Abstract

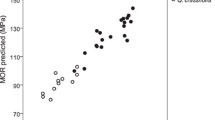

The effects of temperature and moisture content on selected mechanical properties associated with the chipping process were evaluated. In chipping, mechanical properties such as shear parallel to the grain, cleavage, and bending are involved. Matched samples of heartwood and sapwood were obtained from freshly harvested logs of black spruce and balsam fir to determine the variation of the studied mechanical properties between −30 and 20 °C, at intervals of 10 °C. Moisture content (MC), basic density (BD), and annual ring width (RW) were measured for each sample. For both wood species, temperature had a significant effect on all mechanical properties under freezing conditions (below 0 °C). This effect was more important for sapwood than for heartwood, which was explained by the difference in MC between these two types of wood. Between 0 and 20 °C, temperature and type of wood did not show any significant effect on the mechanical properties. Multiple regression models were obtained to predict the mechanical properties. These regressions showed that MC was the most important factor to explain the mechanical properties below 0 °C. However, for temperatures of 0 °C and higher, BD was the principal factor to predict the mechanical properties. RW was not a significant factor to predict any mechanical property. Cleavage was the most sensitive one to changes in temperature followed by shear, modulus of rupture, and modulus of elasticity. These results could be of great importance in the chipping process.

Similar content being viewed by others

References

American Society for Testing and Materials (ASTM) (1997) ASTM D 143-94 Standard methods of testing small, clear specimens of timber. Philadelphia, PA

Bodig J, Jayne B (1982) Mechanics of wood and wood composites. Van Nostrand Reinhold, New York

Christie RD (1986) Chip thickness and its effect on pulping needs further study. Pulp Pap Can 87(3):37–38, 41, 43

Christie RD (1987) Chip screening for pulping uniformity. Tappi J 70(4):113–117

Comact (2014) http://www.comact.com/. Accessed 22 July 2014

Deomano EC, Zink-Sharp A (2004) Bending properties of wood flakes of three southern species. Wood Fiber Sci 36(4):493–499

Forest Products Laboratory (FPL) (1999) Wood handbook - wood as an engineering material. General technical report FPL–GTR–113. Department of Agriculture, Forest Service, Forest Products Laboratory, Madison

Fuller, WS (1983) Chipping, screening and cleaning. Pulp and paper manufacture, vol 1. Properties of fibrous raw materials their preparation for pulping. M.J Kockrek and C.F.B. Sterens, Tappi. ISBN:0‐919893‐07‐4

Gerhards CC (1982) Effect of the moisture content and temperature on the mechanical properties of wood: an analysis of immediate effects. Wood Fiber 14(1):4–36

Green DW, Evans JW (2008) The immediate effect of temperature on the modulus of elasticity of green and dry lumber. Wood Fiber Sci 40(3):374–383

Green DW, Evans JW, Logan JD, Nelson WJ (1999) Adjusting modulus of elasticity of lumber for changes in temperature. For Prod J 49(10):82–94

Hatton JV (1975) WFPL chip quality analytical procedure: effect of chipper, wood species and season on production of pin chips and fines. Pulp Pap Can 76(8):64–70

Hellström LM, Gradin PA, Carlberg T (2008) A method for experimental investigation of the wood chipping process. Nord Pulp Pap Res J 23(3):339–342

Hellström LM, Isaksson P, Gradin PA, Eriksson K (2009) An analytical and numerical study of some aspects of the wood chipping process. Nordic Pulp Pap Res J 24(2):225–230

Hernández RE, Almeida G (2003) Effects of wood density and interlocked grain on the shear strength of three Amazonian tropical hardwoods. Wood Fiber Sci 35(2):154–166

Hernández RE, Boulanger J (1997) Effect of the rotation speed on the size distribution of black spruce pulp chips produced by a chipper-canter. For Prod J 47(4):43–49

Hernández RE, Lessard J (1997) Effect of cutting width and cutting height on the size distribution of black spruce pulp chips produced by a chipper-canter. For Prod J 47(3):89–95

Hernández RE, Quirion B (1993) Effect of chipper-canter knife clamp on the quality of chips produced from black spruce. For Prod J 43(9):8–14

Hernández RE, Quirion B (1995) Effect of knife clamp, log diameter, and species on the size distribution of pulp chips produced by a chipper-canter. For Prod J 45(7/8):83–90

