Abstract

Zn–Al layered double hydroxide (LDH) intercalated with various corrosion inhibitors namely vanadate (E1), 2-mercapto benzothiazole (E3), molybdate (E7), phytic acid (E8) and 8-hydroxyquinoline (E9) was dispersed in a hybrid sol–gel silica matrix sol. Bilayer coatings with configurations E3|E1, E7|E1, E8|E1 and E9|E1 were generated on aluminum alloy AA 2024-T3 substrates using the inhibitor intercalated LDH modified sols by dip coating technique followed by UV curing and thermal curing at 80°C for 1 h in air. Corrosion resistance of coatings deposited from matrix sol with and without inhibitor intercalated LDH was studied by electrochemical impedance spectroscopy, potentiodynamic polarization after exposure to 3.5% NaCl and salt spray tests, results of which were compared with those of uncoated and chromated substrates. A non-chromated primer was applied on the sol–gel coated substrates. Adhesion of the coatings to the substrate and to the primer was evaluated by peel-off tape test and found to be rank 5. The sol–gel coated substrates did not exhibit corrosion during salt spray tests. Electrochemical tests showed that all the sol–gel coated substrates exhibited superior corrosion resistance when compared to bare and chromated substrates. More specifically, coatings generated using the corrosion inhibitors phytic acid and 8-hydroxy quinoline intercalated Zn–Al LDH were seen to render maximum corrosion protection, exhibiting two orders of magnitude lower corrosion currents than bare substrates and one order lower corrosion current than chromated substrate, after 120-h exposure to 3.5% NaCl solution.

Similar content being viewed by others

References

Burakowski, T, Wierzchon, W, Surface Engineering of Metals: Principles, Equipment Technologies. CRC Press, Boca Raton (1999)

Koch, GH, Brongers, MP, Thompson, NG, Virmani, YP, Payer, JH, “Corrosion Costs and Preventive Strategies in the United States”. FHWA-RD-01-156, U. S. Department of Transportation, Federal Highway Administration, Washington, DC (2001)

Kendig, MW, Davenport, A, Isaacs, HS, “The Mechanism of Corrosion Inhibition by Chromate Conversion Coatings from X-Ray Absorption Near Edge Spectroscopy (Xanes).” Corr. Sci., 34 41–49 (1993)

Lytle, FW, Greegor, RB, Bibbins, GL, Blohowiak, KY, Smith, RE, Truss, GD, “An Investigation of the Structure and Chemistry of a Chromium-Conversion Surface Layer on Aluminum.” Corros. Sci., 37 349–369 (1995)

Zhao, J, Xia, L, Sehgal, A, Lu, D, McCreery, RL, Frankel, G, “Effects of Chromate and Chromate Conversion Coatings on Corrosion Of Aluminum Alloy 2024 T3.” Surf. Coat. Technol., 140 51–57 (2001)

Xia, L, Akiyama, E, Frankel, G, McCreery, RL, “Storage and Release of Soluble Hexavalent Chromium from Chromate Conversion Coatings Equilibrium Aspects of Cr+4 Concentration.” J. Electrochem. Soc., 147 2556–2562 (2000)

Kulinich, SA, Akhtar, AS, “On Conversion Coating Treatments to Replace Chromating for Al Alloy: Recent Developments and Possible Future Directions.” Russ. J. Non-ferrous Metals., 53 176–203 (2012)

Droniou, P, Fristad, WE, Liang, JL, “Nanoceramic-Based Conversion Coating: Ecological and Economic Benefits Position Process as a Viable Alternative to Phosphating Systems.” Met. Finish, 103 41–43 (2005)

Wang, D, Bierwagen, GP, “Review: “Sol–Gel Coatings on Metals for Corrosion Protection.” Prog. Org. Coat., 64 327–338 (2008)

Zheludkevich, ML, Salvado, IM, Ferreira, MGS, “Sol–Gel Coatings for Corrosion Protection of Metals.” J. Mater. Chem., 15 5099–5111 (2005)

