Abstract

In recent years, urbanization has grown rapidly in China. In 2021, China had an urban population of 914 million and a rural population of 498 million, with the urbanization rate rising from 37.7% in 2001 to 64.7%

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

1.1 Basic Situation of China’s Building Sector

1.1.1 Urban and Rural Demographic

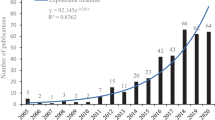

In recent years, urbanization has grown rapidly in China. In 2021, China had an urban population of 914 million and a rural population of 498 million, with the urbanization rate rising from 37.7% in 2001 to 64.7%, as shown in Fig. 1.1.

Urbanization is fundamentally characterized by the massive migration of people from rural areas to cities. In China, urbanization means that the people, for the most part, migrate to superlarge cities and county-level cities. According to relevant research by Xiaojiang Li,Footnote 1 former director of the China Academy of Urban Planning and Design, from 2000 to 2010, 41% of urban population growth was contributed by megacities, superlarge cities, and large cities, and 37% came from counties and towns. Recent years have seen a significant decline in the population growth of overpopulated large cities with excessively strict entry restrictions. For instance, the number of permanent residents in Beijing and Shanghai has remained basically stable since 2016.

On the other hand, rural residents migrate to counties and small towns, which is another characteristic of urbanization in China. Currently, about one-fourth of Chinese people now lives in small towns. Until 2021, China had a total of 1,482 counties, with a total population of 139 million in built-up areas, and 19,072 designated towns, with a total population of 166 million in built-up areas. Since 2001, the residential building stock in designated towns has doubled, from 2.86 to 6.32 billion square meters.Footnote 2 Historically, the main function of such small towns with a population of 10–100 thousand has been to provide surrounding rural areas with economic and trade, cultural, and medical services, and the support of their economic operation has been determined by the scale of surrounding agriculture, animal husbandry, and forestry they serve. The economic activities of these small towns have been dominated by the service sector, and it has been very difficult to arrange activities of the secondary industry there. As the proportion of urbanization rises and the agricultural population declines, the corresponding service functions of small towns also decrease accordingly. Housing vacancy occurs in these small towns when the ratio of their population to the surrounding rural population they serve is higher than a certain limit. How to plan the functions of these small towns and develop their infrastructure system represented by energy system scientifically and rationally to enable their sustainable development will be an important issue to be addressed in the new era.

1.1.2 Building Stock

Rapid urbanization drives continuous development of the construction sector, and the scale of China’s construction sector has been expanding. From 2007 to 2021, thanks to the rapid growth of building construction in China, the floor space greatly expanded in urban and rural areas. Specifically, from 2007 to 2014, the newly built building stock for civil buildings grew steadily from 2 billion m2 per annum to more than 4 billion m2. From 2014 to 2019, the newly built building stock of civil buildings in China slowly decreased year by year, but basically remained above 4 billion m2. In 2020, due to the impact of COVID-19, construction slowed down, and the newly built building stock of civil buildings dropped to 3.8 billion m2. In 2021, the pandemic in China was getting better, and the newly built building stock of civil buildings rose again to 4.1 billion m2. The total newly built building stock of urban residential buildings and public and commercial (P&C) buildings fell from about 3.6 billion m2 in 2014 to 3.34 billion m2 in 2020 and then rose again to 3.49 billion m2 in 2021 (Fig. 1.2). Driven by the large number of construction projects, the demolished building stock of urban residential areas and P&C buildings increased rapidly from 700 million m2 in 2007 to a stable level of approximately 1.6 billion m2 per year at present.

In 2021, residential buildings and non-residential buildings made up about 78 and 22% of the newly built building stock of civil buildings in China respectively. According to the difference in building functions, public and commercial (P&C) buildings can be categorized into offices, hotels, malls, hospitals, schools, and others. From 2001 to 2021, the main types completed each year were dominated by offices, malls, and schools. In 2021, the total newly built building stock of these three types accounted for about 70% of that of public and commercial (P&C) buildings, with the proportions of malls, office buildings, and schools at 29, 21, and 20% respectively. For the remaining types, hospitals and hotels had a smaller proportion of 7 and 3% respectively (Fig. 1.3).

Among the newly built building stock of civil buildings in 2021, the construction speed of urban residential buildings and P&C buildings was significantly higher than that in 2020. Among P&C buildings, the construction speed of schools and hospitals increased substantially compared to that in the previous year. The newly built building stock of school buildings increased by 13% and that of hospital buildings increased by 22% compared to those in the previous year.

Large-scale building construction activity has led to the rapid growth of China’s building stock every year. In 2021, the total building stock in China was about 67.8 billion m2, including urban residential buildings accounted for 30.5 billion m2, rural residential buildings accounted for 22.6 billion m2, and P&C buildings accounted for 14.7 billion m2 (Fig. 1.4). The floor area for northern urban heating stood at 16.2 billion m2.

Source Estimation results from CBEEM of the Building Energy Research Center (BERC), Tsinghua University. The newly built building stock entered in the model is the data under the statistical standards for construction enterprises as specified in the China Statistical Yearbook on Construction

China’s existing building stock (2001–2021).

1.2 Demarcation of China’s Energy Consumption and GHG Emissions in the Building Sector

1.2.1 Calculation Method of Energy Consumption in the Building Sector

Energy consumption for the building sector covers different phases of buildings life cycle. In this report, the embodied energy consumption of buildings and the building operation energy consumption are analyzed respectively. The embodied energy consumption of buildings refers to the energy consumption of building material exploration, production, transportation and on-site construction and also includes the energy consumption during building demolition. In China’s statistical standards, civil building construction, production building (non-civil building) construction, and infrastructure construction are included in the construction sector, so their energy consumption is collectively known as the embodied energy consumption related to the construction sector. Based on the China Building Energy and Emission Model of BERC, Tsinghua University, this book provides the analysis data of the standard for embodied energy consumption of China’s construction sector and the standard for embodied energy consumption of China’s civil buildings (see Sect. 1.3.2 for details).

