Abstract

The unique properties of rare earth elements (REE) have made them crucial to a number of emerging and growing technologies [medical diagnosis equipment, critical military-based technologies, catalysts, computers, magnets, hybrid cars, windmills etc.] increasing their demand, and strategic importance. Recently, increased demand has led to supply problems, with corresponding price fluctuations and difficulties in obtaining REE for use in the cast iron industry.

The anti-nodularising action of deleterious residual elements up to a level corresponding to K = 2.0 (Thielman factor) can be counteracted by REE additions. In relatively high purity base iron in terms of anti-nodularising trace elements (K = 0.7 to 0.8) and 0.04 to 0.05% Mgres, higher REEres contents increased carbide tendency, for both un-inoculated and inoculated irons. A low content of REEres (0.005 to 0.01%) for K < 0.8 is practical and sufficient in a Ca-bearing FeSi alloy inoculated iron. The REE addition from a Ca,REE-FeSi alloy appears to be unnecessary, or even unacceptable, due to the risk of increased chill tendency.

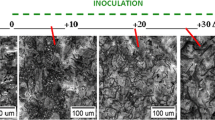

The use of a proprietary oxy-sulphide inoculant enhancer, (CaSi-based blend with S, O, Al, Mg) led to a substantial increase in the potency of the Ca-bearing inoculants. It was effective, when utilized in an in-mould inoculation of Mg-FeSi (0% REE or 0.26% REE) treatment, for K = 0.4–0.8. Avoidance of chill (free carbides), control of casting hardness and improved graphite quality parameters were observed with the proprietary oxy-sulphide inoculant.

Similar content being viewed by others

References

Rare Earth Elements. http://www.resources.nsw.gov.au/_data/assets/pdf_file/0016/238201/RareEarth.pdf

Rare earth element, www.wikipedia.org.

Hurst, C., “China’s Ace in the Hole: Rare Earth Elements,” Joint Forces Quarterly, Issue 59, 4th Quarter, pp. 121–126 (2010). http://www.ndu.edu/press/lib/images/jfq-59/JFQ59_121-126_Hurst.pdf.

Rare Earth Elements: Key for Future Technologies, http://rareearthinvestingnews.com/.

What are the Rare Earths?, www.ameslab.gov.

Bailey Grasso, V., “Rare Earth Elements in National Defense: Background, Oversight Issues, and Options for Congress”, Congressional Research Service, 7-5700, www.crs.gov, R41744.

Haxel, G.B., Hedrick, J.B. and Orris, G.J., “Rare Earth Elements—Critical Resources for High Technology U.S. Geological Survey”, http://geopubs.wr.usgs.gov/fact-sheet/fs087-02/

REE — Rare Earth Elements and their Uses, www.geology.com.

The Geology of Rare Earth Elements, Republished from: The Principal Rare Earth Elements Deposits of the United States, USGS Scientific Investigations Report 2010-5220, By Long, K.R., Van Gosen, B.S., Nora K. Foley, N.K. and Aniel Cordier, D., www.geology.com.

McLendon, R., “What are rare earth metals?, http://www.mnn.com/earth-matters/translating-uncle-sam/stories/what-are-rare-earth-metals#comments

China caps emissions for rare earth miners, http://www.mnn.com/earth-matters/wilderness-resources/stories/china-caps-emissions-for-rare-earth-miners

MISCHMETAL, http://metals.about.com/od/properties/a/What-Is-Mischmetal.htm

Generalic, E., http://www.periodni.com/rare_earth_elements.html

Lanthanide, www.wikipedia.org

http://www.resources.nsw.gov.au/_data/assets/pdf_file/0016/238201/RareEarth.pdf

http://www.ggg.gl/rare-earth-elements/rare-earth-elements-applications/

Rare Earth Metals.mht

Wilburn, D.R., “Wind Energy in the United States and Materials Required for the Land-Based Wind Turbine Industry From 2010 Through 2030”, Scientific Investigations Report 2011-5036, http://pubs.usgs.gov/sir/2011/5036/sir2011-036.pdf]

Beauford, R., “Rare Earth Elements Educational Resources Home Page”, www.rareearthelements.us.

Wojes, R., “Rare Earth Metals-Critical to High-Tech Devices”, www.metals.about.com.

D.I. Techniques. Suggestions for Ductile Iron Production, Published by Rio Tinto Iron & Titanium Inc. Canada (2002).

