Abstract

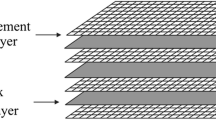

In this study, polyphenylene sulfide (PPS) composite, which has ultra-high content of carbon fiber fabrics (CFF), was prepared from CFF and PPS nonwoven by a facile thermal-compressive method. The results show that the PPS composite composed of 80 wt% CFFs has optimal mechanical properties, where the tensile strength, fracture elongation, elastic modulus, flexural strength, flexural modulus, interlaminar shear strength, and impact strength reach to 1200.3 MPa, 20.3%, 25.7 GPa, 1305.6 MPa, 230.6 GPa, 110.3 MPa, and 348.6 KJ/m2, respectively. In addition, the volume resistivity, conductivity, and surface resistivity of the PPS composite with 80 wt% CFFs can reach to 1.3 × 10−2 Ω·cm, 74.9 S/cm, and 1.2 × 10−1 Ω·□ respectively. The increased interfacial layer and riveting effect between CFFs are responsible for outstanding structural stability and stress transformation, resulting in ultra-high strength and modulus of CFF/PPS composite, as well as the conductive performance.

Schematic diagram of failure mechanism and optical microscope images of cross sections of CFF/PPS composites.

Similar content being viewed by others

References

Liu YJ, Du HY, Liu LW, Leng JS (2014) Shape memory polymers and their composites in aerospace applications: a review. Smart Mater Struct 23(2):23001–23022

Hakim IA, Donaldson SL, Meyendorf NG, Browning CE (2017) Porosity effects on interlaminar fracture behavior in carbon fiber-reinforced polymer composites. Mater Sci Appl 8:170–187

Ozdemir NG (2016) Toughening of carbon fibre reinforced polymer composites with rubber nanoparticles for advanced industrial applications. Express Polym Lett 10:394–407

Shiino MY, Cioffi MOH, Voorwald HCJ, Ortiz EC (2013) Tricot stitched carbon fiber reinforced polymer composite laminates manufactured by resin transfer molding process: C-scan and flexural analysis. J Compos Mater 47(14):1695–1703

Kuang T, Ju JJ, Yang ZY, Geng LH, Peng XF (2018) A facile approach towards fabrication of lightweight biodegradable poly (butylene succinate)/carbon fiber composite foams with high electrical conductivity and strength. Compos Sci Technol 159:171–179

Nishikawa M, Fukuzo A, Matsuda N, Hojo M (2018) Evaluation of elastic-plastic response of discontinuous carbon fiber-reinforced thermoplastics: experiments and considerations based on load-transfer-based micromechanical simulation. Compos Sci Technol 155:117–125

Ye L, Chen ZR, Lu M, Hou M (2005) De-consolidation and re-consolidation in CF/PPS thermoplastic matrix composites. Compos Part A 36(7):915–922

Huang YX, Meng XC, Xie YM, Lv ZL, Wan L, Cao J, Feng JC (2018) Friction spot welding of carbon fiber-reinforced polyetherimide laminate. Compos Struct 189:627–634

Mahat KB, Alarifi I, Alharbi A, Asmatulu R (2016) Effects of UV light on mechanical properties of carbon fiber reinforced PPS thermoplastic composites. Macromol Symp 365(1):157–168

Blond D, Vieille B, Gomina M, Taleb L (2014) Correlation between physical properties, microstructure and thermo-mechanical behavior of PPS-based composites processed by stamping. J Reinforc Plast Compos 33(17):1656–1668

Zhao YF, Xiao M, Wang SJ, Ge XC, Meng YZ (2007) Preparation and properties of electrically conductive PPS/expanded graphite nanocomposites. Compos Sci Technol 67:2528–2534

Xing J, Ni QQ, Deng B, Liu Q (2016) Morphology and properties of polyphenylene sulfide (PPS)/polyvinylidene fluoride (PVDF) polymer alloys by melt blending. Compos Sci Technol 134:184–190

