Abstract

Aiming at the problem of comprehensive detection technology and treatment measures for tunnels crossing large karst caves, this paper systematically carried out the research on advanced detection of karst geology and treatment measures of karst caves in combination with the Qinlan Tunnel Project of Tianba Expressway in Guangxi. The comprehensive detection method of “karst geological survey + geological radar detection + advanced horizontal drilling + three-dimensional laser scanning + geological sketch” is used for advanced detection. On the basis of ascertaining the spatial location and development scale of karst caves, the scheme of tunnel excavation after advanced reinforcement and support treatment such as advanced small pipe grouting is determined. It has been successfully applied to the construction practice of Qinlan Tunnel crossing ZK89+110 large karst caves, and the treatment measures of “root pile + lining strengthening” are put forward. It effectively avoids the occurrence of disasters caused by karst caves, and has important reference significance for similar projects.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Karst is a general term for the chemical effects of water on soluble rocks, supplemented by mechanical effects such as erosion, deposition and collapse, and the phenomena caused by these effects. Karst geology is widely distributed in China, mainly concentrated in Yunnan, Sichuan, Guangxi, Guizhou and other regions [1]. Due to the complexity of karst geology and high risk of karst caves, tunnel construction faces great risks and challenges [2]. During the construction of Maluqing Tunnel [3], Yuanliangshan Tunnel [4] and Xiaogaoshan Tunnel of Shanghai-Kunming Passenger Dedicated Railway [5], karst water and mud inrush disasters occurred, causing serious casualties and economic losses. Therefore, the use of advanced detection technology to accurately identify the spatial location and development scale of karst caves can effectively ensure the safety of karst tunnel construction.

At present, researchers have conducted many studies on karst tunnel advanced geological prediction technology and cave treatment. Zhao Shaozhong et al. studied the deformation law of surrounding rock by numerical simulation method and gave the treatment measures of karst cave in different positions, combining with the karst cave exposed in the construction of Qiyueshan tunnel [6]. Wang Shaohui et al. proposed a comprehensive treatment scheme for the combined structure of “bearing pile foundation-longitudinal and transverse frame beam structure-reinforced concrete retaining wall” in view of the extra-large karst cave exposed during the construction of Naqiu Tunnel [7]. Liu Tongjiang et al. determined the treatment scheme of “backfill ballast + upper grouting reinforcement” for the giant karst cave crossed by the alpine tunnel of Qian-Zhang-Chang railway [8]. Based on the engineering background of Shangjiawan tunnel, Li Shucai et al. proposed the cave treatment scheme of “beam plate method + backfill method” [9]. Wang Jian et al. used the geological radar advanced geological prediction method to detect the karst development of Xinjie Tunnel of Guizhou Kaili Ring Expressway, and verified the applicability of the method [10]. Combining with Yesanguan tunnel of Yiwan railway, Sun Mingbiao put forward the treatment measures such as high level drainage depressurization, curtain grouting and pipe shed pre-support, which realized the purpose of depressurization, reinforcement and seepage prevention [11]. Based on the Taiping Tunnel of Xuanhe Expressway, Liu et al. proposed a variety of technical schemes for crossing karst caves and determined the double-arch open-cut tunnel + backfill excavation scheme through multi-dimensional comparison and selection [12].

Based on Qinlan Tunnel Project of Tianba Expressway, aiming at the problem of karst disaster in the process of tunnel excavation, this paper carries out karst detection by using comprehensive means such as geological advance prediction, advance drilling and three-dimensional laser scanning. On the basis of ascertaining the spatial location and development scale of karst caves, this paper puts forward targeted treatment measures for karst caves.

2 Engineering Overview

Qinlan Tunnel is located in Hechi City, Guangxi. The overall direction of the tunnel is east–west, and the tunnel is a small clearance + separate special long tunnel. The starting and ending pile numbers of the left line of the tunnel are ZK86+164~ZK91+486, and the length is 5322.0 m. The starting and ending piles of the right line are K86+190~K91+494, and the design length is 5304.0 m. The tunnel is a two-way six-lane tunnel with a maximum buried depth of about 356.67 m. The overall view of the tunnel is shown in Fig. 1.

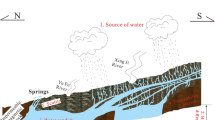

The stratas are mainly the Fourth Series Dissolution Remnant Accumulation Layer (Qcl) and the Carboniferous Middle System (C2) strata. The tunnel mainly passes through the Carboniferous Middle System (C2) limestone, with cryptocrystalline ~ microcrystalline structure and layer thickness ~ huge thick layered structure. The rock is hard and there are karst caves developed locally. The tunnel area belongs to karst peaks and depressions, with strong mountain erosion and exposed bedrock. The ground elevation of the karst depression on the entrance side of the cave entrance is 350–370 m. And there are springs and sinkholes in the low-lying areas.

Groundwater types can be divided into loose rock pore water, clastic rock fracture water and carbonate fracture karst water. Karst in the tunnel area is relatively developed. The main karst forms are karst caves, gullies and dissolution depressions. Trenches are mostly filled with clayey soil of the fourth series residual slope layer. During the construction period, a very large cave was revealed at ZK89+110 (see Fig. 2), with a height of about 60 m. It develops from the right to the lower left, crosses diagonally with the tunnel axis, and invades the left vault range of the right cave.