Building operation energy consumption, which is the focus of this book, refers to the energy consumption from the operation of civil buildings, including the energy consumed by the provision of heating, ventilation, air conditioning, lighting, cooking, and domestic hot water (DHW) to occupants or users in residential buildings, office buildings, schools, malls, hotels, transportation hubs, recreational and sports facilities, and other non-industrial buildings, and energy consumed by service functions of such buildings. It is very difficult to distinguish the operational energy consumption of buildings that fully serve industrial production processes from the industrial production energy consumption, because the energy consumption in ventilation, air conditioning, and purification of factory buildings including metallurgical factory buildings and integrated circuit or pharmaceutical production factory buildings accounts for a very large proportion in the production energy consumption. However, it is very difficult to include such energy consumption in building energy consumption. Hence, this report does not discuss the buildings serving production processes and only studies civil buildings.

Based on our long-term research on the energy consumption of civil building operation in China and given the difference in heating methods in winter between northern and southern China, the difference in architectural forms and lifestyles between urban and rural areas, and the difference in personnel activities and energy use equipment between residential and P&C buildings, this report divides the building energy use in China into four categories, i.e. northern urban heating (NUH) energy use, urban residential building energy use (excluding NUH energy use), public and commercial building energy use (excluding NUH energy use), and rural residential building energy use, which are defined in detail as follows.

-

(1)

NUH energy use

This refers to the energy consumption of heating in winter, including all forms of centralized heating and decentralized heating, in provinces, autonomous regions, and municipalities that adopt centralized heating, including all urban areas of Beijing, Tianjin, Hebei, Shanxi, Inner Mongolia, Liaoning, Jilin, Heilongjiang, Shandong, Henan, Shaanxi, Gansu, Qinghai, Ningxia, and Xinjiang as well as part of Sichuan. Heating is also needed in winter in Tibet, western Sichuan, and part of Guizhou, but should be considered separately as the local energy situations, issues, and characteristics are completely different from those in northern China. The reason for the separate calculation of NUH energy use is that centralized heating has been the main heating method in northern urban areas, including a large number of city-level heating networks and community-level heating networks. Different from other categories of building energy use, in which the calculation is based on the consumption of a single building or a single household, NUH energy use is largely related to the structural form and operation mode of a heating system, and the actual value of energy use is counted and calculated in a unified manner based on the heating system, so NUH energy use is taken as a separate category and treated differently from other categories of building energy use. Based on the form and scale of heat source systems, the current heating systems can be classified into centralized heating systems, which adopt such methods as large- and medium-scale coal-fired combined heat and power (CHP), large- and medium-scale gas-fired CHP, small-scale coal-fired CHP, small-scale gas-fired CHP, large coal-fired boilers, large gas-fired boilers, district coal-fired boilers, district gas-fired boilers, heat pump for centralized heating, residual heat from nuclear power and industrial residual heat, and household heating systems, which adopt such methods as household gas furnaces, household coal furnaces, air conditioners and heat pumps for decentralized heating, and direct electric heating. The main types of energy sources used include coal, gas, and electricity. This report studies the primary energy consumption, including the primary energy or electricity consumption at heat sources and the electricity consumption of equipment (fans and water pumps) serving heating systems. Such energy consumption can also be divided into the conversion loss from heat sources and heating stations, the heat loss and energy consumption of the distribution pipe networks, and the final heat gains of buildings.

-

(2)

Urban residential building energy use (excluding NUH energy use)

This refers to the energy consumption of urban residential buildings, except for the heating energy consumption in northern China. In terms of energy end-users, it includes energy consumption of household appliances, air conditioners, lighting, cooking, and domestic hot water, as well as energy consumption of heating in winter in provinces, autonomous regions, and municipalities in the hot-summer and cold-winter (HSCW) zone. The main types of commercial energy sources used in urban residential buildings include electricity, coal, natural gas, liquefied petroleum gas (LPG), and city gas. Decentralized heating is mostly adopted in winter in the HSCW zone, and the energy consumption of the following heating methods all falls into this category: building space heating methods such as air source heat pumps and direct electric heating, and local heating methods such as fire pans, electric blankets, and electrical hand warmers.

-

(3)

Public and commercial building energy use (excluding NUH energy use)

The public and commercial (P&C) buildings here refer to buildings where people carry out various public activities including office buildings, commercial buildings, tourism buildings, scientific research, educational, cultural, and medical buildings, communication buildings, and transportation buildings in urban and rural areas. Except for NUH energy consumption, the energy consumption of activities in buildings includes the energy consumption of air conditioning, lighting, sockets, elevators, cooking, and service facilities, as well as the energy consumption of heating of urban P&C buildings in winter in the HSCW zone. The types of commercial energy sources used in P&C buildings include electricity, gas, fuel oil, and coal.

-

(4)

Rural residential building energy use

This refers to the energy consumption of rural households, including cooking, heating, cooling, lighting, hot water, household appliances, etc. The main types of energy sources used in rural residential buildings include electricity, coal, LPG, gas, and biomass energy (straw and firewood). The consumption of biomass energy is not included in the national macrostatistics of energy. However, as an important part of rural residential building energy use, it will be listed separately in this report.

