Abstract

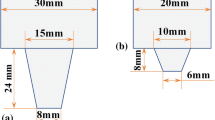

Fatigue is undoubtedly the most important design criterion in aeronautic structures. Although friction stir-welded joints are characterized by a high mechanical performance, they can enclose some defects, especially in their root. These defects along with the relatively low residual stresses of the friction stir-welding thermomechanical cycle can turn into primary sources of crack initiation. In this context, this article deals with the fatigue behavior of friction stir-welded joints subjected to surface smoothing by grinding improvement technique. The 4-mm-thick aluminum alloy 2024-T351 was used in this study. The fatigue strength of the base material, joints in the as-welded condition, and the sound and defective friction stir-welded joints improved by grinding were investigated in detail. The tests were carried out with a constant amplitude loading and with a stress ratio of R = 0. The fatigue results show that an improvement in fatigue behavior was obtained in the joints repaired by superficial grinding technique. The weld grinding technique is better especially for lower loads and increases the high cycle fatigue strength. The fatigue strength of the improved welded joints was higher than that of the base material.

Similar content being viewed by others

References

ESAB, Focus Aluminum, Svetsaren, 2000, 54(2), p 3–5

P.F. Mendez, New Trends in Welding in the Aeronautic Industry, Proceedings of the conference New Trends for the Manufacturing in the Aeronautic Industry, San Sebastian, Spain, May 24-25, 2000, p 21–38

P. Vilaça and L. Quintino, Soldadura por Fricção Linear – O Que a Indústria Portuguesa Precisa e Precisa de Saber, Tecnologia e Qualidade, Revista do ISQ, 2000, 38, p 46–57

W. Thomas, E. Nicholas, and S. Kallee, Friction Based Technologies For Joining and Processing. Friction Stir Welding and Processing, TMS Fall Meeting-Friction Stir Welding and Processing, Indianapolis, USA, 2001, p 3–13

C. Dawes and W. Thomas, Friction Stir Joining of Aluminium Alloys, TWI, Bull., 1995, 6, p 124–127

C. Dawes and W. Thomas, Friction Stir Process Welds Aluminium Alloys, Weld. J., 1996, 75, p 41–45

B. Bhat, R. Carter, R. Ding, K. Lawless, A. Nunes, C. Russel, and S. Shah, Friction Stir Welding Development at NASA-Marshall Space Flight Center, TMS Fall Meeting-Friction Stir Welding and Processing, Indianapolis, USA, 2001, p 117–128

G.E. Shepherd, The Potential for using Solid Phase Welding to Repair Cracks that may occur on Thin Aluminium Aircraft Wing Structure, 2nd International Symposium on FSW, Gothenburg, Sweden, 2000

J. Mononen, M. Sirén, and H. Hänninen, Cost Comparison of FSW and MIG Welded Aluminium Panels, 3rd International Symposium on Friction Stir Welding, Port Island, Kobe, Japan, 2001

P. Vilaça, Fundamentos do Processo de Soldadura por Fricção Linear: Análise Experimental e Modelação Analítica, Ph.D. thesis, Instituto Superior Técnico, Universidade Técnica de Lisboa, Setembro, 2003

S. Lomolino, R. Tovo, J. dos Santos, and D. Lohwasser, Fatigue strength of sound and defective friction stir welds on Al-Alloys for Airframes, 9th International Fatigue Congress, Atlanta, USA, 14-19 May, 2006

P. Cavaliere, R. Nobile, F.W. Panella, and A. Squillace, Mechanical and microstructural behaviour of 2024-7075 aluminium alloy sheets joined by friction stir welding, Int. J. Mach. Tools Manuf, 2006, 46, p 588–594

D. Fersini and A. Pirondi, Fatigue behaviour of Al2024-T3 friction stir welded lap joints, Eng. Fract. Mech., 2007, 74, p 468–480