Hoekstra PL, Veal MA, Lee PF, Sinkey JD (1983) The effects of chip size on mechanical pulp properties and energy consumption. Tappi J 69(9):119–122

Jessome AP (1977) Résistance et propriétés connexes des bois indigènes au Canada (Strength and related properties of woods grown in Canada) (Publication SP-514F). Forintek Canada Corp, Sainte-Foy

Koran Z (1979) Tensile properties of spruce under different conditions. Wood Fiber 11(1):38–49

Koubaa A, Zhang SY, Isabel N, Beaulieu J, Bousquet J (2000) Phenotypic correlations between juvenile-mature wood density and growth in black spruce. Wood Fiber Sci 32(1):61–67

Koubaa A, Zhang SY, Isabel N, Beaulieu J, Bousquet J (2005) Transition from juvenile to mature wood in black spruce (Picea mariana (Mill) B.S.P.). Wood Fiber Sci 37(3):445–455

Laganière B, Bédard N (2009) Debarking enhancement of frozen logs. Part I: effect of temperature on bark/wood bond strength of balsam fir and black spruce logs. For Prod J 59(6):19–24

Lunstrum SJ (1985) Balanced saw performance. U.S. Department of Agriculture, Forest Service, Forest Products Utilization, Technical Report No. 12

McLauchlan TA, Lapointe JA (1979) Production of chips by disc chippers. Joint Textbook Committee of the Paper Industry (TAPPI), Chip quality monograph, pp 15–32

Michel B (1978) Ice mechanics. Les Presses de l’Université Laval, Quebec City

Mishiro A (1990) Effect of freezing treatments on the bending properties of wood. Bull Tokyo Univ 82:77–189

Mishiro A, Asano I (1984) Mechanical properties of wood at low temperatures. Effect of moisture content and temperature on the bending properties of wood. II. Moisture content beyond the fiber-saturation point. Mokuzai Gakkaishi 30(4):277–286

Olson D, Hatton JV, Hunt K (1980) Effect of chip thickness in kraft-anthraquinone pulping of trembling aspen. Tappi J 63(2):109–110

Onwona-Agyeman S, Morioka N, Kondo M, Kitagawa K (1995) Seasonal changes in the modulus of elasticity of living branches of three coniferous species. Ecol Res 10(2):199–206

Panshin AJ, de Zeeuw C (1980) Textbook of wood technology. Michigan State University, New York

Parent B (2013) Quebec’s forest resources and industry. A statistical report, 2013 Edition Ministère des Ressources naturelles, Gouvernement du Québec, Québec

Robertsén L, Lönnberg B (1986) Significance of chip thickness in CRMP and RMP Part 2 A laboratory study with pine chips. Pap Puu 68(12):932–940

SAS Institute (2007) SAS/Stat User’s Guide, release 9.2 edn. SAS Institute Inc, Cary

Sawquip Sawmill Equipment (2014) http://www.sawquip.com/en/. Accessed 22 July 2014

Siimes FE (1967) The effect of specific gravity, moisture content, temperature and heating time on the tension and compression strength and elastic properties perpendicular to the grain of Finnish pine, spruce and birch wood and the significance of those factors on the checking of timber at kiln drying. Publication 84, The State Institute for Technical Research, Helsinki

Tikka P, Tähkänen H, Kovasin K (1993) Chip thickness vs. kraft pulping performance: experiments by multiple hanging baskets in batch digesters. Tappi J 76(3):131–136

Uhmeier A (1995) Some fundamental aspects of wood chipping. Tappi J 78(10):79–86

Wangaard FF (1950) The mechanical properties of wood. Wiley, New York

Zhang SY (1995) Effect of growth rate on wood specific gravity and selected mechanical properties in individual species from distinct wood categories. Wood Sci Technol 32(3):197–204

Acknowledgments

This research was supported by the Fonds Quebecois de la Recherche sur la Nature et les Technologies (FQRNT) and by FPInnovations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hernández, R.E., Passarini, L. & Koubaa, A. Effects of temperature and moisture content on selected wood mechanical properties involved in the chipping process. Wood Sci Technol 48, 1281–1301 (2014). https://doi.org/10.1007/s00226-014-0673-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-014-0673-9