Abstract

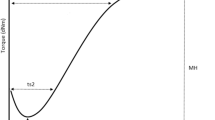

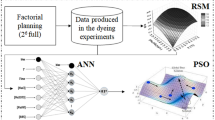

Alkyd resins are widely used in the paint industry and although they have a long history about 70–100 years, today the developments in alkyds are still welcome and innovations are still needed. Artificial neural network (ANN) and response surface methodology based on a 25−1 fractional factorial design were used as tools for simulation and optimization of the polycondensation process for autooxidative drying alkyd resin from palm kernel stearin: rubber seed oil blend of 70:30 ratio. A feed forward neural network model with Levenberg–Marquardt back propagation training algorithm was adapted to predict the responses (conversion Y 1, viscosity Y 2, and molecular weight average Y 3). The studied input variables were reaction time, temperature, catalyst concentration, oil ratio, and stirring rate. The performance of the RSM and ANN model showed adequate prediction of the responses in terms of the process factors, with MRPD of ±4.47% (Y 1), ±2.08% (Y 2), ±8.92% (Y 3) and ±6.50% (Y 1), ±3.31% (Y 2), ±10.20% (Y 3), respectively. The sensitivity analysis showed that while reaction time is the most effective process parameter, the interaction of the five process variables produced the most significant effect on the studied responses with the overall minimum MSE of 0.079. The optimization task performed using a genetic algorithm linked to the RSM model gave a viable, nondominated optimal response and optimum operating conditions regarding the route to high-quality resin at reduced material and operational costs. Overall, coupled RSM-GA was found to be a better tool for modeling and optimization of the alkyd resin production.

Similar content being viewed by others

References

Wicks, ZW, Jones, FN, Pappas, SP, Organic Coatings: Science and Technology, Vol. I. Wiley, New York (1994)

Http//: www.persistencemarketresearch.com/mediarelease/paints-coatings-market.asp

Challener, C, "Solving the Paint Price Puzzle." Painting and Wallcovering Contractor, pp. 24–29 (2009)

Pramanik, S, Sagak, K, Konwar, BK, Karak, N, “Synthesis, Characterization and Properties of a Castor Oil Modified Biodegradable Poly(Ester Amide) Resin.” Prog. Org. Coat., 75 (4) 569–578 (2012)

Azimi, ARN, Yahya, R, Gan, S-N, “Cleaner Production Through Using By-Product Palm Stearin to Synthesis Alkyd Resin for Coating Applications.” J. Clean. Prod., 54 307–314 (2013)

Uzoh, CF, Synthesis of Alkyd Resin from Some Inedible Non-drying Oil for Surface Coating Application, (2016). PhD Dissertation, Nnamdi Azikiwe University, Awka

Azimi, ARN, Yahya, R, Gan, S-N, “Investigating Effect of Conventional and Nano Zinc Pigments on Air-Drying Property of Palm-Stearin-Based Alkyd Resin Paints.” Int. J. Polym. Mater. Polym. Biomater., 62 (4) 199–202 (2013)

Azimi, ARN, Yahya, R, Gan, S-N, “Improving Coating Characteristics of Palm Stearin Alkyd by Modification with Ketone Resin.” Prog. Organ. Coat., 76 712–719 (2013)

Uzoh, CF, Onukwuli, OD, Odera, RS, Ofochebe, S, “Optimization of Polyesterification Process for Production of Palm Oil Modified Alkyd Resin Using Response Surface Methodology.” J. Environ. Chem. Eng., 1 777–785 (2013)

Box, GEP, Wilson, KG, “On the Experimental Attainment of Optimum Conditions.” J. R. Stat. Soc. B, 13 1 (1951)

Montgomery, DC, Design and Analysis of Experiments, 6th ed. Wiley, New York (2005)

Taguchi, G, Wu, Y, Introduction to Off-line Quality Control. Central Japan Quality Control Association, Nagoya (1980)

Taguchi, G, System of Experimental Design: Engineering Methods to Optimize Quality and Minimize Cost. UNIPUB, New York (1987)

Taguchi, G, Introduction to Quality Engineering. Asian Productivity Organization, UNIPUB, New York (1991)

Wagoner, R, Experimental Process Design. More head State University, Morehead (1998)

Babu, BV, Process Plant Simulation, pp. 257–290. Oxford University Press, New Delhi (2004)

Mandal, S, Sivaprasad, PV, Venugopal, S, Murthy, KPN, “Artificial Neural Network Modeling to Evaluate and Predict the Deformation Behavior of Stainless Steel Type AISI 304L During Hot Torsion.” Appl. Soft Comput., 9 237–244 (2009)

Bas, D, Boyaci, IH, “Modeling Optimization II: Comparison of Estimation Capabilities of Response Surface Methodology with Artificial Neural Networks in a Biochemical Reaction.” J. Food Eng., 78 846–854 (2007)

