Abstract

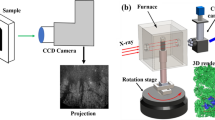

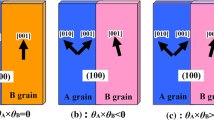

Upon solidification, most metallic alloys form dendritic structures that grow along directions corresponding to low index crystal axes, e.g., \(\langle100\rangle\) directions in fcc aluminum. However, recent findings[1,2] have shown that an increase in the zinc content in Al-Zn alloys continuously changes the dendrite growth direction from \(\langle100\rangle\) to \(\langle110\rangle\) in {100} planes. At intermediate compositions, between 25 wt pct and 55 wt pct Zn, \(\langle320\rangle\) dendrites and textured seaweeds were reported. The reason for this dendrite orientation transition is that this system exhibits a large solubility of zinc, a hexagonal metal, in the primary fcc aluminum phase, thus modifying its weak solid–liquid interfacial energy anisotropy. Owing to the complexity of the phenomenology, there is still no satisfactory theory that predicts all the observed microstructures. The current study is thus aimed at better understanding the formation of these structures. This is provided by the access to their 3D morphologies via synchrotron-based X-ray tomographic microscopy of quenched Bridgman solidified specimens in combination with the determination of the crystal orientation of the dendrites by electron-backscattered diffraction. Most interestingly, all alloys with intermediate compositions were shown to grow as seaweeds, constrained to grow mostly in a (001) symmetry plane, by an alternating growth direction mechanism. Thus, these structures are far from random and are considered less hierarchically ordered than common dendrites.

Similar content being viewed by others

Notes

in a system with also a smaller partition coefficient and a higher liquidus slope compared with Al-Zn

References

F. Gonzales and M. Rappaz: Metall. Mater. Trans. A, 2006, vol. 37, pp. 2797–2806.

F. Gonzales and M. Rappaz: Metall. Mater. Trans. A, 2008, vol. 39, pp. 2148–60.

S. Liu, R.E. Napolitano, and R. Trivedi: Acta. Mater., vol. 49, pp. 4271–76.

S. Henry, T. Minghetti, and M. Rappaz: Acta. Mater., 1998, vol. 46, pp. 6431–43.

A. Semoroz, Y. Durandet, and M. Rappaz: Acta. Mater., 2001, vol. 49, pp. 529–41.

T. Haxhimali, A. Karma, F. Gonzales, and M. Rappaz: Nat. Mater., 2006, vol. 5, pp. 660–64.

E. Brener, H. Müller-Krumbhaar, and D. Temkin: Phys. Rev. E, 1996, vol. 54, pp. 2714–22.

E. Brener, T. Ihle, H. Müller-Krumbhaar, Y. Saito, and K. Shiraishi: Physica A, 1994, vol. 204, pp. 96–110.

H. Emmerich, D. Schleussner, T. Ihle, and K. Kassner: J. Phys., 1999, vol. 11, pp. 8981–93.

S. Akamatsu, G. Faivre, T. Ihle: Phys. Rev. E, 1995, vol. 51, pp. 4751–80.

S. Akamatsu and G. Faivre G.: Phys. Rev. E, 1998, vol. 58, pp. 3302–15.

A.M. Mullis, K.I. Dragnevski, and R.F. Cochrane: Mater. Sci. Eng. A, 2004, vol. 375–377, pp. 157–62.

H. Assadi, M. Oghabi, D.M. Herlach: Acta. Mater., 2009, vol. 57, pp. 1639–47.

F. Gonzales. Ph.D. Thesis, Ecole Polytechnique Fédérale de Lausanne (2009).

J.A. Dantzig, P. Di Napoli, J. Friedli, and M. Rappaz: Metall. Mater. Trans. A, 2013. DOI: 10.1007/s11661-013-1911-8.

M. Stampanoni, A. Groso, A. Isenegger, G. Mikuljan, Q. Chen, A. Bertrand, S. Henein, R. Betemps, U. Frommherz, P. Böhler, D. Meister, M. Lange, and R. Abela: in Proc SPIE 6318 U. Bonse, ed., 2006, 63180M.

C. Hintermüller, F. Marone, A. Isenegger, and M. Stampanoni: J. Synchrotron. Radiat., 2010, vol. 17, pp. 550–59.

F. Marone and M. Stampanoni: J. Synchrotron. Radiat., 2012, vol. 19, pp. 1029–37.

M.E. Glicksman: Mater. Sci. Eng., 1984, vol. 65, pp. 45–55.

M. Rappaz and E. Blank: J. Cryst. Growth, 1986, vol. 74, pp. 67–76.

M.E. Glicksman and N.B. Singh: J. Cryst. Growth, 1989, vol. 98, pp. 277–84.

J. Friedli, J. Fife, P. Di Napoli, and M. Rappaz: in Proc MCWASP A. Ludwig, ed., 2012.

J. Fife, M. Rappaz, M. Pistone, T. Celcer, G. Mikuljan, and M. Stampanoni: J. Synchrotron. Radiat., 2012, vol. 19, pp. 352–58.

Acknowledgments

The authors gratefully acknowledge the financial support of the Fonds National Suisse pour la recherche scientifique (Grant No 200020-113260 and 121598), of the Swiss Competence Centre for Materials Science and Technology (CCMX), as well as the financial and technical support from the Paul Scherrer Institute. They would also like to thank Sam MacDonald and André Phillion for their previous assistance during the X-ray tomographic microscopy sessions at the Swiss Light Source. All electron microscopy measurements were obtained at the Centre Interdisciplinaire de Microscopie Electronique (CIME) of the Ecole Polytechnique Fédérale de Lausanne (EPFL).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 27, 2013.

Rights and permissions

About this article

Cite this article

Friedli, J., Fife, J.L., Di Napoli, P. et al. Dendritic Growth Morphologies in Al-Zn Alloys—Part I: X-ray Tomographic Microscopy. Metall Mater Trans A 44, 5522–5531 (2013). https://doi.org/10.1007/s11661-013-1912-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1912-7