In this report, actual consumption of electricity other types of energy is counted and calculated separately whenever possible. If they have to be combined, all energy sources will be converted into primary energy sources for addition, namely, the electricity consumption will be converted into primary energy consumption calculated in standard coal based on the annual average coal consumption for power supply in China. As to the CHP method of centralized heating source for building operation, the input fuels are allocated based on the exergy values of output electricity and heat according to relevant provisions of the Standard for Energy Consumption of Building (GB/T 51,161-2016). In this report, the conversion coefficient for the exergy of heat is calculated based on an ambient temperature of 0 °C and a supply/return water temperature of 110 °C/50 °C, and the conversion coefficient for heat is 0.22.

1.2.2 Calculation Method of Carbon Emissions in the Building Sector

The embodied carbon emissions of buildings include the carbon emissions from the building material production, transportation, on-site construction, and demolition of civil buildings. In China’s statistical standards, civil building construction, production building (non-civil building) construction, and infrastructure construction are included in the construction sector, so their carbon emissions are collectively known as the embodied carbon emissions related to the construction sector. Based on the China Building Energy and Emission Model of BERC, Tsinghua University, this report provides the analysis data of the standard for embodied carbon emissions of China’s construction sector and the standard for embodied carbon emissions of China’s civil buildings (see Sect. 1.4.2 for details).

Carbon emission during building operation mainly includes the carbon emission from the direct burning of fossil fuels and the indirect use of non-fossil energy during the operation of buildings, which consists of three main types:

-

1.

Direct carbon emission: It refers to the direct emission of carbon dioxide in buildings by burning fossil fuels including coal, fuel oil, and gas. The carbon emission can be calculated based on the types of fuels and their different carbon emission factors.

-

2.

Indirect carbon emission from electricity use: It refers to the carbon emission during the generation of electricity transmitted into buildings from the outside. The carbon emission can be calculated through the multiplication of the total external electricity used for buildings by the average carbon emission factor of electricity in the power grid, and the PV power generation and electricity consumption in buildings themselves are not counted.

-

3.

Indirect carbon emission from heating: It refers to the indirect carbon emission resulting from centralized heating in northern urban areas. The centralized heating systems in northern urban areas adopt combined heat and power generation or centralized coal- and gas-fired boilers for the supply of heat. In this regard, carbon dioxide emitted by coal- and gas-fired boilers fall into the indirect carbon emission from building heating, while carbon emissions of combined heat and power generation plants are allocated according to exergy values of output electricity and heat. In this report, the conversion coefficient for the exergy of heat is calculated based on an ambient temperature of 0 °C and a supply/return water temperature of 110 °C/50 °C, and the conversion coefficient for heat is 0.22. That is to say, 22% of the output heat is treated as the equivalent electricity, which shares the total carbon dioxide emitted from power plants with the output electricity.

In addition to carbon emissions, non-CO2 greenhouse gas (GHG) emissions can also occur during building operation, which mainly refers to the GHG effect caused by the leakage of refrigerants from refrigeration and heat pump equipment in buildings, and is measured in carbon dioxide equivalent. This type of emission is analyzed in detail in Sect. 1.4.3. In this report, the China Building Energy and Emission Model (CBEEM) built by BERC, Tsinghua University is used to calculate and analyze all types of emissions in China’s building sector (See Sect. 1.4 for details).

1.3 Energy Consumption of China’s Building Sector

1.3.1 Building Operation Energy Consumption

The building energy consumption data in this chapter comes from the results of research with the China Building Energy and Emission Model (CBEEM) built by BERC, Tsinghua University, and is used to analyze the development of building energy consumption and carbon emissions in China. In 2021, the total commercial energy consumption of building operation was 1.11 gigatonnes of coal equivalent (Gtce), accounting for about 21% of the total energy consumption in China, and the commercial energy consumption and biomass energy consumption of buildings amounted to 1.2 Gtce (biomass energy consumption: about 0.09 Gtce), with details given in Table 1.1.

From 2010 to 2021, the total energy consumption of buildings and electricity consumption increased dramatically, as shown in Fig. 1.5. The COVID-19 pandemic slowed down various social activities, and the growth in electricity consumption of buildings in 2020 was slower than that in 2019. However, as production and life returned to normal in 2021, the electricity consumption of buildings rose greatly. The electricity consumption of buildings in the whole society exceeded 2.2 PWh in 2020.

The scale, intensity, and total quantity of the four categories of building energy use are represented in the four blocks in Fig. 1.6 respectively, in which the horizontal axis represents building floor area, and the vertical axis represents energy use intensity per square meter of building. The total area of the four blocks represents the total energy consumption of buildings. In terms of building floor area, urban residential buildings and rural residential buildings have the largest floor area, while the floor areas of NUH and P&C buildings account for about one-fourth and only one-fifth of the total, respectively. However, from the perspective of energy use intensity, the energy use intensity of P&C buildings and NUH is higher than that of the other two categories. Therefore, in terms of total energy use, each of the four categories accounts for about one-fourth of the total building energy consumption. In recent years, the growth in the scale and average energy use intensity of P&C buildings have made their energy consumption the largest proportion of the building energy consumption in China.

Building operation energy consumption in China (2021). Note Electricity, heat, and fuels are uniformly converted into primary energy, which is measured in standard coal, and the electricity consumption is converted into primary energy consumption calculated in standard coal based on the annual average coal consumption for power supply in China. The conversion coefficient in 2021 was 302 gce/kWh

Figure 1.7 shows the changes in the total quantity and intensity of the four categories of energy use from 2010 to 2021. The total quantity and intensity in the four categories mainly exhibit the following characteristics:

-

The energy use intensity in NUH was relatively large but has been decreasing with the improvement of the new energy-saving standards and the heat source efficiency in recent years, and the total energy consumption remained stable without any further increase.

