Abstract

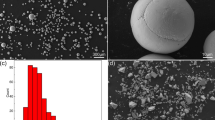

Liquid phase sintering behavior of 90W-6Ni-4Mn heavy alloy has been studied. The present work takes into account the thermodynamic oxidation/reduction reactions of the constituent elements W, Ni, and Mn. The sintering cycle consists of heating under high purity nitrogen gas, holding at reduction temperatures after the atmosphere is changed to dry hydrogen, and sintering at 1260 °C for 1 hour. As the reduction temperature increases from 1050 °C to 1200 °C, the relative sintered density increases from 92 pct, reaching 100 pct at temperatures above 1150 °C. The relative density increases with increasing holding time at the reduction temperature and remains unchanged with heating rate. The sintered microstructure has been analyzed by a scanning electron microscope and energy dispersive X-ray spectroscopy. The relative density was compared with those obtained from other investigators. It is found that the formation of manganese oxide due to reducing reactions of W and Ni powders should be avoided in order to obtain a W-Ni-Mn heavy alloy without pores.

Similar content being viewed by others

References

L.S. Magness, Jr.: Proc. 1st Int. Conf. on Tungsten and Tungsten Alloys, A. Bose and R.J. Dowding, eds., MPIF, New Jersey, 1992, pp. 15–22.

J. Lankford, A. Bose, and H. Couque: High Strain Rate Behavior of Refractory Metals and Alloys, R. Asfahani, E. Chen, and A. Crowson, eds., TMS, Pennsylvania, 1991, pp. 267–87.

U.S. Lindholm and G.R. Johnson: in Material Behavior under High Stress and Ultrahigh Loading Rates, J. Mescall and V. Weiss, eds., Plenum Press, New York, NY, 1983, pp. 61–79.

A. Belhadjhamida and R.M. German: Proc. 1st Int. Conf. on Tungsten and Tungsten Alloys, A. Bose and R.J. Dowding, eds., MPIF, New Jersey, 1992, pp. 195–204.

A. Belhadjhamida and R.M. German: Proc. Powder Metallurgy World Congress, J.M. Capus and R.M. German, eds., MPIF, New Jersey, 1992, vol. 3, pp. 47–55.

I. Barin and O. Knacke: Thermomechanical Properties of Inorganic Substances, Springer-Verlag, Berlin, and Verlag Stahleisen m.b.H., Düsseldorf, 1973, pp. VIII-XVIII, 295, 470, 578, and 863.

H.S. Nayer: Metals Handbook, 9th ed., vol. 7, Powder Metallurgy, ASM, Metals Park, OH, 1984, pp. 339–59.

T.B. Massalski, J.L. Murray, L.H. Bennett, and H. Baker: Binary Alloy Phase Diagrams, ASM, Metals Park, OH, 1986, vol. 2, p. 1573.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Hong, MH., Noh, JW., Kim, EP. et al. A study on the improvement of the sintered density of W-Ni-Mn heavy alloy. Metall Mater Trans B 28, 835–839 (1997). https://doi.org/10.1007/s11663-997-0011-9

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-997-0011-9