams JC (2013) Perspectives on titanium science and technology. Acta Mater 61:844–879

Lin YC, Huang J, Li H, Chen DD (2018) Phase transformation and constitutive models of a hot compressed TC18 titanium alloy in the α+β regime. Vacuum 157:83–91

Wang QW, Lin YC, Jiang YQ, Liu XG, Zhang XY, Chen DD, Chen C, Zhou KC (2019) Precipitation behavior of a β-quenched Ti-5Al-5Mo-5V-1Cr-1Fe alloy during high-temperature compression. Mater Charact 151:358–367

Guo LL, Fan XG, Yu G, Yang H (2016) Microstructure control techniques in primary hot working of titanium alloy bars: a review. Chin J Aeronaut 29:30–40

Kolli R, Devaraj A (2018) A review of metastable beta titanium alloys. Metals 8:506

Li C, Zhang XY, Li Z, Zhou KC (2013) Hot deformation of Ti-5Al-5Mo-5V-1Cr-1Fe near β titanium alloys containing thin and thick lamellar α phase. Mater Sci Eng A 573:75–83

Semiatin SL, Seetharaman V, Weiss I (1999) Flow behavior and globularization kinetics during hot working of Ti-6Al-4V with a colony alpha microstructure. Mater Sci Eng A 263:257–271

Lin YC, Jiang XY, Shuai CJ, Zhao CY, He DG, Chen MS, Chen C (2018) Effects of initial microstructures on hot tensile deformation behaviors and fracture characteristics of Ti-6Al-4V alloy. Mater Sci Eng A 711:293–302

Sen M, Suman S, Kumar M, Banerjee T, Bhattacharjee A, Kar SK (2018) Thermo-mechanical processing window for β phase recrystallization inTi-5Al-5Mo-5V-3Cr alloy. Mater Charact 146:55–70

Jiang YQ, Lin YC, Pang GD, He DG, Kotkunde N (2019) Constitutive model and processing maps for a Ti-55511 alloy in β region. Adv Eng Mater 1900930

Lei LM, Huang X, Wang MM, Wang LQ, Qin JN, Lu SQ (2011) Effect of temperature on deformation behavior and microstructures of TC11 titanium alloy. Mater Sci Eng A 528:8236–8243

Fan XG, Zhang Y, Gao PF, Lei ZN, Zhan M (2017) Deformation behavior and microstructure evolution during hot working of a coarse-grained Ti-5Al-5Mo-5V-3Cr-1Zr titanium alloy in beta phase field. Mater Sci Eng A 694:24–32

Shi XH, Shi CL, Zeng WD, Wang HJ, Jia ZQ (2015) Study on the fatigue crack growth rates of Ti-5Al5Mo-5V-1Cr-1Fe titanium alloy with basket-weave microstructure. Mater Sci Eng A 621:143–148

Wang KL, Lu SQ, Dong XJ, Li X, Ouyang DL (2016) Deformation behavior of Ti-5.6Al-4.8Sn-2.0Zr-1.0Mo-0.35Si-0.85Nd alloy in β/quasi-β forging process. J Iron Steel Res Int 23:1297–1302

Jiang YQ, Lin YC, Zhang XY, Chen C, Wang QW, Pang GD (2018) Isothermal tensile deformation behaviors and fracture mechanism of Ti-5Al-5Mo-5V-1Cr-1Fe alloy in β phase field. Vacuum 156:187–197

Lin YC, Pang GD, Jiang YQ, Liu XG, Zhang XY, Chen C, Zhou KC (2019) Hot compressive deformation behavior and microstructure evolution of a Ti-55511 alloy with basket-weave microstructures. Vacuum 169:108878

Ning YQ, Xie BC, Liang HQ, Li H, Yang XM, Guo HZ (2015) Dynamic softening behavior of TC18 titanium alloy during hot deformation. Mater Des 71:68–77

Guo HZ, Yao ZK, Ning YQ, Miao XP, Ge MM (2017) Effect of initial alpha lamellar thickness on deformation behavior of a near-α high-temperature alloy during thermomechanical processing. Mater Sci Eng A 682:345–353

Yang XM, Guo HZ, Liang HQ, Yao ZK, Yuan SC (2016) Flow behavior and constitutive equation of Ti-6.5Al-2Sn-4Zr-4Mo-1W-0.2Si titanium alloy. J Mater Eng Perform 25:1347–1359

Yamanaka K, Matsumoto H, Chiba A (2019) A constitutive model and processing maps describing the high-temperature deformation behavior of Ti-17 alloy in the β-phase field. Adv Eng Mater 21:1800775

Acknowledgments

This work was supported by the National Natural Science Foundation Council of China (Grant No. 51775564).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Jiang, YQ., Lin, Y.C., Pang, GD. (2021). Microstructural Evolution of Ti-55511 Titanium Alloy During Quasi-Beta Forging. In: Daehn, G., Cao, J., Kinsey, B., Tekkaya, E., Vivek, A., Yoshida, Y. (eds) Forming the Future. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-75381-8_99

Download citation

DOI: https://doi.org/10.1007/978-3-030-75381-8_99

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-75380-1

Online ISBN: 978-3-030-75381-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)