-

Energy use intensity per unit area of P&C buildings continued to increase. The increasing terminal energy demand of P&C buildings (air conditioners, devices, lighting, etc.) was the major cause for the increase in building energy use intensity. In particular, some large new buildings with large-scale centralized systems have been constructed in many cities in recent years, with energy use intensity much higher than that of similar buildings. As the size of P&C buildings grows, their total energy consumption is still increasing.

-

The energy use intensity per household of urban residential buildings increased because there was an increasing demand for domestic hot water, air conditioners, and household appliances. The issue of heating in winter in the HSCW zone also aroused extensive discussions. There was not too much increase in the energy consumption of lighting in residential buildings because of the adoption of energy-efficient illumination devices. The energy use intensity of cooking also remained unchanged. With the further promotion of urbanization and the growth in the size of urban residential buildings, their total energy consumption is still increasing.

-

The commercial energy use intensity per household of rural residential buildings increased slowly. As the rural population and the number of households slowly decreased, commercial energy consumption in rural areas remained stable. However, as household appliances became more popular in rural areas and the policy of “switching from coal to electricity” was implemented for clean heating in northern China, electricity consumption has increased dramatically in recent years. Meanwhile, biomass energy use has dropped continuously. Hence, the total energy use of rural residential buildings has declined slowly in recent years.

-

(1)

NUH

In 2021, the energy consumption of NUH was 212 million tce, making up 19% of the total energy consumption of buildings in China. From 2001 to 2021, the NUH area tripled from 5 to 16.2 billion m2, while the total energy consumption increased, but did not double. Obviously, the increase in total energy consumption was less than the increase in building floor area, indicating that remarkable results had been achieved in energy saving. The average energy consumption per unit area of heating was 13.1 kgce/m2 in 2021, a significant decline from 23 kgce/m2 in 2001. Specifically, the main reasons for the decrease in energy use intensity include the improvement of building insulation, which resulted in the decrease in the heat demand of buildings, as well as the increased share of efficient heat sources, and the improvement of operation management. In recent years, the total energy consumption of NUH has been on a declining trend from the peak around 2017. Due to the COVID-19 pandemic, the heating time was extended to varying degrees in different places in the 2019–2020 heating season. According to the statistical data released in the 2022 Annual Report on Urban Heating Development in China, 75% of cities extended the heating time in the 2019–2020 heating season, so the total energy consumption in NUH went up a little in the 2019–2020 heating season.

Gradual improvement of building envelope performance. In recent years, the Ministry of Housing and Urban–Rural Development of the People’s Republic of China has adopted various methods to improve building insulation, including the establishment of building energy efficiency design codes that cover different climate zones and building types, the special examination of energy-saving work that started from 2004, and the renovation of existing residential buildings during the 13th Five-Year Plan period. During the 13th Five-Year Plan period, the energy efficiency design standard for new urban residential buildings in severe cold and cold areas in China was raised to “75% energy-saving standard”, approximately 10 million square meters of ultra-low and near zero energy buildings completed construction, and 514 million square meters of existing residential buildings and 185 million square meters of P&C buildings completed the energy-saving retrofit. These methods have greatly enhanced building insulation in China and lowered the actual heating demand of buildings, especially in northern China.

Optimization of heat source structure and significant improvement of heat source efficiency. Recent years have seen a gradual increase in the share of efficient CHP to gradually replace boilers. The results of urban heating surveys in 2013, 2016, and 2020 (as shown in Fig. 1.8) revealed that the proportion of CHP in heat sources for NUH was 42, 48, and 55% respectively in the three years. Gas-fired boilers replaced coal-fired boilers. From 2013 to 2020, the proportion of coal-fired boilers dropped from 42 to 13%, while that of gas-fired boilers increased from 12 to 22%. In the meantime, all types of new heat sources kept on growing, with rising proportions of industrial residual heat, residual heat from nuclear power, ground-source heat pumps, and biomass in heating. Heating system efficiency has also been increasing notably in recent years, thus enabling the overall improvement of the efficiency of all types of centralized heating systems.

-

(2)

Urban Residential Buildings (Excluding NUH)

Urban residential building energy consumption (excluding NUH) in 2021 was 278 million tce, accounting for one-fourth of the total commercial energy consumption in the building sector. Electricity consumption was 605.1 TWh. With the economic and social development and the improvement of living standards in China, the average annual growth rate of urban residential building energy consumption reached up to 7% from 2001 to 2021, and the terminal electricity consumption in 2021 quintupled that in 2001.

From the view of energy use, cooking, household appliances, and lighting consumed the most energy in urban residential buildings (excluding NUH) in China. Thanks to policies and projects for improving the energy efficiency of cooking, household appliances, and lighting, the terminal energy consumption of these three categories was kept under control, and the total energy consumption has undergone a slower increase in recent years. Improving energy efficiency and lowering standby energy consumption should become the optimal methods to limit the energy consumption of cooking, household appliances, and lighting. For example, the promotion of energy-saving lamps significantly improved the lighting efficiency of residential buildings. Energy efficiency standards and behaviors need to be upgraded to lower the electricity consumption from long standby time and frequent reheating and restarting of household appliances. The production standards of such appliances as TV set-top boxes, water dispensers, and electric toilet seats need to be improved to lower the waste of energy when they are in standby mode. The methods, for example, include improving the controllability of set-top boxes, enhancing the insulation capacity of water dispensers, and adopting intelligent control of toilet seats. Policy incentives or subsidies shall not cover electric appliances such as clothes dryers, which may change the lifestyle, and we should watch for the energy spikes of these high energy consumption appliances. Even though the energy consumption of winter heating, summer cooling, and domestic hot water accounts for a smaller proportion in the HSCW zone and the energy consumption per household is at a low level, they have been growing rapidly. The annual average growth rate of heating energy consumption in the HSCW zone could be well over 50%. Therefore, saving terminal energy use for those three categories should be our priority in the next stage of energy saving for urban residential buildings. We should avoid the massive adoption of centralized systems, promote decentralized systems in residential buildings, improve the energy efficiency standards of distributed equipment, and prevent drastic energy consumption increases while improving the indoor service level. Refer to the China Building Energy Use and Carbon Emission Yearbook 2021 for detailed discussions about the energy-saving and emission-reduction pathways for urban residential buildings in China.