Vieille B, Aucher J, Taleb L (2011) Influence of temperature on the behavior of carbon fiber fabrics reinforced PPS laminates. Adv Polym Technol 517(1–2):51–60

Stoeffler K, Andjelic S, Legros N, Roberge J, Schougaard SB (2013) Polyphenylene sulfide (PPS) composites reinforced with recycled carbon fiber. Compos Sci Technol 84:65–71

Rao J, Liang ZY (1996) Preparation of PPS/CF composites by suspension method. Polym Mater Sci Eng 4:59–62

Huang H, Li Y, Zhao L, Yu Y, Xu J, Yin YZ, Chen SH, Wu J, Yue HS, Wang H, Wang LX (2019) A facile fabrication of chitosan modified PPS-based microfiber membrane for effective antibacterial activity and oil-in-water emulsion separation. Cellulose 26(4):2599–2611

Huang H, Liu M, Li Y, Yu Y, Yin XZ, Wu J, Chen SH, Xu J, Wang LX, Wang H (2018) Polyphenylene sulfide microfiber membrane with superhydrophobicity and superoleophilicity for oil/water separation. J Mater Sci 53(18):13243–13252

Luo D, Chen M, Xu J, Yin XZ, Wu J, Chen SH, Wang LX, Wang H (2018) Polyphenylene sulfide nonwoven-based composite separator with superior heat-resistance and flame retardancy for high power lithium ion battery. Compos Sci Technol 157:119–125

Wang P, He CC, Hu LQ, Chen SH, Yin XZ, Xu J, Wang LX, Wang H (2018) Load of Ag3PO4 particles on sulfonated polyphenylene sulfide superfine fibre with high visible light photocatalytic activity. Fiber Polym 19(7):1379–1385

Liu M, Yu Y, Xiong SW, Lin PL, Hu LQ, Chen SH, Wang H, Wang LX (2019) A flexible and efficient electro-Fenton cathode film with aeration function based on polyphenylene sulfide ultra-fine fiber. React Funct Polym 139:42–49

Zhao L, Yu Y, Huang H, Yin XZ, Peng JS, Sun JX, Huang LP, Tang YH, Wang LX (2019) High-performance polyphenylene sulfide composites with ultra-high content of glass fiber fabrics. Compos Part B 174:106790

Auerbach AB, Harmon WS (1997) Melt-blown polyarylene sulfide microfibers and method of making the same. US US5695869

Liu D, Zhu YD, Ding JP, Lin XY, Fan XY (2015) Experimental investigation of carbon fiber reinforced poly(phenylene sulfide) composites prepared using a double-belt press. Compos Part B 77:363–370

Jing PZ, Zhu S, Yu MH, Yuan XG, Liu WP, Jiang ZF (2016) Preparation of carbon fiber fabric reinforced polyphenylene sulfide (CFF/PPS) thermoplastic composites based on surface modification of carbon fibers. J Mater Eng 44(3):21–27

Khan SM, Gull N, Munawar MA, Zia S, Anjum F, Iqbal MS, Shafiq M, Islam A, Awais SM, Butt MA, Butt MTZ, Jamil T (2016) Polyphenylene sulphide/carbon fiber composites: study on their thermal, mechanical and microscopic properties. Iran Polym J 25(6):475–485

Liu D, Zhu YD, Ding JP, Lin XY, Fan YY (2015) Experimental investigation of carbon fiber reinforced poly(phenylene sulfide) composites prepared using a double-belt press. Compos Part B 77:363–370

Maiti SN (2007) Effect of maleation on polyamide-6/EPDM-G-MAH blends. Soft Mater 4(1):85–100

Desio GP, Rebenfeld L (1992) Crystallization of fiber-reinforced poly(phenylene sulfide) composites. II. Modeling the crystallization kinetics. J Appl Polym Sci 45(11):2005–2020

Martínez-Tong DE, Vanroy B, Wübbenhorst M, Nogales A, Napolitano S (2014) Crystallization of poly(l-lactide) confined in ultrathin films: competition between finite size effects and irreversible chain adsorption. Macromolecules 47(7):2354–2360

