Abstract

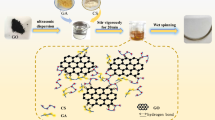

Reduced graphene oxide (rGO) which was nontoxic, reduced from graphene oxide (GO), and decorated was mixed with chitosan (CS) solution to prepare rGO/chitosan (rGO/CS) biocomposite fiber by dry-jet wet spinning. rGO-/genipin-cross-linked CS (rGO/GCS) composite fiber was prepared. The conditions on nontoxic reduction of GO, namely decoration, spinning, drawing, and nontoxic cross-linking, were studied and optimized. The way to disperse rGO homogeneously in spinning solution was discussed. After surface decorating, rGO was covered by CS without reunion. No phase separation in rGO/CS spinning solution was observed. The solution remained stable for a week after being diluted. The decoration of CS was an effective way to achieve homogeneous dispersion of rGO in solution for spinning. Raman spectroscopy, Fourier-transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), scanning electron microscope (SEM), transmission electron microscopy (TEM), and fluorescence spectroscopy were used to characterize the fibers and their precursors. A series of rGO/CS fibers with a diameter of 0.1 mm were successfully fabricated. The well-dispersed and exfoliated rGO nanosheets were assembled in CS matrix. Both rGO/CS fibers and rGO/GCS fibers maintained the intrinsic fluorescence. Both uncross-linked and cross-linked composite fibers could be bent freely. The work built up the foundation for systematic conductivity and mechanical property research about rGO/CS composite fibers.

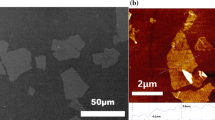

The thickness of rGO is several nanometers, and the rGO has exfoliated into nanoscale fillers.

Similar content being viewed by others

References

Dvir T, Timko B, Kohane D, Langer R (2011) Nanotechnological strategies for engineering complex tissues. Nat Nanotechnol 69:13–22

Guilak F, Cohen D, Estes B, Gimble J, Liedtke W, Chen C (2009) Control of stem cell fate by physical interaction with the extracellular matrix. Cell Stem Cell 5:17–26

Engler A, Sen S, Sweeney H, Dischr D (2006) Matrix elasticity directs stem cell lineage specification. Cell 126:677–689

Moutos F, Freed L, Guilak F (2007) A biomimetic three-dimensional woven composite scaffold for functional tissue engineering of cartilage. Nat Mater 6:162–167

Krachenbuehl T, Langer R, Ferreira L (2011) Three-dimensional biomaterials for the study of human pluripotent stem cells. Nat Methods 8:731–736

Tuzlakoglu K, Alves C, Mano J, Reis R (2004) Production and characterization of chitosan fibers and 3-D fiber mesh scaffolds for tissue engineering applications. Macromol Biosci 4:811–819

Suh J, Matthew H (2000) Application of chitosan-based polysaccharide biomaterials in cartilage tissue engineering: a review. Biomaterials 21:2589–2598

Kumar R (2000) A review of chitin and chitosan applications. React Funct Polym 46:1–27

Lauto A, Ohebshalom M, Esposito M, Mingin J, Li P, Felsen D, Goldstein M, Poppas D (2001) Self-expandable chitosan stent: design and preparation. Biomaterials 22:1869–1874

Tada D, Singh S, Nagesha D, Jost E, Levy C, Gultepe E, Cormack R, Makrigiorgos G, Sridhar S (2010) Chitosan film containing poly (D, L-lactic-co-glycolic acid) nanoparticles: a platform for localized dual-drug release, Pharm Res 27: 1738–1745

Jin J, Song M, Hourston D (2004) Novel chitosan-based films cross-linked by genipin with improved physical properties. Biomacromolecules 5:162–168

Mi F, Tan Y, Liang H, Sung H (2002) In vivo biocompatibility and degradability of a novel injectable-chitosan-based implant. Biomaterials 23:181–191

Wang G, Zheng L, Zhao H, Miao J, Sun C, Ren N, Wang J, Liu H, Tao X (2011) In vitro assessment of the differentiation potential of bone marrow-derived mesenchymal stem cells on genipin-chitosan conjugation scaffold with surface hydroxyapatite nanostructure for bone tissue engineering. Tissue Eng Part A 17:1341–1349

Li N, Zhang Q, Gao S, Song Q, Huang R, Wang L, Liu L, Dai J, Tang M, Cheng G (2013) Three-dimensional graphene foam as a biocompatible and conductive scaffold for neural stem cells. Sci Rep 3:1604

Chang Y, Yang S, Liu J, Dong E, Wang Y, Cao A, Liu Y, Wang H (2011) In vitro toxicity evaluation of graphene oxide on A549 cells. Toxicol Lett 200:201–210