-

(3)

P&C Buildings (Excluding NUH)

In 2021, the total floor space of China’s P&C buildings was approximately 14.7 billion m2, and the total energy consumption of P&C buildings (excluding NUH) was 0.386 Gtce, making up 35% of that of the building sector. Electricity consumption stood at 1.17 PWh. The total area of P&C buildings and the proportion of large P&C buildings were all on the rise, which led to an increase in energy demand. The energy consumption per unit area of P&C buildings grew from 17 kgce/m2 in 2001 to over 26.3 kgce/m2 in 2021. The energy use intensity increased rapidly, and the total energy consumption surged as well.

In 2020, due to the impact of COVID-19, the operation duration and intensity of public and commercial buildings were subject to pandemic-related control measures, leading to a slight decrease in the average energy use intensity of public and commercial buildings in China. In 2021, the growth rate of energy used in the operation of public and commercial buildings picked up. Since 2001, the newly built building stock of P&C buildings amounted to almost 8 billion m2, approximately 79% of the current stock. This means that three-fourths of P&C buildings were built after 2001. There are two reasons for this increase. First, a lot of new commercial buildings such as office buildings and commercial complexes have been constructed in recent years. Second, the scale of public service buildings such as schools, hospitals, and sports stadiums has increased due to the necessity for the gradual perfection of relevant infrastructure to promote the building of a well-off society in an all-around way and the improvement of public services. In recent years, the proportion of school and hospital buildings in the new public and commercial buildings has been increasing gradually. In 2021, there were more new hospital and school buildings than new office and hotel buildings.

While the stock of P&C buildings is growing, the number of large-scale P&C buildings is also increasing. In particular, many public and commercial buildings completed in recent years are large top-grade commercial buildings with central air-conditioning. Their electricity consumption per unit area is over 100 kWh/m2, while the electricity consumption of smaller schools, offices, and stores built in the past is approximately 60 kWh/m2. The average electricity consumption of public and commercial buildings will continue to increase as the proportion of such new public and commercial buildings with high energy consumption in the total number of public and commercial buildings has been on the rise. Due to the volume and form constraints of such new buildings, the energy use intensity of air conditioning, ventilation, lighting, and elevators in them is much higher than that in general public and commercial buildings. This is also an important cause of the continuous growth in the energy use intensity of public and commercial buildings in China. Refer to the China Building Energy Use and Carbon Emission Yearbook 2022 for detailed discussions about paths toward energy saving and emission reduction for P&C buildings in China.

-

(4)

Rural Residential Buildings

In 2021, the commercial energy consumption of rural residential buildings was 0.232 Gtce, accounting for 21% of the total energy consumption of buildings in China. Electricity consumption was 375.4 TWh, and the consumption of rural biomass energy (straw and firewood) was equivalent to about 0.09 Gtce. From 2001 to 2021, urbanization led to a decline of the rural population from 800 to 500 million, and the scale of rural residential buildings was maintained at approximately 23 billion m2 and has begun to decrease slowly in recent years.

Owing to the higher availability of electricity in rural areas, higher income for rural residents, and more household appliances, the electricity consumption per household in rural areas has increased rapidly. For instance, the number of air conditioners per hundred households in rural areas increased from 16 in 2001 to 73.8 in 2020, which led to not only the growth of electricity consumption but also a longer peak power load in rural areas during summer. The implementation and promotion of “switching from coal to electricity” in northern China contributed to significant growth in winter heating electricity consumption and peak power load there. Moreover, increasing biomass energy has been replaced by commercial energy, leading to a rapid reduction of the proportion of biomass energy in household energy consumption in rural areas.

China released the Work Plan for Implementation of the PV Poverty Alleviation Project in 2014, which proposed the development of the photovoltaic (PV) industry in rural areas as an important means of poverty alleviation. A new energy system based on rooftop PV may be built by taking advantage of abundant renewable resources in rural areas. Such a system can realize the net power output to the power grid while meeting the energy demands of rural life, production, and transportation. It can totally cancel the use of fossil and biomass fuels while raising the living standard in rural areas. Thus, it will not only root out the environmental pollution and carbon emission problems caused by the burning of fossil and biomass fuels but also make the production and output of zero-carbon energy another important economic activity in rural areas. Besides, this can make an important contribution to the sustainable development of China’s energy system and become an important part of the rural revitalization strategy.

In recent years, with the thorough implementation of haze control measures and clean heating in eastern China, governments at all levels and relevant enterprises have made huge investments to increase the power supply capacity, lay gas pipe networks and change original small household coal-fired furnaces into low-pollution forms in rural areas, which leads to a substantial increase in electricity and gas consumption. The change in rural energy structure will lead to a fundamental transformation of rural energy use patterns, thus facilitating the modernization of rural areas. This opportunity should be leveraged and scientific planning should be made to revolutionize rural energy supply and consumption and establish a new energy system with renewable energy sources as the mainstay for rural residents, which will play an important role in the current energy revolution of China.

1.3.2 Embodied Energy Consumption of Building Sector

China’s continuous advancement of urbanization in the last two decades has also enabled the embodied energy consumption of civil buildings to become an important part of the total energy consumption of the whole society. A large quantity of building materials is needed, the production process of which lead to great energy consumption and carbon emissions. This is one of the key reasons for the continuing growth of energy consumption and carbon emissions in China.

