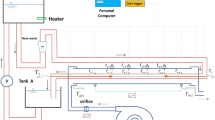

Basic parameters of a double-pipe enclosed heat exchanger were calculated for four possible cases of ideal heat-carrier flow structures. It was shown that the heat-transfer coefficient depended little on the ideal heat-carrier flow structures although the heat-transfer driving force and specific thermal power changed by a factor of three. Technological and geometrical parameters from a typical calculation of a double-pipe enclosed heat exchanger with plug flow of both heat carriers without and with temperature jumps at the heat-exchanger inlet were compared.

Similar content being viewed by others

References

O. Levenshpil, Process Chemical Engineering, Khimiya, Moscow (1969).

A. Yu. Zakgeim, Introduction to Modeling of Chemical Processes, Khimiya, Moscow (1982).

V. V. Kafarov, Cybernetics Methods in Chemistry and Chemical Engineering, Khimiya, Moscow (1985).

O. Yu. Elagina, V. M. Gusev, A. V. Shalimanova, and A. G. Buklakov, “Improving heat-emission efficiency in heat exchangers by use of capillary-porous coatings,” Khim. Neftegaz. Mashinostr., No. 9, 13–16 (2012).

V. P. Zakharov, K. S. Minsker, A. A. Berlin, and F. B. Shevlyakov, “Effect of the flow pattern on the convective heat transfer efficiency in tubular apparatuses,” Teor. Osn. Khim. Tekhnol., 38, No. 5, 528–531 (2004).

V. N. Bobylev, “Thermal design calculations for a heater taking into account the flow structure of the heat-transfer agent,” Khim. Prom. Segodnya, No. 7, 45–50 (2009).

A. B. Golovanchikov, N. A. Dul’kina, and Yu. V. Aristova, Modeling Hydromechanical and Heat- and Mass-Transfer Processes in Apparatuses and Reactors, VolgGTU, Volgograd (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, No. 4, pp. 12–15, April, 2017.

Rights and permissions

About this article

Cite this article

Golovanchikov, A.B., Vorontsova, S.B. Modeling of a Double-Pipe Enclosed Heat Exchanger with Temperature Jumps of Heat Carriers at the Heat-Exchanger Inlet. Chem Petrol Eng 53, 225–230 (2017). https://doi.org/10.1007/s10556-017-0325-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-017-0325-7