Margerie, J.C., “The Notion of Heredity in Cast Iron Metallurgy”, The Metallurgy of Cast Iron, Georgi Publishing Co, St. Saphorin, pp. 545–558 (1975).

Cast Iron Inoculation (the technology of graphite shape control) Booklet, ELKEM Foundry Products, www.foundry.elkem.com (March 2007).

Skaland, T., “New Approach to Ductile Iron Inoculation,” AFS Transactions, vol. 109, pp. 1073–1084, (2001).

Skaland, T., “A New Method for Chill and Shrinkage Control in Ladle Treated Ductile Iron”, Proc. of 2003 Keith Millis Symposium on Ductile Cast Iron, Oct. 2003, Hilton Head Island, USA, pp. 61–69; 66th World Foundry Congress, Sept. 2004, Istanbul, Turkey, pp. 975–987, World Foundry Organization.

White, D. and Riposan, I., “Studies of Nuclei on Ductile Iron-Why this is important for foundrymen”, AFS Conference, Saltillo, Mexico, September 2008.

Fras, E. and Lopez, H., “Eutectic Cells and Nodule Count-an Index of Molten Iron Quality,” International Journal of Metalcasting, vol 4, no. 3, pp. 35–61 (2010).

Naro, R.L., Williams, D.C., King, M. and Basaj, L., Improved, High-performance, Rare Earth-Free Inoculants,” Foundry Management & Technology, January 23 (2012).

Naro, R.L., Private Communication, 2012.

Thielman, T., “Zur Wirkung van Spurenelementen in Gusseisen mit Kugelgraphit”, Giessereitechnik, No.1, pp.16-24 (1970).

Riposan, I., Chisamera, M., Stan, S. and Adam, N., Influencing Factors on the High Purity Pig Iron/Steel Scrap Optimum Ratio in Ductile Iron Production”, Ductile Iron Society 2004 Annual Meeting, Montreal, Canada, June 23–25, 2004. Ductile Iron News Journal, Issue 2 (2004) http://www.ductile.org/magazine/2004_2/factors-influencing.htm

Riposan, I., Chisamera, M., Stan, S., Constantin, V., Adam, N. and Barstow, M., “Beneficial Remnant Effect of High Purity Pig Iron in Industrial Production of Ductile Iron,” AFS Transactions, vol. 114, pp. 657–666 (2006).

Riposan, I., Chisamera, M., Stan, S., “Performance of heavy ductile iron castings for windmills,” China Foundry, vol. 7, no. 2, pp. 163–170 (2010).

Riposan, I., Chisamera, M. and Stan, S., “Factors influencing on the microstructure and mechanical properties of as-cast and heat treated 400-18 grade ductile cast iron,” Int. Journal of Cast Metals Research, vol. 20, no. 2, pp. 64–67 (2007).

Riposan, I., Chisamera, M., Stan, S., Katz, S. and Ignat, S., “Critical Properties of CaC2 — bearing Reagents for Desulfurization of Liquid Iron,” AFS Transactions, vol. 110, pp. 1191–1200 (2002).

Chisamera, M., Riposan, I., Stan, S., Albu, C.B., Brezeanu, C. and Naro, R.L., “Comparison of Oxy-Sulfide Alloy Tablets and Ca-bearing FeSi75 for Late Inoculation of Low Sulfur Grey Irons,” AFS Transactions, vol. 115, pp. 481–493 (2007).

Ojo, S.S. and Riposan, I., “Alloy selection for in the mould inoculation to control chill width in ductile iron,” Materials Science and Technology, vol. 28, no. 5, pp. 576–581 (2010).

Uta, V. and Riposan, I., “Carbide Sensitivity of Rare Earth Inoculated Ductile Irons in Thin Wall Castings,” Metalurgia International, vol. XVIII, Special Issue No. 5, pp. 167–173 (2013).

Naro, R.L., U.S. Patent No. 6,281,988B1.

Naro, R.L., U.S. Patent No. 6,293,988B1.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Riposan, I., Chisamera, M., Uta, V. et al. The Importance of Rare Earth Contribution from Nodulizing Alloys and their Subsequent Effect on the Inoculation of Ductile Iron. Inter Metalcast 8, 65–80 (2014). https://doi.org/10.1007/BF03355583

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03355583