According to the estimation from the BERC, embodied energy use of civil buildings in China amounted to 0.52 gigatonnes of coal equivalent (Gtce), accounting for 10% of China’s total energy consumption. The embodied energy use of civil buildings in China grew from 0.24 Gtce in 2004 to 0.52 Gtce in 2021, as shown in Fig. 1.9. Due to the slow decrease in the newly built building stock of civil buildings in recent years, its embodied energy use has also dropped gradually since 2016. The newly built building stock of civil buildings declined markedly in 2020 due to the impact of COVID-19 and rebounded in 2021 with the stabilization of the pandemic. As a result, the embodied energy of civil buildings fell considerably in 2020 from that in the previous year and rose again in 2021. In 2021, the embodied energy of urban residential, rural residential, and P&C buildings accounted for 71, 5, and 24%, respectively.

Source Estimation by BERC, Tsinghua University. This figure only covers civil building constructionFootnote

The newly built building stock data is based on the data under “the statistical standards for construction enterprises as specified in the China Statistical Yearbook on Construction”.

Embodied energy use of China’s civil buildings (2004–2021).

In fact, the construction sector consists of not only civil buildings but also buildings for production purposes and infrastructures such as motorways, railways, and dams. The embodied energy use of the construction sector mainly includes all types of energy use related to the construction of buildings and infrastructures. According to the calculation of BERC, Tsinghua University, the total embodied energy use of China’s construction sector in 2021 was 1.37 Gtce, accounting for up to 26% of the primary energy consumption of the whole society. From 2004 to 2021, embodied energy use in China’s construction sector grew from approximately 0.4–1.37 Gtce, as shown in Fig. 1.10. Embodied energy from building materials is the mainstay of the total embodied energy use of buildings, in which iron and steel and cement production consumes more than 80%.

Source Estimation by BERC, Tsinghua University. The construction sector involves the construction of civil buildings, production buildings, and infrastructuresFootnote

Data about the consumption of building materials is from the China Statistical Yearbook on Construction.

Embodied energy consumption of China’s construction sector (2004–2021).

The construction demands of rapid urbanization in China have not only driven the growth of energy consumption directly but also determined China’s industrial structure which is dominated by traditional heavy and chemical industries including steel and cement. This is also a key reason for the high energy consumption per unit of industrial value added in China.

There was 1.27 Gtce of industrial energy used for producing building materials in 2021. Between 2013 and 2021, building materials accounted for approximately 40% of the total industrial energy consumption, as shown in Fig. 1.11. The fast pace of urbanization in China drove the demand for building materials, which was the key reason why the higher percentage of total energy consumption was represented by iron and steel, building materials, and other traditional heavy industries.

As urbanization and infrastructure development have achieved initial progress in China, the transformation of the construction mode is ongoing. In 2020, the per capita floor area for urban residential buildings was 33 m2 in China, which was close to that of some developed countries in Asia, such as Japan and South Korea, but still far lower than that of the US. The reason was that during China’s urbanization, the main type of building in the urban communities was apartments instead of single houses, such as that of the US. From the perspective of urban form, the utilization ratio of P&C buildings was high in China because of the high-density large city mode of development, so it is unnecessary to follow the per capita P&C building scale in Europe and America. In the future, there will be no more rapid growth of iron and steel, building materials, and other high energy consumption industries, so long as there is less demolition, and the building life cycle can be properly maintained. Therefore, for the next round of urbanization, the demolition of buildings that have not reached the end of life shall be abolished. Technologies to extend the building life cycle shall be invented. Buildings and infrastructures should be properly repaired, and the building life cycle should be extended to facilitate industrial transformation and total energy control.

1.3.3 GHG Emissions of China’s Building Sector

1.3.3.1 Carbon Dioxide Emissions from Building Operation

The carbon dioxide emissions from building operation are affected by the growth in total energy demand of buildings, the improvement of building energy efficiency, and the adjustment of building fuel types and energy supply structure. Electricity, coal, and gas were the major energy sources for building operation. Electricity accounted for 70% of the total energy use in urban residential buildings and P&C buildings, in which CO2 was indirectly emitted. The adoption of CHP in NUH could also lead to indirect CO2 emissions. The percentage of coal and gas consumption was higher than that of electricity consumption for NUH and rural residential buildings. The percentage of coal and gas consumption was about 90% for NUH and the percentage of fossil energy consumption was about 50% for rural residential buildings, which led to massive direct carbon dioxide emissions. In another aspect, as the percentage of zero-carbon electricity has increased in China, the average emission factors have declined tremendously, at 558 gCO2/kWh in 2021. Besides, the share of electricity consumption in building operation energy consumption gradually increased as well. These two trends have promoted the low-carbon development of building operation energy consumption.

According to the analysis results from CBEEM, in 2021, the total carbon emissions during building operation in China were 2.2 billion tonnes of carbon dioxide (Gt CO2), equivalent to 1.6 t per capita carbon emissions and 32 kg/m2 of average carbon emissions per unit area. In the total carbon emissions, the proportions of direct carbon emissions (0.51 Gt CO2), indirect carbon emissions from electricity use (1.24 Gt CO2), and indirect carbon emissions from heating (0.43 Gt CO2) were 23, 57, and 20%, respectively, as shown in Fig. 1.12.

-

(1)

Direct Carbon Emission

In 2021, the direct carbon emissions of buildings were 510 million tons of CO2, including about 230 million tons of CO2 directly emitted from urban and rural cooking, about 150 million tons of CO2 emitted from household gas- and coal-fired heating boilers,Footnote 6 and 130 million tons of CO2 directly emitted from natural gas consumption for hot water, steam boilers, absorption refrigeration, and other purposes. Emissions from rural areas accounted for more than half of the direct carbon emissions.

