Abstract

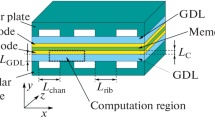

Protonic ceramic fuel cell (PCFC) has attracted more and more research attention due to its special working features, compared with both the traditional oxygen ionic solid oxide fuel cell (O2−-SOFC) and protonic exchange membrane fuel cell (PEMFC). The 3D CFD numerical method is generally considered to be an effective path to explore the proper air flow path design for the PCFC stack. In this paper, the 3D large-scale CFD models for the 25-cell PCFC stacks with both U-type and Z-type air flow paths and O2−-SOFC stack are developed to compare and access the flow and species distribution features within the PCFC stacks. The result shows that the U-type configuration would be a more proper choice for the PCFC air flow path to achieve higher air and oxygen feeding qualities than that of the Z-type configuration. The flow and species uniformities within the 25-cell PCFC stack are worse than that of the O2−-SOFC stack because the vapors are generated within the cathode side. Different vapor generation sites and operation temperatures are two key factors contributing to the different item distributing features within the PCFC and traditional O2−-SOFC stacks.

Similar content being viewed by others

References

Hu Z, Xu L, Li J, Gan Q, Xu X, Song Z, Shao Y, Ouyang M (2019) A novel diagnostic methodology for fuel cell stack health: performance, consistency and uniformity. Energy Convers Manage 185:611–621

Giacoppo G, Hovland S, Barbera O (2019) 2 kW Modular PEM fuel cell stack for space applications: development and test for operation under relevant conditions. Appl Energy 242:1683–1696

Forysinski P, Oloman C, Kazemi S, Nickchi T, Usgaocar A (2019) Development and use of a mixed-reactant fuel cell. J Power Sources 414:366–376

Chen D, Bi W, Kong W, Lin Z (2010) Combined micro-scale and macro-scale modeling of the composite electrode of a solid oxide fuel cell. J Power Sources 195(19):6598–6610

Zhao J, Jian Q, Huang Z, Luo L, Huang B (2019) Experimental study on water management improvement of proton exchange membrane fuel cells with dead-ended anode by periodically supplying fuel from anode outlet. J Power Sources 435:226775

Russner N, Dierickx S, Weber A, Reimert R, Ivers-Tiffée E (2020) Multiphysical modelling of planar solid oxide fuel cell stack layers. J Power Sources 451:227552

Yang G, Su C, Shi H, Zhu Y, Song Y, Zhou W, Shao Z (2020) Toward reducing the operation temperature of solid oxide fuel cells: our past 15 years of efforts in cathode development. Energy Fuels 34(12):15169–15194

Yuan T, Wu X, Bae SJ, Zhu X (2019) Reliability assessment of a continuous-state fuel cell stack system with multiple degrading components. Reliab Eng Syst Saf 189:157–164

Wu X, Yang D, Wang J, Li X (2019) Temperature gradient control of a solid oxide fuel cell stack. J Power Sources 414:345–353

Medvedev D (2019) Trends in research and development of protonic ceramic electrolysis cells. Int J Hydrogen Energy 44(49):26711–26740

Shin E-K, Anggia E, Parveen AS, Park J-S (2019) Optimization of the protonic ceramic composition in composite electrodes for high-performance protonic ceramic fuel cells. Int J Hydrogen Energy 44(59):31323–31332

Li K, Araki T, Kawamura T, Ota A, Okuyama Y (2020) Numerical analysis of current efficiency distributions in a protonic ceramic fuel cell using Nernst-Planck-Poisson model. Int J Hydrogen Energy 45(58):34139–34149

Wang N, Hinokuma S, Ina T, Zhu C, Habazaki H, Aoki Y (2020) Mixed proton–electron–oxide ion triple conducting manganite as an efficient cobalt-free cathode for protonic ceramic fuel cells. Journal of Materials Chemistry A 8(21):11043–11055

Zhang Q, Guo Y, Ding J, Jiang G, Wen J (2020) Comprehensive models for evaluating electrolyte hole conductivity and its impacts on the protonic ceramic fuel cell. J Power Sources 472:228232

Hwang SH, Kim SK, Nam J-T, Park J-S (2021) Fabrication of an electrolyte-supported protonic ceramic fuel cell with nano-sized powders of Ni-composite anode. Int J Hydrogen Energy 46(1):1076–1084

