Abstract

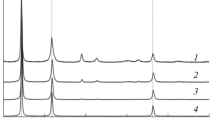

Particles in different states of oxidation were prepared by spray pyrolyses of aqueous solutions of silver and copper nitrates under different gas environments: air, nitrogen or mixture gas of 10 vol%H2-N2, respectively. Silver nitrate was converted to phase-pure silver at temperatures below 500 °C whose densification and crystallization were completed around 500 °C, irrespective of the gas environment. On the other hand, phase-pure copper(II) oxide was formed from copper nitrate up to 1,000 °C with air, but below 800 °C with nitrogen, above which copper(I) oxide was produced. Phase-pure copper particles were obtained with the mixture gas at temperatures above 400 °C. Copper(I) oxide was sintered and crystallized more easily than copper(II) oxide. The rates of the metallization, sintering and crystallization of copper were between those of silver and nickel.

Similar content being viewed by others

References

http://www.silverinstitute.org/, the Silver Institute, 45–55 (2004).

T. Addona, P. Auger, C. Celik and G. Chen, Nickel and copper powders for high capacitance MLCC manufacture, Passive Component Industry, Nov./Dec., 14–24 (1999).

T. T. Kodas and M. J. Hampden-Smith, Aerosol processing of materials, Wiley-VCH, 299–306 (1999).

T. T. Kodas, M. J. Hampden-Smith, J. Caruso, D. J. Skamser, Q. H. Powell and C. D. Chandler, Nickel powders, methods for producing powders and devices fabricated from same, U.S. Patent, 6316100 (2001).

K. Nagashima, M. Wada and A. Kato, J. Mater. Res., 5, 2828 (1990).

S. Stovic, I. Ilic and D. Uskokovic, Mater. Lett., 24, 369 (1995).

S. L. Che, K. Takada, K. Takashima, O. Sakurai, K. Shinozaki and N. Mizutani, J. Mater. Sci., 34, 1313 (1999).

D. J. Kang, S.G. Kim and H. S. Kim, J. Mater. Sci., 39, 5719 (2004).

K. N. Kim and S. G. Kim, Powder Technol., 145, 155 (2004).

T. C. Pluym, Q. H. Powell, A. S. Gurav, T. L. Ward, T. T. Kodas, L. M. Wang and H. D. Glickman, J. Aerosol Sci., 24, 383 (1993).

S. Y. Yang and S. G. Kim, Powder Technol., 146, 185 (2004).

I.W. Lenggoro, Y. Itoh, N. Iida and K. Okuyama, Mater. Res. Bull., 38, 1819 (2003).

D. J. Kang, Ph.D. Dissertation, Chung Ang University, Seoul (2003).

D. Majumdar, T. A. Shefelbine and T. T. Kodas, J. Mater. Res., 11, 2861 (1998).

N. Ichinose, Y. Osaki and S. Kashu, Introduction to Ultrafine Particle Technology (in Jap), Ohm Co, 29 (1988).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, E.K., Rah, S. & Kim, SG. Effect of gas environment on properties of particles prepared by spray pyrolysis of metal nitrates. Korean J. Chem. Eng. 25, 885–891 (2008). https://doi.org/10.1007/s11814-008-0146-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-008-0146-7