Abstract

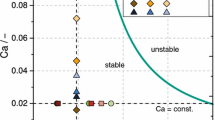

Paint films with uniform thicknesses ranging from 150 to 820 μm were applied on stainless steel substrates using a model paint consisting of a resin dissolved in butanol and the test samples were cured in a natural convection oven at a temperature of 140°C. Photographs of the paint surface were taken during drying, and the weight loss was measured. Cellular structures appeared on the paint surface, induced by surface tension-driven flows due to solvent concentration variations. For thin films (<500 µm), the patterns disappeared in a few minutes and the dried paint surface was smooth, while for thicker paint films, wave-like structures remained on the hardened paint layer, creating an uneven surface. An analytical solution of the mass-diffusion equation was used to model solvent evaporation from the paint film and to calculate the concentration gradient and surface tension variations in the paint films. In thin films, all the solvent was depleted, and surface tension gradients disappeared before curing was complete, allowing the surface to become smooth. In thicker films, concentration gradients that drove cellular flows persisted until the paint dried, leaving orange peel on the surface.

Similar content being viewed by others

Abbreviations

- t :

-

Time (s)

- T :

-

Temperature (°C)

- g :

-

Gravitational acceleration (m/s2)

- J :

-

Volatile mass flux (kg/m2s)

- L :

-

Paint film thickness (m)

- D v :

-

Volatile diffusivity in paint (m2/s)

- D a :

-

Volatile diffusivity in air (m2/s)

- k :

-

Thermal diffusivity (m2/s)

- x :

-

Vertical coordinate (m)

- α :

-

Mass transfer coefficient (kg/m2s)

- β :

-

Liquid thermal expansion coefficient (k−1)

- F σ :

-

Surface tension force (N/m)

- F μ :

-

Viscous shear force (N/m)

- M :

-

Mass (kg)

- C :

-

Concentration

- C i :

-

Initial volatile concentration

- C ∞ :

-

Volatile concentration above paint layer

- ∆C :

-

Concentration difference across the paint film

- Bi :

-

Biot number

- Fo :

-

Fourier number

- Ma :

-

Marangoni number

- \(\rho\) :

-

Model paint density (kg/m3)

- \(\rho_{\text{v}}\) :

-

Volatile partial density (kg/m3)

- µ :

-

Dynamic viscosity (N s/m2)

- σ :

-

Surface tension (N/m)

- λ n :

-

Eigenvalues

References

Kiegle-Böckler, G, “Specifications and Testing.” In: Streitberger, H-J, Dossel, K-F (eds.) Automotive Paints and Coatings, pp. 381–393. Wiley, Weinheim, 2008

ASTM E284, Standard Terminology of Appearance. ASTM International, West Conshohocken, PA

Bénard, H, “Les tourbillons cellulaires dans une liquid.” Gen. Schi Pures, 11 1261–1271 (1900)

Pearson, JRA, “On Convection Cells Induced by Surface Tension.” J. Fluid Mech., 4 489–500 (1958)

Block, MJ, “Surface Tension as the Cause of Benard Cells and Surface Deformation.” Nature, 178 650–651 (1956)

Koschmieder, EL, Biggerstaff, MI, “Onset of Surface-Tension-Driven Benard Convection.” J. Fluid Mech., 167 49–64 (1986)

Schatz, GP, Nietzel, MF, “Experiments on Thermocapillary Instabilities.” J. Fluid Mech., 33 93–127 (2001)

Koschmieder, EL, Prahl, SA, “Surface-Tension-Driven Benard Convection in Small Containers.” J. Fluid Mech., 215 571–583 (1990)

Dutton, TW, Pate, LR, Hollingsworth, DK, “Imaging of Surface-Tension-Driven Convection Using Liquid Crystal Thermography.” J. Heat Trans., 132 121601 (2010)

Cerisier, P, Rahal, S, Azuma, H, “Pattern Dynamic of the Bénard-Marangoni Instability in a Medium Aspect Ratio Container.” J. Phys., 64 012004 (2007)

Weh, L, “Surface Structures in Thin Polymer Layers Caused by Coupling in Diffusion-Controlled Marangoni Instability and Local Horizontal Temperature Gradient.” J. Macromol. Mater. Eng., 290 976–986 (2005)

Chai, AT, Zhang, N, “Experimental Study of Marangoni-Bénard Convection In a Liquid Layer Induced by Evaporation.” Exp. Heat Trans., 11 187–205 (1998)

Abbasian, A, Ghaffarian, SR, Mohammadi, N, Khosroshahi, MR, Fathollahi, M, “Study on Different Platforms of Paint’s Solvents and the Effect of Surfactants.” Prog. Org. Coat., 49 229–235 (2004)

Vinnichenko, N, Uvarov, A, Plaksina, Y, “Combined Study of Heat Exchange Near the Liquid-Gas Interface by Means of Background Oriented Shclieren and Infrared Thermal Imaging.” 8th World Conference on Experimental Heat Transfer, Fluid Mechanics, and Thermodynamics, 2013.

