Abstract

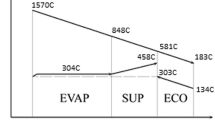

The objective of this article is to perform exergy analysis for thermal power plants based on the simulation software Aspen Plus. In this study, the main sections of the system including the boiler and the steam turbine are modeled using the Aspen Plus software. Exergy analysis of the modeled system is studied to obtain the energy loss distribution of the system. The influences of various operating conditions on the exergy efficiency of the system are investigated including combustion temperature, excess air coefficient, steam temperature, and steam pressure. The results show that exergy loss mainly occurs in the boiler and the steam turbine. The major sources of irreversibility are combustion and the internal thermal energy exchange in the boiler. The high-pressure turbine has the lowest exergy efficiency in the steam turbine; however, it assumes the largest work output, accounting for 37.08%. Therefore, reducing the irreversible loss in the boiler and improving the performance of the high-pressure turbine are the requirements for improving the system.

Similar content being viewed by others

References

Araújo AB, Brito RP, Vasconcelos LS (2007) Exergetic analysis of distillation processes—a case study. Energy 32:1185–1193

Chang H, Chuang S-C (2003) Process analysis using the concept of intrinsic and extrinsic extrinsic exergy losses. Energy 28:1203–1228

Chen L, Ma JJ, Zhao WD (2004) Applied program of thermodynamic calculation and exergy analysis of boilers in power plant. Appl Sci Technol 31(9):50–52

Delsman ER (2006) Exergy analysis of an integrated fuel processor and fuel cell (FP–FC) system. Energy 31:3300–3309

Eskin N, Gungor A, Özdemir K (2009) Thermodynamic analysis of a FBCC steam power plant. Energy Convers Manag 50:2428–2438

Kim JJ, Park MH, Kim C (2001) Performance improvement of integrated coal gasification combined cycle by a new approach in exergy analysis. Korean J Chem Eng 18(1):94–100

Kwak H-Y, Kim D-J, Jeon J-S (2003) Exergetic and thermoeconomic analyses of power plants. Energy 28:343–360

Li JY (1986) Exergy balance calculations for a power plant boiler. J Xi’An JiaoTong Univ 20:87–97

Li GZ, Furimsky E (2003) Aspen simulation of cogeneration plants. Energ Convers Manag 44:1845–1851

Mondal SS (2008) Modeling of transport processes and associated thermodynamic in irreversibilities ignition and combustion of a pulverized coal particle. Int J Therm Sci 47:1442–1453

Motahar S, Alemerajabi AA (2009) Exergy based performance analysis of a solid oxide fuel cell and steam injected gas turbine hybrid power system. Int J Hydrogen Energ 34:2396–2407

Prins MJ, Ptasinski KJ, Janssen FJJG (2007) From coal to biomass gasification: comparison of thermodynamic efficiency. Energy 32:1248–1259

Som SK, Datta A (2008) Thermodynamic irreversibilities and exergy balance in combustion processes. Prog Energy Combust Sci 24:351–376

Song XM, Xu HB et al (2009) Simulation of the NOx emissions during biomass combustion based on Aspen Plus. Acta Scientiae Circumstantiae 29:1696–1700

Sues A, Juraščík M et al (2010) Exergetic evaluation of 5 biowastes-to-biofuels routes via gasification. Energy 35:996–1007

Torío H, Schmidt D (2010) Development of system concepts for improving the performance of a waste heat district heating network with exergy analysis. Energy Build 42:1601–1609

Vidal A, Best R, Rivero R, Cervantes J (2006) Analysis of a combined power and refrigeration cycle by the exergy method. Energy 31:3401–3414

Wang Y, Dai ZH et al (2004) Simulation of entrained-flow bed coal gasifier by the method of Gibbs free energy minimization. Coal Convers 27(4):29–33

Zhang XP, Strmman AH et al (2008a) Model centered approach to early planning and design of an ecoindustrial park around an oil refinery. Environ Sci Technol 42(13):4958–4963

Zhang ZF, Tang LY et al (2008b) Pulverized coal gasification simulation based on Aspen Plus Software. Chem Fertil Des 46:14–18

Zhou L, Hu SY et al (2008) Study on co-feed and co-production system based on coal and natural gas for producing DME and electricity. Chem Eng J 136:31–40

Acknowledgments

This study was supported by the Science and Technology Program Subject of Liaoning Province, China (2009308001), the Science and Technology Subject Program of Education Department of Liaoning Province, China (LS 2010048), and the National Key Scientific and Technology Project for Water Pollution Treatment of China (2009ZX07208-002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hou, D., Shao, S., Zhang, Y. et al. Exergy analysis of a thermal power plant using a modeling approach. Clean Techn Environ Policy 14, 805–813 (2012). https://doi.org/10.1007/s10098-011-0447-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-011-0447-0