Ma Y, Yokozeki T, Ueda M, Sugahara T, Yang YQ, Hamada H (2017) Effect of polyurethane dispersion as surface treatment for carbon fabrics on mechanical properties of carbon/nylon composites. Compos Sci Technol 151:268–281

Liao M, Yang YQ, Hamada H (2016) Mechanical performance of glass woven fabric composite: effect of different surface treatment agents. Compos Part B 86:17–26

Ma Y, Ueda M, Yokozeki T, Sugahara T, Yang YQ, Hamada H (2017) A comparative study of the mechanical properties and failure behavior of carbon fiber/epoxy and carbon fiber/polyamide 6 unidirectional composites. Compos Struct 160:89–99

Felfel RM, Ahmed I, Parsons AJ, Walker GS, Rudd CD (2011) In vitro degradation, flexural, compressive and shear properties of fully bioresorbable composite rods. J Mech Behav Biomed Mater 4(7):1462–1472

Edwards KL (1998) An overview of the technology of fibre-reinforced plastics for design purposes. Mater Design 19(1–2):1–10

Ishida H, Koenig JL (1978) Fourier transform infrared spectroscopic study of the silane coupling agent/porous silica interface. J Colloid Interf Sci 64(3):555–564

Iglesias JG, González-Benito J, Aznar AJ, Bravo J, Baselga J (2002) Effect of glass fiber surface treatments on mechanical strength of epoxy based composite materials. J Colloid Interf Sci 250(1):251–260

Yang SW, Liu JC, Pan F, Yin XZ, Wang LX, Chen DZ, Zhou YS, Xiong CX, Wang H (2016) Fabrication of self-healing and hydrophilic coatings from liquid-like graphene@SiO2 hybrids. Compos Sci Technol 136:133–144

Zhou H, Du XS, Liu HY, Zhou HM, Zhang Y, Mai YW (2017) Delamination toughening of carbon fiber/epoxy laminates by hierarchical carbon nanotube-short carbon fiber interleaves. Compos Sci Technol 140:46–53

Prabhu P, Mohamed Iqbal S, Balaji A, Karthikeyan B (2018) Experimental investigation of mechanical and machining parameters of hybrid nanoclay glass fiber-reinforced polyester composites. Adv Compos Hybrid Mater 2:93–101

Zhou LM, Kim JK, Mai YW (1993) Micromechanical characterisation of fibre/matrix interfaces. Compos Sci Technol 48(1–4):227–236

Gopinath R, Poopathi R, Saravanakumar SS (2019) Characterization and structural performance of hybrid fiber-reinforced composite deck panels. Adv Compos Hybrid Mater 2(1):115–124

Zhou H, Du X, Liu HY, Zhou HM, Zhang Y, Mai YW (2017) Delamination toughening of carbon fiber/epoxy laminates by hierarchical carbon nanotube-short carbon fiber interleaves. Compos Sci Technol 140:46–53

Kumaria S, Singh RN, Gupta V (2010) Effect of interfacial shear strength on crack-fiber interaction behavior in ceramic matrix composites. J Am Ceram Soc 79(1):199–208

Martin E, Leguillon D, Lacroix C (2001) A revisited criterion for crack deflection at an interface in a brittle bimaterial. Compos Sci Technol 61(12):1671–1679

Yang XT, Liang CB, Ma TB, Guo YQ, Kong J, Gu JW, Chen MJ, Zhu JH (2018) A review on thermally conductive polymeric composites: classification, measurement, model and equations, mechanism and fabrication methods. Adv Compos Hybrid Mater 1:207–230

Funding

This work was supported by the National Science and Technology Support Program (2015BAE01B04).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, L., Ge, Q., Sun, J. et al. Fabrication and characterization of polyphenylene sulfide composites with ultra-high content of carbon fiber fabrics. Adv Compos Hybrid Mater 2, 481–491 (2019). https://doi.org/10.1007/s42114-019-00111-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-019-00111-w