Abstract

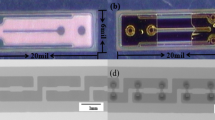

The microstructure evolution and shear behavior of the solder joints for the flip-chip light-emitting diode on the electroless nickel/immersion gold (ENIG) substrate were investigated in this study. The experimental results reveal that the solder joints for the anode and cathode have different microstructures and failure characteristics during the shear test before and after isothermal aging. For the solder joints for the anode, the interfacial intermetallic compound (IMC) is (Au, Ni)Sn4 at the solder/anode interface but dendritic Ni3Sn4 grains at the solder/ENIG interface after reflow. Meanwhile, the dendritic Ni3Sn4 grains are surrounded by (Au, Ni)Sn4, which suppresses the growth of the Ni3Sn4 grains during aging. For the solder joints for the cathode, a nano scaled Au-rich layer can be observed near the cathode/solder layer interface after reflow. And the Au-rich layer moves toward the bulk solder because of the volume expansion by the transformation from Au into (Au, Ni)Sn4 during reflow and isothermal aging. Due to the diffusion of the Au atom from the Au-rich layer into the bulk solder, the Au-rich layer transformed into an interface inside of the solder joint. The average shear force of the solder joints shows a decrease from 380 gf to 250 gf because of the microstructure evolution during the isothermal aging for 1000 h at 85°C. After long time aging, the primary failure mode of the solder joint for the anode changed from the anode broken to the brittle failure of the solder layer. The delamination between the IMC layer and the insulation layer is suggested to be the dominated failure mode of the solder joint for the cathode after aging.

Similar content being viewed by others

References

M.Y. Tsai, C.Y. Tang, C.Y. Yen, and L.B. Chang, IEEE Trans. Device Mater. Reliab. 14, 161 (2014).

Y. Liu, S.Y.Y. Leung, J. Zhao, K.Y.W. Cell, C.A. Yuan, G.Q. Zhang, F.L. Sun, and L.L. Luo, Microelectron. Reliab. 54, 2028 (2014).

K.C. Shen, W.Y. Lin, D.S. Wuu, S.Y. Huang, K.S. Wen, S.F. Pai, L.W. Wu, and R.H. Horng, IEEE Electron Device Lett. 34, 274 (2013).

R.H. Horng, S.H. Chuang, C.H. Tien, S.C. Lin, and D.S. Wuu, Opt. Express 22, A941 (2014).

M.J. Jeng, K.L. Chiang, H.Y. Chang, C.Y. Yen, C.C. Lin, Y.H. Chang, M.J. Lai, Y.L. Lee, and L.B. Chang, Microelectron. Reliab. 52, 884 (2012).

T. Chung, J.H. Jhang, J.S. Chen, Y.C. Lo, G.H. Ho, M.L. Wu, and C.C. Sun, Microelectron. Reliab. 52, 872 (2012).

Z. Li, Y. Tang, X. Ding, C. Li, D. Yuan, and Y. Lu, Appl. Therm. Eng. 65, 236 (2014).

H.H. Wu, K.H. Lin, and S.T. Lin, Microelectron. J. 43, 280 (2012).

Y. Li and C.P. Wong, Mater. Sci. Eng. R 5, 11 (2006).

J.W. Kim, Y.C. Lee, and S.B. Jung, J. Electron. Mater. 37, 9 (2008).

S.J. Wu, H.C. Hsu, S.L. Fu, and J.N. Yeh, Electron. Mater. Lett. 10, 497 (2014).

C.P. Wang, T.T. Chen, H.K. Fu, T.L. Chang, P.T. Chou, and I.E.E.E. Trans, Electron Devices 60, 1668 (2013).

U. Lafont, H. Zeijl, and S. Zwaag, Microelectron. Reliab. 52, 71 (2012).

M. Kong, S. Jeon, C. Hwang, and Y.C. Lee, J. Electron. Packag. 134, 021002 (2012).

O. Krammer, Microelectron. Reliab. 54, 457 (2014).

S.Q. Gao and Y.H. Zhou, Microelectron. Reliab. 53, 1137 (2013).

Y. Liu, F.L. Sun, H. Zhang, and P. Zou, J. Mater. Sci. 23, 1705 (2012).

G.K. Sujan, A. Haseeb, and A.B.M. Afifi, Mater. Charact. 97, 199 (2014).

Y. Liu, J. Zhao, C.A. Yuan, and F.L. Sun, IEEE Trans. Compon. Packag. Manuf. Technol. 4, 1754 (2014).

J. Chen, J. Shen, W. Xie, and H. Liu, J. Mater. Sci. 22, 1703 (2011).

C.E. Ho, R. Zheng, G.L. Luo, A.H. Lin, and C.R. Kao, J. Electron. Mater. 29, 1175 (2000).

W.L. Shih, T.L. Yang, H.Y. Chuang, M.S. Kuo, and C.R. Kao, J. Electron. Mater. 43, 4262 (2014).

M. Powers, J. Pan, J. Silk, and P. Hyland, J. Electron. Mater. 41, 224 (2012).

J.W. Yoon, H.S. Chun, and S.B. Jung, Mater. Sci. Eng. A 483, 731 (2008).

C. Fuchs, T. Schreck, and M. Kaloudis, J. Mater. Sci. 47, 4036 (2012).

P. Premchander and Y.T. Lee, Asian J. Chem. 25, S482 (2013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Sun, F., Luo, L. et al. Microstructure Evolution and Shear Behavior of the Solder Joints for Flip-Chip LED on ENIG Substrate. J. Electron. Mater. 44, 2450–2457 (2015). https://doi.org/10.1007/s11664-015-3774-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-015-3774-9