Abstract

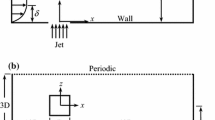

Two-phase CFD calculations, using a Lagrangian model and commercial code Fluent 6.2.16, were employed to calculate the gas and droplet flows and film cooling effectiveness with and without mist on a flat plate. Two different three dimensional geometries are generated and the effects of the geometrical shape, size of droplets, mist concentration in the coolant flow and temperature of mainstream flow for different blowing ratios are studied. A cylindrical and laterally diffused hole with a streamwise angle of 30° and spanwise angle of 0° are used. The diameter of film cooling (d) hole, and the hole length to diameter ratio (L/d) for both of geometries are 10 mm and 4, respectively. Also the blowing ratio ranges from 1.0 to 2.0, and the mainstream Reynolds number based on the mainstream velocity and hole diameter (Re d) is 6,219. The results are shown for different droplets diameters (1–10 μm), concentrations (1–5%) and mainstream temperatures (350–500 K). The centreline effectiveness and distribution of effectiveness on the surface of cooling wall are presented.

Similar content being viewed by others

Abbreviations

- A :

-

area (m)

- C :

-

concentration (kg m−3)

- C D :

-

drag coeffieint

- c p :

-

specific heat (J kg−1 K−1)

- D :

-

mass diffusion coefficient (m2 s−1)

- d :

-

diameter (m)

- F :

-

force (N)

- g :

-

gravity acceleration

- k :

-

turbulence kinetic energy (m2 s−2)

- k c :

-

mass transfer coefficient (m s−1)

- h :

-

convective heat transfer coefficient (W m−2 K−1)

- h fg :

-

latent heat (J kg−1)

- M :

-

blowing ratio (ρ c u c/ρ ∞ u ∞ )

- m :

-

mass (kg)

- Nu :

-

Nusselt number (hd/k)

- P :

-

pressure (N m−2)

- Pr :

-

Prandtl number (ν/α)

- R :

-

Reynolds stress tensor

- Re :

-

Reynolds number (ρul/μ)

- S :

-

source term

- Sc :

-

Schmidt number (ν/D)

- Sh :

-

Sherwood number (kcd/D)

- T :

-

temperature (K)

- t :

-

time (s)

- t p :

-

particle relaxation time

- α:

-

thermal diffusivity (m2 s−1)

- ε:

-

turbulence dissipation rate (m2 s−3)

- η:

-

adiabatic film cooling effectiveness ((Taw-T∞)/(Tc- T∞))

- λ:

-

heat conductivity (Wm−1 K−1)

- μ:

-

dynamic viscosity (kgm−1 s−1)

- ν:

-

kinematic viscosity (m2/s)

- ρ:

-

density (kg m−3)

- τ:

-

stress tensor (kg m−1 s−2)

- aw:

-

adiabatic wall

- c:

-

coolant or jet flow

- op:

-

operating condition

- p:

-

particle or droplet

- t:

-

turbulent

- sat:

-

saturate

- ∞:

-

values far away from droplets

References

Bunker R (2005) A review of shaped hole turbine film-cooling technology. J Heat Transf 127:441–453

Yuen CHN, Martinez-Botas RF (2003) Film cooling characteristics of a single round hole at various streamwise angles in a crossflow: part I. Effectiveness. Int J Heat Mass Transf 46:221–235

Goldstein RJ, Jin P, Olson RL (1998) Film cooling effectiveness and mass/heat transfer downstream of one row of discrete holes. ASME J Turbomach 121:225–232

Dittmar J, Schulz A, Wittig S (2003) Assessment of various film-cooling configurations including shaped and compound angle holes based on large-scale experiments. ASME J Turbomach 125:57–65

Bell CM, Hamakawa H, Ligrani PM (2000) Film cooling from shaped holes. ASME J Heat Transf 122:224–232

Baldauf S, Schulz A, Wittig S (1999) High resolution measurements of local heat transfer coefficients by discrete hole film cooling. ASME paper no. 99-GT-43

Walters DK, Leylek JH (1997) A systematic computational methodology applied to a three-dimensional film-cooling flow field. ASME J Turbomach 119:777–785

Walters DK, Leylek JH (2000) A detailed analysis of film cooling physics: part I-streamwise injection with cylindrical holes. ASME J Turbomach 122:102–112

Yuen CHN, Martinez-Botas RF (2005) Film cooling characteristics of rows of round holes at various streamwise angles in a crossflow: Part I. Effectiveness. Int J Heat Mass Transf 48:4995–5016

Kanani H, Shams M, Ebrahimi R, Ahmadian T (2008) Numerical simulation of film cooling effectiveness on a flat plate. Int J Numer Meth Fluids 56:1329–1336

Yu Y, Yen CH, Shih T, Chyu MK, Gogineni S (1999) Film cooling effectiveness and heat transfer coefficient distribution around diffusion shaped holes. ASME paper 99-GT-34

Thole K, Gritsch M, Schulz A, Wittig S (1998) Flow field measurements for film-cooling holes with expanded exits. ASME J Turbomach 120:327–336

Hyams D, McGovern K, Leylek J (1996) Effects of geometry on slot-Jet film cooling performance. ASME paper no. 96-GT-187

Guo T, Wang T, Gaddis JL (2000) Mist/steam cooling in a 180-degree tube bend surface. J Heat Transf 122:749–756

Guo T, Wang T, Gaddis JL (2000) Mist/steam cooling in a heated horizontal tube: part 2—results and modelling. ASME J Turbomach 122:366–374

Li X, Gaddis JL, Wang T (2003) Mist/steam heat transfer with jet impingement onto a concave surface. J Heat Transf 125:438–446

Li X, Wang T (2006) Simulation of film cooling enhancement with mist injection. J Heat Transf 128:509–519

Incropera FP, De Witt DP (1990) Fundamentals of heat and mass transfer, 3rd edn. Wiley, Singapore

EES, Engineering Equation Solver, F-Chart Software, written by Klein SA, Alvarado FL

Gibson MM, Launder BE (1978) Ground effects on pressure fluctuations in the atmospheric boundary layer. J Fluid Mech 86:491–511

Launder BE (1989) Second-moment closure: present and future? Int J Heat Fluid Flow 10(4):282–300

Launder BE, Reece GJ, Rodi W (1975) Progress in the development of a Reynolds-stress turbulence closure. J Fluid Mech 68(3):537–566

Hinds WC (1982) Aerosol technology, properties behaviour, and measurement of airborne particles. Wiley, New York

Turns SR (2000) An introduction to combustion: concepts and applications, 2nd edn. McGraw-Hill, Boston

Buck AL (1981) New Equations for computing vapor pressure and enhancement factor. J Appl Meteorol 20(12):1527–1532

Ranz WE, Marshall WR (1952) Evaporation from drops, part I. Chem Eng Prog 48(3):141–146

Kuo KKY (1986) Principles of Combustion. Wiley, New York

Ranz WE, Marshall WR (1952) Evaporation from drops, part II. Chem Eng Prog 48(4):173–180

Daly BJ, Harlow FH (1970) Transport equations in turbulence. J Phys Fluids 13:2634–2649

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kanani, H., Shams, M. & Ebrahimi, R. Numerical modelling of film cooling with and without mist injection. Heat Mass Transfer 45, 727–741 (2009). https://doi.org/10.1007/s00231-008-0465-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-008-0465-6