Le LQ, Hernandez CH, Rodriguez MH, Zhu L, Duan C, Ding H, O’Hayre RP, Sullivan NP (2021) Proton-conducting ceramic fuel cells: scale up and stack integration. J Power Sources 482:228868

Chen D, Xu Y, Tade MO, Shao Z (2017) General regulation of air flow distribution characteristics within planar solid oxide fuel cell stacks. ACS Energy Lett 2(2):319–326

Kwan TH, Wu X, Yao Q (2019) Performance comparison of several heat pump technologies for fuel cell micro-CHP integration using a multi-objective optimisation approach. Appl Therm Eng 160:114002

Chen D, Zhang Q, Lu L, Periasamy V, Tade MO, Shao Z (2016) Multi scale and physics models for intermediate and low temperatures H+-solid oxide fuel cells with H+/e−/O2− mixed conducting properties: part A, generalized percolation theory for LSCF-SDC-BZCY 3-component cathodes. J Power Sources 303:305–316

Zhu Z, Wang S (2019) Investigation on samarium and yttrium co-doping barium zirconate proton conductors for protonic ceramic fuel cells. Ceram Int 45(15):19289–19296

Chen D, Xu Y, Hu B, Yan C, Lu L (2018) Investigation of proper external air flow path for tubular fuel cell stacks with an anode support feature. Energy Convers Manage 171:807–814

Chen D, Zeng Q, Su S, Bi W, Ren Z (2013) Geometric optimization of a 10-cell modular planar solid oxide fuel cell stack manifold. Appl Energy 112:1100–1107

Fang Q, Blum L, Peters R, Peksen M, Batfalsky P, Stolten D (2015) SOFC stack performance under high fuel utilization. Int J Hydrogen Energy 40(2):1128–1136

Su S, He H, Chen D, Zhu W, Wu Y, Kong W, Wang B, Lu L (2015) Flow distribution analyzing for the solid oxide fuel cell short stacks with rectangular and discrete cylindrical rib configurations. Int J Hydrogen Energy 40(1):577–592

Jiang C, Gu Y, Guan W, Ni M, Sang J, Zhong Z, Singhal SC (2020) Thermal stress analysis of solid oxide fuel cell with Z-type and serpentine-type channels considering pressure drop. J Electrochem Soc 167(4):044517

Albrecht KJ, Dubois A, Ferguson K, Duan C, O’Hayre RP, Braun RJ (2019) Steady-state and dynamic modeling of intermediate-temperature protonic ceramic fuel cells. J Electrochem Soc 166(10):F687–F700

Chen D, Ding K, Chen Z, Wei T, Liu K (2018) Physics field distributions within fuel cell stacks with manifolds penetrating through the plane zone and open outlet features. Energy Convers Manage 178:190–199

Bi W, Chen D, Lin Z (2009) A key geometric parameter for the flow uniformity in planar solid oxide fuel cell stacks. Int J Hydrogen Energy 34(9):3873–3884

Lin B, Shi Y, Cai N (2017) Numerical simulation of cell-to-cell performance variation within a syngas-fuelled planar solid oxide fuel cell stack. Appl Therm Eng 114:653–662

Chen D, Wang H, Zhang S, Tade MO, Shao Z, Chen H (2015) Multiscale model for solid oxide fuel cell with electrode containing mixed conducting material. AIChE J 61(11):3786–3803

Chen D, Xu Y, Tade MO, Shao Z (2017) General regulation of air flow distribution characteristics within planar solid oxide fuel cell stacks. ACS Energy Lett 2:319–326

Ding K, Zhu M, Han Z, Kochetov V, Lu L, Chen D (2020) Momentum-species-heat-electrochemistry distribution characteristics within solid oxide fuel cell stack with complex inter-digital fuel channels. Ionics 26(9):4567–4578

Lin B, Shi Y, Ni M, Cai N (2015) Numerical investigation on impacts on fuel velocity distribution nonuniformity among solid oxide fuel cell unit channels. Int J Hydrogen Energy 40(7):3035–3047

Acknowledgements

This research was funded by the financial support of the Ministry of Science and Technology of the People’s Republic of China (CU03-10), Jiangsu ‘333’ High Level Talents Project and Jiangsu Education Department (1154702001-1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dai, J.Q., Yang, Z.M., Wang, W.S. et al. Study the flow and species distribution characteristics in a typical 25-cell proton ceramic fuel cell stack by 3D large-scale modeling. Ionics 28, 1863–1872 (2022). https://doi.org/10.1007/s11581-022-04465-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-022-04465-y