L. Fratini, S. Pasta, and A.P. Reynolds, Fatigue Crack Growth in 2024-T351 Friction Stir Welded Joints: Longitudinal Residual Stress and Microstructural Effects, Int. J. Fatigue, 2009, 31, p 495–500

P. Cavaliere and F. Panella, Effect of tool position on the fatigue properties of dissimilar 2024-7075 sheets joined by friction stir welding, J. Mater. Process. Technol., 2008, 206, p 249–255

S. Lomolino, R. Tovo, and J. dos Santos, On the Fatigue Behaviour and Design Curves of Friction Stir Butt-Welded Al Alloys, Int. J. Fatigue, 2005, 27(3), p 305–316

T. Santos, P. Vilaça, and L. Quintino, Developments in NDT for Detecting Imperfections in Friction Stir Welds in Aluminium Alloys, Weld. World, 2008, 52, p 30–37

D. Bowness and M.M.K. Lee, Weld Toe Magnification Factors for Semi-Elliptical Cracks in T-Butt Joints: Comparation with Existing Solutions, Int. J. Fatigue, 2000, 22(5), p 389–396

J.C. Newman and I.S. Raju, An Empirical Stress-Intensity Factor Equation for the Surface Crack, Eng. Fract. Mech., 1981, 15(1/2), p 185–192

O. Hatamleh, J. Lyons, and R. Forman, Laser and Shot Peening Effects on Fatigue Crack Growth in Friction Stir Welded 7075-T7351 Aluminum Alloy Joints, Int. J. Fatigue, 2007, 29, p 421–434

Y.K. Gao, Improvement of Fatigue Property in 7050-T7451 Aluminum Alloy by Laser Peening and Shot Peening, Mater. Sci. Eng. A, 2011, 528, p 3823–3828

O. Hatamleh, A Comprehensive Investigation on the Effects of Laser and Shot Peening on Fatigue Crack Growth in Friction Stir Welded AA 2195 Joints, Int. J. Fatigue, 2009, 31, p 974–988

J.K.N. Murthy, D.S. Rao, and B. Venkataraman, Effect of Grinding on the Erosion Behaviour of a WC-Co-Cr Coating Deposited by HVOF and Detonation Gun Spray Processes, Wear, 2001, 249, p 592–600

B. Rajasekaran, S. Ganesh Sundara Raman, S.V. Joshi, and G. Sundararajan, Effect of Grinding on Plain Fatigue and Fretting Fatigue Behaviour of Detonation Gun Sprayed Cu-Ni-In Coating on Al-Mg-Si Alloy, Int. J. Fatigue, 2009, 31, p 791–796

R. Baptista, V. Infante, and C.M. Branco, Study of the Fatigue Behavior in Welded Joints of Stainless Steels Treated by Weld Toe Grinding and Subjected to Salt Water Corrosion, Int. J. Fatigue, 2008, 30, p 453–462

C. Vidal and V. Infante, Optimization of FS Welding Parameters for Improving Mechanical Behavior of AA2024-T351 Joints Based on Taguchi Method, J. Mater. Eng. Perform., 2013, 22(8), p 2261–2270

P. Haagensen and S.J. Maddox, IIW recommendations for weld toe improvement techniques, Commission XIII, International Institute of Welding, July, 2001

F. Nascimento, T. Santos, P. Vilaça, R.M. Miranda, and L. Quintino, Microstructural Modification and Ductility Enhancement of Surfaces Modified by FSP in Aluminium Alloys, Mater. Sci. Eng. A, 2009, 506, p 16–22

Acknowledgments

The authors would like to acknowledge the financial support from the Portuguese Foundation for the Science and Technology (FCT) through the PhD scholarship FCT SFRH/BD/62963/2009, and the material supplied by the OGMA – Indústria Aeronáutica de Portugal S.A., a specialist aviation company since 1918.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vidal, C., Infante, V. Fatigue Behavior of Friction Stir-Welded Joints Repaired by Grinding. J. of Materi Eng and Perform 23, 1340–1349 (2014). https://doi.org/10.1007/s11665-014-0875-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-0875-1