Abstract

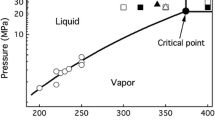

Microcrystalline cellulose (avicel) is treated in hot-compressed aprotic solvents, sulfolane and 1,4-dioxane, using a batch-type reaction system with a molten tin bath in a range from 290 to 390°C. The corresponding densities of the solvent are 0.25–1.26 g/cm3 and 0.21–1.03 g/cm3 for sulfolane and 1,4-dioxane, respectively. As a result, in both solvents, more than 90% of cellulose is found to be decomposed to the solvent-soluble portion in which levoglucosan is the main component with the highest yield of about 35% on original cellulose basis. The decomposition rate to levoglucosan is, however, faster in sulfolane than in 1,4-dioxane, while levoglucosan is more stable in 1,4-dioxane. In addition, its yield is found to be solvent-density dependent to be highest around 0.4–0.5 g/cm3 for both solvents. To elucidate these decomposition behaviors, the results obtained in this study with aprotic solvents are compared with protic solvents such as water and methanol in previous works.

Similar content being viewed by others

References

Shafizadeh F, Fu Y L. Pyrolysis of cellulose. Carbohy Res, 1973, 29: 113–122

Shafizadeh F. Introduction to pyrolysis of biomass. J Anal Appl Pyrolysis, 1982, 3: 283–305

Shafizadeh F, Furneaux R H, Cochran T G, Scholl J P, Sakai Y. Production of levoglucosan and glucose from pyrolysis of cellulosic materials. J Appl Poly Sci, 1979, 23: 3525–3539

Kwon G-J, Kim D-Y, Kimura S, Kuga S. Rapid-cooling, continuous-feed pyrolyzer for biomass processing Preparation of levoglucosan from cellulose and starch. J Anal Appl Pyrolysis, 2007, 80: 1–5

Dobele G, Rossinskaja G, Dizhbite T, Telysheva G, Meier D, Faix O. Application of catalysts for obtaining 1,6-anhydrosacchadides from cellulose and wood by fast pyrolysis. J Anal Appl Pyrolysis, 2005, 74: 401–405

Piskorz J, Majerski P, Radlein D, Vladars-Usas A, Scott D S. Flash pyrolysis of cellulose for production of anhydro-oligomers. J Anal Appl Pyrolysis, 2000, 56: 145–166

Ehara K, Saka S. A comparative study on chemical conversion of cellulose between the batch-type and flow-type systems in supercritical water. Cellulose, 2002, 9: 301–311

Sasaki M, Fang Z, Fukushima Y, Adschiri T, Arai K. Dissolution and hydrolysis of cellulose in subcritical and supercritical water. Ind Eng Chem Res, 2000, 39: 2883–2890

Sakaki T, Shibata M, Miki T, Hirousue H, Hayashi N. Decomposition of cellulose in near-critical water and fermentability of the products. Energ Fuel, 1996, 10: 684–688

Sakaki T, Shibata M, Miki T, Hirousue H, Hayashi N. Reaction model of cellulose decomposition in near-critical water and fermentation of products. Bioresour Technol, 1996, 58: 197–202

Saka S, Ueno T. Chemical conversion of various celluloses to glucose and its derivatives in supercritical water. Cellulose, 1999, 6: 177–191

Ishikawa Y, Saka S. Chemical conversion of cellulose as treated in supercritical methanol. Cellulose, 2001, 8: 189–195

Köll P, Borchers G, Metzger J O. Thermal degradation of chitin and cellulose. J Anal Appl Pyrolysis, 1991, 19: 119–129

Reichardt C. Solvents and Solvent Effects in Organic Chemistry. Weinheim: VCH, 1988

Parker A J. Protic-dipolar aprotic solvent effects on rates of biomolecular reactions. Chem Rev, 1969, 69(1): 1–32

Tondo D W, Jr Pliego J R. Modeling protic to dipolar aprotic solvent rate acceleration and leaving group effects in SN2 reaction. J Phys Chem A, 2005, 109: 507–511

Voronova M I, Lebedeva T N, Radugin M V, Surov O V, Prusov A N, Zakharov A G. Interactions of water-DMSO mixtures with cellulose. J Mol Liq, 2006, 126: 124–129

Kawamoto H, Hatanaka W, Saka S. Thermochemical conversion of cellulose in polar solvent (sulfolane) into levoglucosan and other low molecular-weight substances. J Anal Appl Pyrolysis, 2003, 70: 303–313

Yamada T, Ono H. Rapid liquefaction of lignocellulosic waste by using ethylene carbonate. Bioresour Technol, 1999, 70(1): 61–67

Hosoya T, Kawamoto H, Saka S. Oxime-trimethylsilylation method for analysis of wood pyrolysate. J Anal Appl Pyrolysis, 2006, 77: 121–126

Sekiguchi Y, Frye J S, Shafizadeh F. Structure and formation of cellulosic chars. J Appl Poly Sci, 1983, 28: 3513–3525

Julien S, Chornet E, Tiwari P K, Overend R P. Vacuum pyrolysis of cellulose: Fourier transform infrared characterization of solid residues, product distribution and correlations. J Anal Appl Pyrolysis, 1991, 19: 81–104

Schwanninger M, Rodrigues J C, Pereira H, Hinterstoisser B. Effects of short-time vibratory ball milling on the shape of FT-IR spectra of wood and cellulose. Vib Spectr, 2004, 36: 23–40

Kawamoto H, Saka S. Heterogeneity in cellulose pyrolysis indicated from the pyrolysis in sulfolane. J Anal Appl Pyrolysis, 2006, 76: 280–284

Mok W S, Antal M J. Formation of charcoal from biomass in a sealed reactor. Ind Eng Chem Res, 1992, 31: 1162–1166

Saka S, Ehara K, Minami E. Efficient utilization of woody biomass with supercritical fluid technologies. Mokuzai Gakkaishi (in Japanese), 2005, 51: 207–217

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Natural Science Foundation of China (Grant No. 90610035)

Rights and permissions

About this article

Cite this article

Bao, G., Shiro, S. & Wang, H. Cellulose decomposition behavior in hot-compressed aprotic solvents. Sci. China Ser. B-Chem. 51, 479–486 (2008). https://doi.org/10.1007/s11426-008-0052-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11426-008-0052-1