Abstract

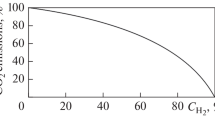

The atmosphere under the conditions of a coal combustion reaction in the furnace is the factor that makes the most significant difference during mode transition from traditional air to oxy-fuel combustion. The flue gas is adopted as the primary air and secondary air for pulverized-coal conveying and the support of combustion; it has a high carbon dioxide concentration during the oxy-fuel combustion. The air-leakage reduces CO2 enrichment and leads to thermal NO x production. A control strategy of this shift operation is conducted in a 35MW oxy-fuel combustion power plant boiler by adjusting the furnace pressure, regulating the recirculation rate of the flue gas and amending the oxygen concentration in the inlet stream. The furnace pressure can be changed smoothly and stabilized at a micro-positive level as the pressurized air flow is monitored at a suitable range. The combustion-supporting flue gas is modified by the oxygen content in the furnace outlet, and the circulation rate of the flue gas verifies the regulation process. Results show that the CO2 concentration in the flue gas can be rapidly increased along with the increment of furnace pressure and oxygen in the inlet stream; then, this procedure gradually becomes flattened. The CO2 content in the flue gas correlates with the recirculation rate of the flue gas and oxygen concentration in the inlet stream. The two operation parameters should be maintained at a high CO2 concentration in a range from 0.6-0.7 and 29.5%-30.5%, respectively. Sampling analysis shows that SO2 and NO x emissions were 26 (±1.5) mg/MJ and 90 (±11.7) mg/MJ in air condition, 14 (±0.4) mg/MJ and 34 (±1.6) mg/MJ in oxy-fuel combustion; the burnout rate, mechanical losses of incomplete combustion and the unburned carbon rate remained similar at these two stable combustion modes. This mode transition scheme should provide a reference for monitoring and diagnostics, design and operation control of an oxygen-enriched pulverized-coal combustion power plant boiler.

Similar content being viewed by others

References

T. Fujimori and T. Yamada, Proceedings of the Combustion Institute, 34(8), 2111 (2013).

F. Normann, K. Andersson, B. Leckner and F. Johnsson., Progress Energy Combustion Sci., 35(5), 385 (2009).

K. Kupila, P. Dernjatin, R. Sormunen, T. Sumida and K. Kiyama, A. Briglia, I. Sanchez-Molinero and A. Darde, Energy Procedia, 4, 1820 (2011).

L. Stromberg, G. Lindgren, J. Jacoby, R. Giering, M. Anheden, U. Burchhardt, H. Altmann, F. Kluger and G.-N. Stamatelopoulos, Energy Procedia, 1(1), 581 (2009).

M. Lupion, I. Alvarez, P. Otero, R. Kuivalainen, J. Lantto, A. Hotta and H. Hack, Energy Procedia, 37, 6179 (2013).

G. Scheffknecht, L. Al-Makhadmeh, U. Schnell and J. Maier, Int. J. Greenhouse Gas Control, 5(S1), S16 (2011).

R. C. da Silver, T. Kangwanpongpan and H. J. Krautz, Fuel, 115, 507 (2014).

B. J. P. Buhre, L. K. Elliott, C. D. Sheng, R. P. Gupta and T. F. Wall, Progress Energy Combustion Sci., 31(4), 283 (2005).

T. Wall, Y. Liu, C. Spero, L. Elliott, S. Khare, R. Rathnam, F. Zeenathal, B. Moghtaderi, B. Buhre, C. Sheng, R. Gupta, T. Yamada, K. Makino and J. Yu, Chem. Eng. Res. Design, 87(8), 1003 (2009).

K. Andersson, R. Johansson, S. Hjartstam, F. Johnsson and B. Leckner, Experimental Thermal and Fluid Science, 33(1), 67 (2008).

C. Lupianez, I. Guedea, I. Bolea, L. I. Díez and L. M. Romeo, Fuel Processing Technol., 106, 587 (2013).

B. Leckner and A. G. Barea, Appl. Energy, 125, 308 (2014).

Y. Tan, E. Croiset, M. A. Douglas and K. V. Thambimuthu, Fuel, 85(4), 507 (2005).

M. Pottmann, G. Engl, B. Stahl and R. Ritter, Energy Procedia, 4, 951 (2011).

D. Snarheim, Control Issues in Oxy-fuel Combustion, Norwegian Univ. of Sci. and Technol. (2009).

I. Guedea, I. Bolea, C. Lupianez, N. Cortés, E. Teruel, J. Pallarés, L. I. Díez and L. M. Romeo, Energy Procedia, 4, 972(2011).

K. J. Kuczynski, F. D. Fitzgerald, D. Adams, F. H. M. Glover, V. White, H. Chalmers, O. Errey and P. Stephenson, Energy Procedia, 4, 2541 (2011).

P. J. Edge, P. J. Heggs, M. Pourkashanian, P. L. Stephenson and A. Williams, Fuel, 101, 234 (2012).

B. Jin, H. Zhao and C. Zheng, Int. J. Greenhouse Gas Control, 30, 97 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

The paper will be reported in the 11th China-Korea Clean Energy Workshop.

Rights and permissions

About this article

Cite this article

Luo, Z., Cheng, W., Wu, B. et al. A mode transition strategy from air to oxyfuel combustion in a 35 MW coal-fired power plant boiler. Korean J. Chem. Eng. 34, 1554–1562 (2017). https://doi.org/10.1007/s11814-017-0046-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-017-0046-9