In recent years, with the vigorous promotion of “switching from coal to electricity”, “switching from coal to gas” and clean heating in rural areas, the direct carbon emissions in the building sector of China have been declining slowly from the peak around 2015. Direct carbon emissions of the building sector will continue to decrease and no longer reach a new peak as long as electrification is continuously promoted in new buildings.

To reduce direct carbon emissions of the building sector to zero, the key lies in the point-in-time and intensity of promoting “electrification”. It is expected that direct carbon emissions of buildings will be reduced to zero during 2040–2045. Analyses indicate that electrification will not increase the operation cost in 80% of all cases and that the initial investment in equipment will be returned in about 5 years through the reduction of operating cost. Therefore, the major obstacle to promoting electrification in buildings is not economic cost but the change in the concept of energy use and cooking culture. Increasing the publicity of “zero carbon emissions of buildings by electrification” among the public and promoting “switching from gas to electricity” in new and existing buildings are the most important approaches to realizing zero direct carbon emissions from building operation.

-

(2)

Indirect Carbon Emission from Electricity Use

In 2021, the electricity consumption by building operation in China was 2.2 PWh, and the indirect carbon emission from electricity use was 1.24 billion tons of CO2. At present, the per capita electricity consumption of the building sector in China is one-sixth of that in the US and Canada and about one-third of that in France and Japan, while the electricity consumption per unit area of buildings in China is one-third of that in the US and Canada. The difference in lifestyle and building operation is one of the main reasons for the difference in electricity use intensity between China and developed countries.

In recent years, the carbon emission increase caused by the growth in electricity consumption of buildings has exceeded the carbon emission decrease resulting from the reduction of the carbon emission factor of electricity. The indirect carbon emissions from electricity consumption of buildings will keep increasing before peaking. China should maintain a green and economical lifestyle and building operation mode to avoid any surge in energy use of buildings that once occurred after rapid economic growth in the history of the US, Japan, and other developed countries. When the building floor area in China reaches 75 billion m2 in 2060, the electricity consumption of buildings should be 3.8 PWh, which will meet the demand of the Chinese people for a good life and energy consumption of buildings. On this basis, the new type of electric power system adopting “photovoltaic, energy storage, direct current and flexibility (PEDF)” technologies should be promoted. When the reduction in indirect carbon emissions from building electricity use caused by the increase of “green electricity” in practical electricity consumption through flexible electricity use is greater than the growth in indirect carbon emissions from building electricity use caused by the growth in the total scale and electricity use intensity of buildings each year, the indirect carbon emissions from the electricity use of buildings in China can peak. Upon overall popularization of the “PEDF” power distribution mode and flexible means of electricity use, the zero-carbon goal for electricity consumption of buildings can be achieved earlier than that for the national power system.

-

(3)

Indirect Carbon Emission from Heating

In 2021, the building floor area of NUH in China was 16.2 billion m2, and the indirect carbon emission from heating during building operation was 430 million tons of CO2. Recent years have seen continuous growth in the centralized heating area and heating demand in northern China but a continuous decrease in energy consumption and carbon emissions per square meter of heat supply. The total indirect carbon emissions from NUH showed a trend of slow growth. The indirect carbon emissions from heating during building operation can peak by around 2025 through further strengthening the renovation of existing buildings, fully exploiting low-grade residual heat resources, and phasing out scattered coal-fired boilers. Afterward, with the gradual completion of the zero-emission transformation of the remaining thermal power (to be replaced with CCUS and biomass fuel) by the electric power sector, the indirect carbon emissions from building heating can be reduced to zero in sync with the decarbonization process of the power system.

To this end, it is necessary to continue improving the envelope performance of new buildings and the renovation of existing buildings in a strict manner, so that the average heating demand of buildings in northern China can decrease from 0.37 GJ/m2 at present to below 0.25 GJ/m2. During 2020–2035, the return water temperature should be lowered through the terminal renovation of centralized heating systems, thus effectively recovering the residual heat of thermal power plants and the industrial low-grade residual heat. The increasing building heating demand will be met by tapping into the potential heating capacity of existing heat sources. CHP transformation will be carried out for the coastal nuclear power in northern China to supply heat to areas within 200 km from the normal of coastal northern China. From 2035, in coordination with the schedule of the thermal power shutdown of the electric power system, seasonal heat storage projects will be implemented simultaneously to solve the problem of reduced heat source power resulting from the shutdown of thermal power plants. Until 2045, the annual residual heat of nuclear power, the annual residual heat of peak shaving thermal power, the residual heat of wind and solar curtailments at the centralized wind and solar PV power bases, as well as the heat emitted annually from the industrial low-grade residual heat will have been collected through seasonal heat storage projects. In this way, the indirect carbon emissions from building heating can be reduced to zero, while zero-carbon emission of the power system is realized.