Duran, A, Castro, Y, Aparicio, M, Conder, A, Damborenea, JJ, “Protection and Surface Modification of Metals with Sol–Gel Coatings.” Int. Mater. Rev., 52 175–190 (2007)

Conde, A, Durán, A, Damborenea, JJ, “Polymeric Sol–Gel Coatings as Protective Layers of Aluminium Alloys.” Prog. Org. Coat., 464 288–296 (2003)

Rosero-Navarro, NC, Curioni, M, Bingham, R, Durán, A, Aparicio, M, Cottis, RA, Thompson, GE, “Electrochemical Techniques for Practical Evaluation of Corrosion Inhibitor Effectiveness. Performance of Cerium Nitrate as Corrosion Inhibitor for AA2024T3 Alloy.” Corros. Sci., 52 (10) 3356–3366 (2010)

Pellice, S, Galliano, P, Castro, Y, Durán, A, “Hybrid Sol–Gel Coatings Produced from TEOS and γ-MPS.” J. Sol–Gel Sci. Technol., 28 81–86 (2003)

Shchukin, DG, Zheludkevich, ML, Yasakau, K, Lamaka, S, Ferreira, MGS, Möhwald, H, “Layer-by-Layer Assembled Nanocontainers for Self-Healing Corrosion Protection.” Adv. Mater., 18 1672–1678 (2006)

Skorb, EV, Fix, D, Andreeva, DV, Mohwald, H, Shchukin, DG, “Surface-Modified Mesoporous SiO2 Containers for Corrosion Protection.” Adv. Funct. Mater., 19 2373–2379 (2009)

Tedim, J, Poznyak, SK, Kuznetsova, A, Raps, D, Hack, T, Zheludkevich, ML, Ferreira, MGS, “Enhancement of Active Corrosion Protection via Combination of Inhibitor-Loaded Nanocontainers.” ACS Appl. Mater. Interfaces, 2 1528–1535 (2010)

Mishra, T, Mohanty, AK, Tiwari, SK, “Recent Development in Clay Based Functional Coating for Corrosion Protection.” Key Eng. Mater., 571 93–109 (2013)

Lvov, YM, Shchukin, DG, Mohwald, H, Price, R, “Halloysite Clay Nanotubes for Controlled Release of Protective Agents.” ACS Nano, 2 814–820 (2008)

Joshi, A, Abdullayev, E, Vasiliev, A, Volkova, O, Lvov, Y, “Interfacial Modification of Clay Nanotubes for the Sustained Release of Corrosion Inhibitors.” Langmuir, 29 7439–7448 (2013)

Abdullayev, E, Price, R, Shchukin, D, Lvov, Y, “Halloysite Tubes as Nanocontainers for Anticorrosion Coating with Benzotriazole.” ACS Appl. Mater. Interfaces, 1 1437–1443 (2009)

Lanzara, G, Yoon, Y, Liu, H, Peng, S, Lee, WI, “Carbon Nanotube Reservoirs for Self-Healing Materials.” Nanotechnology, 20 335704–335711 (2009)

Jung, IK, Gurav, JL, Bangi, UKH, Baek, S, Park, HH, “Silica Xerogel Films Hybridized with Carbon Nanotubes by Single Step Sol–Gel Processing.” J. Non-Cryst. Solids, 358 550–556 (2012)

Zheludkevich, ML, Poznyak, SK, Rodrigues, LM, Raps, D, Hack, T, Dick, LF, Nunes, T, Ferreira, MGS, “Active Protection Coatings with Layered Double Hydroxide Nanocontainers of Corrosion Inhibitor.” Corros. Sci., 52 602–611 (2010)

Tedim, J, Zheludkevich, ML, Salak, AN, Lisenkov, A, Ferreira, MGS, “Nanostructured LDH-Container Layer with Active Protection Functionality.” J. Mater. Chem., 21 15464–15470 (2011)

Stimpfling, T, Leroux, F, Hintze-Bruenning, H, “Organo-Modified Layered Double Hydroxide in Coating Formulation to Protect AA 2024 from Corrosion.” Colloids Surf. A, 458 147–154 (2014)