Kose, E, “Modelling of Colour Perception of Different Age Groups Using Artificial Neural Networks.” Expert Syst. Appl., 34 2129–2139 (2008)

Holland, JH, Adaptation in Natural and Artificial Systems. The University of Michigan Press, Michigan (1975)

Ghaffari, A, Abdollahi, H, Khoshayand, MR, Bozchalooi, IS, Dadgar, A, Rafiee-Tehrani, M, “Performance Comparison of Neural Network Training Algorithms in Modeling of Bimodal Drug Delivery.” Int. J. Pharm., 327 126–138 (2006)

Montgomery, DC, “Experimental Design for Products and Processes.” Statistician, 48 (2) 159–177 (1999)

Montgomery, DC, Design and Analysis of Experiments, 5th ed. Wiley, New York (2001)

Ghazanfari, M, Arkat, J, Neural Networks (Principles and Applications), Science and Industry University of Iran (2004)

Haeri, SM, Sadati, N, Mahin Rousta, R, Using Neural Network for Anticipating Tension Behavior, Strain of Clay, Set of Articles at 5th International Civil (2000)

Menkiti, MC, Onukwuli, OD, “Utilization Potentials of Rubber Seed Oil for the Production of Alkyd Resin Using Variable Base Oil Lengths.” N. Y. Sci. J., 4 (2) 51–58 (2011)

Gogte, BB, Dabhade, SB, “Alkyd Based on Non Edible Oils Karanja Oil (Pongamia glabra).” Paint India, 3–5 (1981)

Hlaing, NN, Mya, O, “Manufacture of Alkyd Resin from Castor Oil.” World Acad. Sci. Eng. Technol., 24 115–161 (2008)

Aigbodion, AI, Okieimen, FE, “Kinetics of the Preparation of Rubber Seed Oil Alkyds.” Eur. Polym. J., 32 1105–11081 (1996)

Igwe, IO, Ogbobe, O, “Studies on the Properties of Polyester and Polyester Blends of Selected Vegetable Oil.” J. Appl. Polym. Sci., 75 1441–1446 (2000)

Henerndez-Escoto, H, Lopez, T, Alvarez, J, “Estimation of Alkyd Reactors with Discrete-Delayed Measurements.” Chem. Eng. J., 160 698–707 (2010)

López, T, Hernández, H, Alvarez, J, “Robust nonlinear estimation of alkyd reactors with discrete-delayed measurements,” ADCHEM2000 Congress, Pisa, Italy (2000)

Hernández, H, Alvarez, J, “Robust Estimation of Continuous Nonlinear Plants with Discrete Measurements.” J. Process Control, 13 69–89 (2003)

Alvarez, J, Lopez, T, “Robust Dynamic State Estimation of Nonlinear Plants.” AIChE J., 45 (1) 107–123 (1999)

Fujita, H, Kishimoto, A, “Interpretation of Viscosity Data for Concentrated Polymer Solutions.” J. Chem. Phys., 34 393–398 (1961)

Katarina, MR, Jelena, MA, Petar, SM, Olivera, SS, “Optimization of Ultrasound-Assisted Base-Catalysed Methanolysis of Sunflower Oil Using Response Surface and Artificial Neural Network Methodology.” Chem. Eng. J., 2015–2016 82–89 (2013)

Manpreet, SB, Dhriti, K, Rajeev, KK, Akepati, SR, Ashwani, KT, “RSM and ANN Modeling for Electrocoagulation of Copper from Simulated Wastewater: Multi Objective Optimization Using Genetic Algorithm Approach.” Desalination, 274 74–80 (2011)

Pablo, CG, Hugo, DM, Alberto, AI, Alejandro, JB, Hector, CG, “Application of Response Surface Methodology and Artificial Neural Networks for Optimization of Recombinant Oryza sativa Non-symbiotic Hemoglobin 1 Production by Escherichia coli in Medium Containing Byproduct Glycerol.” Bioresour. Technol., 101 7537–7544 (2010)

Anna, W, Katarzyna, C, Daria, P, Anna, D, Karol, P, “Application Response Surface Methodology and Artificial Neural Network Methods in Modeling and Optimization of Biosorption Process.” Bioresour. Technol., (2014). doi:10.1016/j.biortech.2014.01.021

Sajjadi, B, Davoody, M, Abdul Aziz, AR, Ibrahim, S, “Analysis and Optimization of Ultrasound-Assisted Alkaline Palm Oil Transesterification by RSM and ANN-GA.” Chem. Eng. Commun., (2016). doi:10.1080/00986445.2015.1135427

Deb, K, Multi-Objective Optimization Using Evolutionary Algorithms. Wiley, New York (2001)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Uzoh, C.F., Onukwuli, O.D. Optimal prediction of PKS: RSO modified alkyd resin polycondensation process using discrete-delayed observations, ANN and RSM-GA techniques. J Coat Technol Res 14, 607–620 (2017). https://doi.org/10.1007/s11998-016-9881-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-016-9881-6