In view of the four categories, the scale, intensity, and total quantity of carbon emissions from them are represented in the block diagram in Fig. 1.13 respectively, in which the horizontal axis stands for the building floor area and the vertical axis for carbon intensity per square meter for the four categories. The total area of the four blocks represents the total carbon emissions. The growth in the total carbon emissions from the four categories is shown in Fig. 1.14. It can be seen that the characteristics of carbon emissions from the four categories are not the same as those of their energy consumption. As public and commercial buildings have the highest energy use intensity, their carbon intensity per unit area is also at the peak. In 2021, their carbon intensity was 48.9 kg CO2/m2, and their total carbon emissions were still on the rise as their total energy consumption and energy use intensity were growing steadily. For NUH, its carbon intensity was only second to that of public and commercial buildings due to the consumption of a lot of coal. In 2021, the carbon intensity was 29.7 kg CO2/m2, and the carbon emissions peaked and remained stable at approximately 0.5 Gt CO2 due to the increasing heat demand, the improvement of heat supply efficiency, and the consistent speed in the transformation of energy structure. Although there is little difference in primary energy use intensity per square meter between rural and urban residential buildings, the carbon intensity per square meter of rural residential buildings is higher than that of urban residential buildings due to a low level of electrification and a high proportion of coal fuel. The carbon intensity per unit area of rural residential buildings was 21.7 kg CO2/m2. Due to the implementation of “switching from coal to electricity” and “switching from coal to gas” in rural areas, the total carbon emissions of rural residential buildings have peaked and then declined annually in recent years. The carbon intensity per unit area of urban residential buildings was 16.4 kg CO2/m2 and was increasing slowly with the growth in electricity consumption.

1.3.4 Embodied CO2 Emission of Building Sector

As urbanization continues, the embodied energy use of civil buildings in China also increases rapidly. The construction of buildings and infrastructures not only consumes a colossal amount of energy but also leads to a lot of carbon dioxide emissions. In addition to carbon dioxide emissions resulting from energy consumption, emissions in the cement production processFootnote 7 are also an important part.

In 2021, the total carbon emissions from civil building construction in China were about 1.6 Gt CO2, mainly including carbon emissions from energy use for the manufacturing and transportation of building materials (77%), the industrial process emissions of cement (20%) and energy use during construction (3%), as shown in Fig. 1.15. Although such carbon emissions are included in the industry and transportation sectors, they are driven by the demand of the building sector. Hence, the building sector shall also be responsible for such carbon emissions and reduce its demand to contribute to emission reduction. With the end of the large-scale construction period in China, the scale of newly built building stock has been decreasing each year. The carbon emissions from civil building construction peaked in 2016 and have been declining slowly year by year in recent years. The scale of newly built building stock declined markedly in 2020 due to the impact of COVID-19 and rebounded in 2021 as the pandemic in China was getting better. As a result, the embodied carbon emissions of civil buildings fell heavily in 2020 and rose again in 2021.

In fact, as China is still in the urbanization stage, various infrastructures need to be constructed in addition to civil buildings. In 2021, the total carbon emissions from construction in the construction sector were about 4.1 Gt CO2, nearly half of China’s total carbon emissions, as shown in Fig. 1.16. Carbon emissions from civil building construction were about 40% of the total carbon emissions from construction in China’s construction sector.

To realize zero carbon emissions from building construction as early as possible, the total number and scale of buildings should be controlled reasonably first to minimize excessive construction and avoid large-scale demolition and construction. At present, the total building stock and per capita floor area in China have met the demands of urban and rural residence, production, and living. By 2060, the production and living demands of the future urban and rural populations in China can be met with 40 m2 of per capita residential floor area, 15.5 m2 of per capita P&C building stock, and 75 billion m2 of total floor area. To realize zero-carbon emissions from building construction in China, the construction speed, total quantity, and scale of buildings need to be planned rationally.

In the meantime, China’s construction sector will shift from the large-scale construction of new buildings to the maintenance and functional improvement of existing ones. The construction of houses in China has shifted from increasing the supply of houses to meet immediate needs to demolishing old ones and building new ones to improve building performance and functionality. The “Mass-Demolition-for-Mass-Construction” pattern has become the main mode of the construction sector. Based on the objective of total number planning for civil buildings in the future and in view of the reasonable construction speed, the gradual transformation from “Mass-Demolition-for-Mass-Construction” to “replacing demolition with fine repair” will enable the stabilization of China’s construction sector and the gradual reduction of carbon emissions from civil building construction to 0.2 Gt CO2. Zero emissions from building construction are expected to be realized in 2050 through further application of new building materials and new structural systems and technologies.

Notes

- 1.

Xiaojiang Li, Degao Zheng. Characteristics of the Urbanization of Population and Formation of the National Urban System.

- 2.

Source: China Urban-Rural Construction Statistical Yearbook (2006–2021), Ministry of Housing and Urban-Rural Development of the People’s Republic of China.

- 3.

The newly built building stock data is based on the data under “the statistical standards for construction enterprises as specified in the China Statistical Yearbook on Construction”.

- 4.

Data about the consumption of building materials is from the China Statistical Yearbook on Construction.

- 5.

Materials for the construction sector here mainly include steel, cement, aluminum, glass and architectural ceramics.

- 6.

Refers to gas- and coal-fired heating boilers installed in urban and rural residential buildings as well as coal- and gas-fired boilers installed in public and commercial buildings. Such fuels are burned directly in buildings, so the resulting carbon emissions fall into the category of direct carbon emissions from buildings.

- 7.

Refers to carbon emissions from chemical reactions (excluding combustion) for cement production.

Author information

Authors and Affiliations

Consortia

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License (http://creativecommons.org/licenses/by-nc-nd/4.0/), which permits any noncommercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if you modified the licensed material. You do not have permission under this license to share adapted material derived from this chapter or parts of it.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2024 Building Energy Research Center of Tsinghua University

About this chapter

Cite this chapter

Building Energy Research Center of Tsinghua University. (2024). China’s Building Energy Use and GHG Emissions. In: Decarbonize Urban Heating System . Springer, Singapore. https://doi.org/10.1007/978-981-99-7875-5_1

Download citation

DOI: https://doi.org/10.1007/978-981-99-7875-5_1

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-7874-8

Online ISBN: 978-981-99-7875-5

eBook Packages: EngineeringEngineering (R0)