Harvey, TG, “Cerium-Based Conversion Coatings on Aluminium Alloys: A Process Review.” Corros. Eng Sci Technol., 48 248–269 (2013)

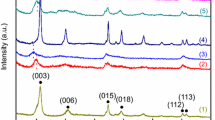

Salak, AN, Tedim, J, Kuznetsova, AI, Zheludkevich, ML, Ferreira, MGS, “Anion Exchange in Zn–Al Layered Double Hydroxides: In Situ X-Ray Diffraction Study.” Chem. Phys. Lett., 495 73–76 (2010)

Dong, Y, Wang, F, Zhou, Q, “Protective Behaviours of 2-Mercaptobenzothiazole Intercalated Zn–Al-Layered Double Hydroxide Coating.” J. Coat. Technol. Res., 11 (5) 793–803 (2014)

Zheludkevich, ML, Poznyak, SK, Rodrigues, LM, Raps, D, Hack, T, Dick, LF, Nunes, T, Ferreira, MGS, “Active Protection Coatings with Layered Double Hydroxide Nanocontainers of Corrosion Inhibitor.” Corros. Sci., 52 602–611 (2010)

Wang, Y, Zhang, D, “Synthesis, Characterization and Controlled Release Anticorrosion Behavior of Benzoate Intercalated Zn–Al Layered Double Hydroxides.” Mater. Res. Bull., 46 1963–1968 (2011)

Liu, J, Zhang, Y, Yu, M, Li, S, Xue, B, Yin, X, “Influence of Embedded ZnAlCe–NO3 − Layered Double Hydroxides on the Anticorrosion Properties of Sol–Gel Coatings for Aluminum Alloy.” Progr. Org. Coat., 81 93–100 (2015)

Shi, H, Han, EH, Liu, F, Kallip, S, “Protection of 2024-T3 Aluminium Alloy by Corrosion Resistant Phytic Acid Conversion Coating.” Appl. Surf. Sci., 280 325–331 (2013)

Gao, HF, Zhang, ST, Liu, CL, Xu, JQ, Li, J, “Phytic Acid Conversion Coating on AZ31B Magnesium Alloy.” Surf. Eng., 28 387–392 (2012)

Zhong, Y, Yingjun, Z, Jingwei, D, Qingsong, Y, Yawei, S, Yanqiu, W, Guozhe, M, “Effect of Phytic Acid on Corrosion Performance of Epoxy Coating on Rust Q235 Carbon Steel.” Corros. Sci. Prot. Technol., 27 183–187 (2015)

Chou, TP, Chandrasekaran, C, Cao, GZ, “Sol–Gel Derived Hybrid Coatings for Corrosion Protection.” J. Sol-Gel Sci. Technol., 26 321–327 (2003)

Chou, TP, Chandrasekaran, C, Limmer, SJ, Nguyen, C, Cao, GZ, “Organic–Inorganic Sol–Gel Coating for Corrosion Protection of Stainless Steel.” J. Mater. Sci. Lett., 21 251–255 (2002)

Chou, TP, Chandrasekaran, C, Limmer, SJ, Seraji, S, Wu, Y, Forbess, MJ, Nguyen, C, Cao, GZ, “Organic–Inorganic Hybrid Coatings for Corrosion Protection.” J. Non-Cryst. Solids, 290 153–162 (2001)

Acknowledgment

The authors would like to acknowledge the constant support provided by Director, ARCI throughout the course of this investigation and research funding from Boeing. Authors would like to thank A. Ramesh, J.V. Rao, B.S. Rao, G. Venkat Rao and K.S. Rao for the technical support and G.V.R. Reddy for the SEM data acquisition.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Subasri, R., Soma Raju, K.R.C., Reddy, D.S. et al. Environmentally friendly Zn–Al layered double hydroxide (LDH)-based sol–gel corrosion protection coatings on AA 2024-T3. J Coat Technol Res 16, 1447–1463 (2019). https://doi.org/10.1007/s11998-019-00229-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-019-00229-y