Hansen, M, Pierce, PE, “Cellular Convection in Polymer Coating—An Assessment.” Ind. Eng. Chem. Prod. Res. Develop., 12 (1) 67–70 (1973)

Köllner, T, Schwarzenberger, K, Eckert, K, Boeck, T, “Multiscale Structure in Solutal Marangoni Convection: Three-dimentional Simulations and Supporting Experiments.” Phys. Fluids, 25 092109 (2013)

Uguz, KE, Narayanan, R, “Instability in Evaporative Binary Mixtures. I. The Effect of Solutal Marangoni Convection.” Phys. Fluids, 24 094101 (2012)

Zhang, J, Oron, A, Behringer, RP, “Novel Pattern Forming States for Marangoni Convection in Volatile Binary Liquids.” Phys. Fluids, 23 0720102 (2011)

Harris, J, Lewis, JA, “Marangoni Effects on Evaporative Lithographic Patterning of Colloidal Films.” Langmuir, 24 (8) 3681–3685 (2008)

Chen, J, Yang, C, Mao, ZS, “The Interphase Mass Transfer in Liquid-Liquid Systems with Marangoni Effect.” Eur. Phys. J. Special Topics, 224 389–399 (2015)

Schwarzenberger, K, Kllner, T, Linde, H, Boeck, T, Odenbach, S, Eckert, K, “Pattern Formation and Mass Transfer under Stationary Solutal Marangoni Instability.” Adv Colloid Interface Sci., 206 344–371 (2014)

Kiil, S, “Quantification of Simultaneous Solvent Evaporation and Chemical Curing in Thermoset Coatings.” J. Coat. Technol. Res., 7 (5) 569–586 (2010)

Dušková-Smrčková, M, Dušek, K, “Processes and States During Polymer Film Formation by Simultaneous Crosslinking and Solvent Evaporation.” J. Mater. Sci., 37 4733–4741 (2002)

Cheever, GD, Ngo, P, “Effect of Substrate and Paint Layers on the Roughness and Appearance of a Silver Base Coat/Clear Coat System.” J. Coat. Technol., 61 (70) 65–71 (1989)

Peters, CA, Nichols, ME, Ellwood, KRJ, “The Evolution of Surface Texture in Automotive Coatings.” J. Coat. Technol. Res., 8 (4) 469–480 (2011)

Javaheri, H, M.Eng thesis, “Automotive Paint Properties,” Toronto, 2013.

Konieczny, J, Meyer, G, “Computer Rendering and Visual Detection of Orange Peel.” J. Coat. Technol. Res., 9 (3) 297–307 (2012)

Schneider, M, Frindi, S, Appearance Measurement by Wave-Scan DOI and Profilometry. Fraunhofer IPA, Stuttgart, 2004

Crank, J, The Mathematics of Diffusion. Oxford University Press, Oxford, 1975

Ion, L, Vergnaud, JM, “Process of Drying a Polymeric Paint by Diffusion-Evaporation and Shrinkage. Determination of the Concentration-Dependent Diffusivity.” J. Polym. Testing, 14 479–487 (1995)

Blandin, HP, David, JC, Vergnaud, JM, “Modeling of Drying of Coatings: Effect of the Thickness, Temperature and Concentration of Solvent.” Prog. Org. Coat., 15 163–172 (1987)

Long, FA, Richman, D, “Concentration Gradient for Diffusion of Vapors in Glassy Polymers and their Relation to Time Dependent Diffusion Phenomena.” J. Am. Chem. Soc., 82 (3) 513–519 (1960)

Carslaw, HS, Jaeger, JC, Conduction of Heat in Solids. Clarendon Press, Oxford, 1959

Vergnaud, JA, Drying of Polymeric and Solid Materials. Springer, London, 1992

Fujita, H, “Diffusion in Polymer-Dilute Systems.” Adv. Polym. Sci., 3 (1) 1–47 (1961)

Halley, PJ, Machay, ME, “Chemorheology of Thermosets-An Overview.” J. Polym. Eng. Sci., 36 (5) 593–609 (1996)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saranjam, N., Chandra, S., Mostaghimi, J. et al. Orange peel formation due to surface tension-driven flows within drying paint films. J Coat Technol Res 13, 413–426 (2016). https://doi.org/10.1007/s11998-015-9752-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-015-9752-6