Abstract

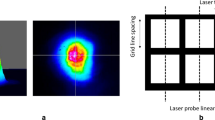

Femtosecond laser trimming procedure was optimized to reduce the edge curvature of diamond-coated WC (Co) punch as possible and to decrease the maximum roughness of diamond coatings. Bare diamond-coated WC (Co) punches with normal grain size were prepared to have an original film thickness of 9 μm. Through two laser machining steps, the edge width of diamond coating was reduced down to 2 μm. By using the core die with the clearance of 4%, fine piercing experiments were performed to measure the load–stroke relationship and to describe the affected zone formation by shearing. The affected zone area as well as the fractured surface ratio significantly decreased with a reduction of the edge width down to 2 μm.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Takeuchi S, Yokosawa T (2011) Fabrication and application of diamond films for dry forming die. Surf Eng 62 (3):152–156

Tamaoki K, Yokosawa T, Kataoka S (2012) Dry shearing of stainless steel sheets with polycrystalline diamond tools. Proc. 63rd JCTP: 191–192

https://www.ykt.co.jp/products/rollomatic/feature_lasersmart500.shtml (20/05/2019)

Aizawa T, Masaki E, Sugita Y (2014) Complete ashing of used DLC coating for reuse of the end-milling tools. Manufact Lett 2:1–3

Yunata EE, Aizawa T, Yamauchi K (2016) High density oxygen plasma ashing of CVD-diamond coating with minimum damage to WC (Co) tool substrates. Mech Eng JSME (2016) CD-ROM

https://www.i-precision.co.jp/rd.shtml (20/05/2019)

Watanabe M, Uchida H, Yamashita H, Miyatake K (2015) US-Patent Application 20150295252

Kawano M, Okamura S, Fujiyama T (2002) Non-oriented electrical steels having excellent magnetic properties and punchability for high speed micro-motors. Research Report, Kawasaki Steels 34:135–137

Weiss HA, Leuning N, Steentjes S, Hameyer K, Andorfer T, Jenner S, Vok W (2017) Influence of shear cutting parameters on the electromagnetic properties of non-oriented electrical steel sheets. J Magn Magn Mater 421:250–259

Cao H, Hao L, Yi J, Zhang X, Luo Z, Chen S, Li R (2016) The influence of punching process on residual stress and magnetic domain structure of non-oriented silicon steel. J Magn Magn Mater 406:42–47

K.W. Kontz, H. Li, Reducing core loss of segmented laminates, Proc. SMMA Fall Technical Conference (2008). (CD-ROM)

E. Katsuta, T. Aizawa, Y. Suzuki, K. Dohda, Effect of Clearance Control on the Micro-piercing Process of Electromagnetic steel sheets. Proc. 2017 Spring Conference for JSTP (2017) pp. 9–10

E. Katsuta, T. Aizawam K. Dohda, Micro-piercing of electromagnetic steel sheets by nitrided punch and die with nearly zero clearance. Proc. 10th AWMFT (2018, Pohang, Korea) (CD-ROM)

Katsuta E, Aizawa T, Morita H, Dohda K, Anzai M (2018) Fine piercing of electromagnetic steel sheets by micro-punches under nearly zero clearance. Procedia Manufacturing 15:1459–1466

E. Katsuta, T. Aizawa, K. Dohda, S-I. Yoshihara, Fabrication of lower temperature plasma nitrided die and development of zero-clearance piercing of electromagnetic steel sheets. J. JSTP 6- (2019) pp. 70–74

T. Aizawa, T. Inohara, Geometric adjustment and sizing of CVD-diamond coatings via oxygen plasma etching and laser machining., Proc. 7th SEATUC Conference, (Bandon, 2013) CD-ROM

T. Aizawa, T. Shiratori, T. Inohara, Short-pulse laser precise trimming of CVD-diamond coated punch for fine piercing. Proc. 3rd APSP Conference (August, 2019; Tokyo, Japan) pp. 41–46

T. Aizawa, T. Shiratori, T, Yoshino, T. Inohara, Femtosecond laser trimming of CVD-diamond coated punch for fine embossing. Mater. Trans. 61 (2020) (in press)

Aizawa T, Inohara T (2012) Multi-dimensional micro-patterning onto ceramics by pico-second laser machining. SIT Res. Rep. 56(1):17–26

Nomura K, Kubushiro K, Sakakibara Y, Takahashi S, Yoshizawa H (2012) Effect of Grain Size on Plastic Strain Analysis by EBSD for Austenitic Stainless Steels with Tensile Strain at 650°C. J Soc Mater Sci Jpn, 61–4:371–376

Aizawa T, Shiratori T, Yoshino T, Dohda K, Shingaki Y (in press) Material characterization on the affected zones by fine piercing into single crystal Fe-3Si steel sheet. Proc. WCMNM2020 (2020, India)

Senda K, Ishida M, Nakasu Y, Yagi M (2005) Effect of Shearing Process on Iron Loss and Domain Structure of Non-oriented Electrical Steel. IEE J Trans FM 125–3:241–246

Acknowledgments

The authors would like to express their gratitude to Mr. Y. Suzuki, Mr. T. Yoshino, Mr. T. Aihara (Komatsu-Seiki Kosakusho, Co., Ltd.), and Mr. T. Inohara (LPS-Works, Co., Ltd.) for their help in experiments. This study was financially supported in part by the METI-project on the Supporting Industry Program in 2019.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Aizawa, T., Shiratori, T. (2021). Fine-Piercing of Electrical Steel Sheets by Edge-Sharpened Diamond Punch. In: Daehn, G., Cao, J., Kinsey, B., Tekkaya, E., Vivek, A., Yoshida, Y. (eds) Forming the Future. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-75381-8_233

Download citation

DOI: https://doi.org/10.1007/978-3-030-75381-8_233

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-75380-1

Online ISBN: 978-3-030-75381-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)