Feng L, Liu Z (2011) Graphene in biomedicine: opportunities and challenges. Nanomedicine 6:317–324

Li J, Ren N, Qiu J, Mou X, Liu H (2013) Graphene oxide-reinforced biodegradable genipin-cross-linked chitosan fluorescent biocomposite film and its cytocompatibility. Int J Nanomedicine 8:3415–3426

Geim A, Novoselov K (2007) The rise of graphene. Nat Mater 6:183–191

Stankovich S, Dikin D, Piner R, Kohlhaas K, Kleinhammes A, Kevin A, Jia Y, Wu Y, Nguyen S, Ruoff R (2007) Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 45:1558–1565

Zhang J, Yang H, Shen G, Cheng P, Zhang J, Guo S (2010) Reduction of graphene oxide via L-ascorbic acid. Chem Commun 46:1112–1114

Guo H, Wang X, Qian Q, Wang F, Xia X (2009) A green approach to the synthesis of graphene nanosheets. ACS Nano 3:2653–2659

Guo S, Wen D, Zhai Y, Dong S, Wang E (2010) Platinum nanoparticle ensemble-on-graphene hybrid nanosheet: one-pot, rapid synthesis, and used as new electrode material for electrochemical sensing. ACS Nano 4:3959–3968

Park S, Ruoff R (2009) Chemical methods for the production of graphenes. Nat Nanotechnol 4:217–224

Sun X, Liu Z, Welsher K, Robinson J, Goodwin A, Zaric S, Dai H (2008) Nano-graphene oxide for cellular imaging and drug delivery. Nano Res 1:203–212

Zhang L, Xia J, Zhao Q, Liu L, Zhang Z (2010) Functional graphene oxide as a nanocarrier for controlled loading and targeted delivery of mixed anticancer drugs. Small 6:537–544

Rana V, Choi M, Kong J, Kim G, Kim M, Kim S (2011) Synthesis and drug-delivery behavior of chitosan-functionalized graphene oxide hybrid nanosheets. Macromol Mater Eng 296:131–140

Wang Y, Li Z, Hu D, Lin C, Li J, Lin Y (2010) Aptamer/graphene oxide nanocomplex for in situ molecular probing in living cells. J Am Chem Soc 132:9274–9276

Zhang J, Zhang F, Yang H, Huang X, Liu H, Zhang J, Guo S (2010) Graphene oxide as a matrix for enzyme immobilization. Langmuir 26:6083–6085

Zhang Y, Zhang J, Huang X, Zhou X, Wu H, Guo S (2012) Assembly of graphene oxide-enzyme conjugates through hydrophobic interaction. Small 8:154–159

Wan Y, Wang Y, Wu J, Zhang D (2011) Graphene oxide sheet-mediated silver enhancement for application to electrochemical biosensors. Anal Chem 83:648–653

Song W, Li D, Li Y, Li Y, Long Y (2011) Disposable biosensor based on graphene oxide conjugated with tyrosinase assembled gold nanoparticles. Biosens Bioelectron 26:3181–3186

Dreyer D, Park S, Bielawski C, Ruoff R (2010) The chemistry of graphene oxide. Chem Soc Rev 39:228–240

Xu Y, Hong W, Bai H, Li C, Shi G (2009) Strong and ductile poly (vinyl alcohol)/graphene oxide composite films with a layered structure. Carbon 47:3538–3543

Depan D, Girase B, Shah J, Misra R (2011) Structure-process-property relationship of the polar graphene oxide-mediated cellular response and stimulated growth of osteoblasts on hybrid chitosan network structure nanocomposite scaffolds. Acta Biomater 7:3432–3445

Deng L, Wang K, Zhao C, Yan H, Britten J, Xu G (2011) Phase and texture of solution-processed copper phthalocyanine thin films investigated by two- dimensional grazing incidence X-ray diffraction. Crystals 1:112–119

Zhao C, Xiao S, Xu G (2015) Density of organic thin films in organic photovoltaics. J Appl Phys 118:044510

Zhao C, Wang K, Britten J, Zhi M, Wang X, Chen Z, Xu G (2012) Dual nanostructures in poly (3-hexylthiophene) based organic photovoltaics under alternative current electric field. Thin Solid Films 520:5770–5774

Funding

This work was supported by the Fundamental Research Funds for the Central Universities (no. 53200859721 and no.2-9-2017-346) and the Innovation and Entrepreneurship Training Project for Undergraduate Students (2016AX031), China University of Geosciences, Beijing.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Zhang, C., Zhang, Y., Hao, X. et al. Fabrication of reduced graphene oxide/chitosan composite fiber by dry-jet wet spinning. Adv Compos Hybrid Mater 1, 347–355 (2018). https://doi.org/10.1007/s42114-018-0029-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42114-018-0029-2