3 Joint Detection and Analysis of Caves

A variety of detection methods were used to detect and analyze the cave at ZK89+110.

3.1 Geological Radar Method

The geological radar method works according to the principle of pulsed radar emission waves. High-frequency electromagnetic waves are sent underground in the form of broadband short pulses through the transmitting antenna. It was reflected by underground media or buried objects, which was received by the receiving antenna and recorded on the host to form a radar profile [13]. The geological radar YQZLS20112 was used to detect the tunnel of ZK89+095~ZK89+125 in the left cave, and the schematic diagram of the survey line layout was shown in Fig. 3.

The detection results show that the surrounding rock of ZK89+095~ZK89+120 section is mainly moderately weathered limestone, with medium and thick layered structure. The joints and dissolution fractures are relatively developed, mostly filled with calcite veins or argillaceous. The surrounding rock of ZK89+120~ZK89+125 section is affected by joint fractures, and the rock is loosely broken, filled with mud and mud. And dense fracture zone or karst development area is developed. The processed image of the acquired waveform is shown in Fig. 4.

3.2 Advanced Horizontal Drilling

Advanced horizontal drilling is a short-range tunnel surrounding rock geological prediction technique. A horizontal drilling rig is installed inside the tunnel and drilled to infer the geology in front of the palm according to the drilling data [14]. ZDY1250 full-hydraulic multi-functional crawler drilling rig was used to carry out geological advanced drilling work on the face ZK89+035 of the second half of the tunnel in Qinlan. Five drill holes were arranged on the face of the face. And the location of the drilling hole arrangement is shown in Fig. 5.

Three advanced drill holes were completed and the geotechnical characteristics revealed by each hole are shown in Fig. 6. It shows that there are clay-filled karst caves in the ZK89+108.4~ZK89+111.3 section of the tunnel. The karst cave has not been uncovered, and the total length of the karst cave section is more than 2.9 m. The rock mass around the cave is relatively complete limestone and locally broken limestone. Karst development is strong, and the stability of surrounding rock is poor. After excavation, mud gushing, block falling, cavity collapse, roof falling and other phenomena are prone to occur, and groundwater is weakly developed.

3.3 3D Laser Scanning Technology

Through the high-speed non-contact laser measurement method, the three-dimensional laser scanning technology can carry out 360° panoramic rapid scanning of complex objects in three-dimensional space. We can obtain the three-dimensional shape of the object to guide the construction of the project [15]. The cave was scanned by 3D laser scanning technology and its three-dimensional morphology was obtained (see Fig. 7). The results show that the large karst cave is exposed in front of the ZK89+110 face. The karst cave crosses the tunnel obliquely and intrudes into the right tunnel K89+130~K89+210 of the back section of Qinlan tunnel. The surrounding rock is mainly silty clay, which has poor stability and it is prone to collapse without support. There are many sinkholes and 2 water-dissipation caves.

4 Cave Treatment Measures

This project selects the root pile + lining strengthening scheme. The treatment facade of ZK89+110 karst cave is shown in Fig. 8. The specific design is as follows.

-

(1)

First, remove the cave floor slag and silt layer. Then investigate the direction of water flow in karst cave, water dissipation tunnel, etc.

-

(2)

The ZK89+100~ZK89+170 section of the karst cave is lined with S5-P. Cave internal system anchor can be canceled. The advanced support adopts the dense row of advanced small ducts. The length of the advanced small duct is 4 m, the circumferential spacing is 40 cm, and the longitudinal row spacing is 1 m. The locking feet support on both sides of the arch line is replaced by a 9 m long Φ108*6 mm locking foot steel pipe with a longitudinal spacing of 1 m. It is staggered with Φ50*5 mm locking steel tube.

-

(3)

The foundation of the K89+130~K89+205 section of the inverted arch is reinforced by a composite foundation of tree root stumps. The root pile is 20 cm in diameter and it is plum-shaped layout. The specific design scheme is shown in Fig. 9.

-

(4)

The cave is treated by pumping concrete. The vault and the cavity at the waist are pumped first. Then 60 cm thick reinforced concrete was poured on the vault range. Finally, pour the concrete drainage ditch.

5 Conclusion

With the large karst cave crossed by Tianba highway Qinlan tunnel, this paper studies the comprehensive detection and treatment measures of large karst cave crossed by tunnel. The main conclusions are as follows.

-

(1)

Aiming at the large karst caves traversed by the tunnel, the comprehensive detection method of “karst geological survey + geological radar detection + advanced horizontal drilling + three-dimensional laser scanning + geological sketching” is proposed for advanced detection.

-

(2)

On the basis of finding out the location and development scale of karst cave, the scheme of tunnel excavation after advance reinforcement support treatment such as advance small pipe grouting is determined, which ensures that the Qinlan tunnel passes through ZK89+110 large karst cave safely.

-

(3)

In this paper, the comprehensive treatment scheme of “comprehensive detection + advanced small pipe support + grouting reinforcement + root pile composite foundation reinforcement + lining reinforcement” is adopted. The problem of tunnel crossing karst cave treatment measures has been successfully solved, which provides an effective reference for similar projects in the future.

References

Ren R, Bai WZ, Gong LJ (2018) Study on detection and treatment technology of Karst Cave in highway tunnel. Road Constr Mach Constr Mech 10:79–83

Sun JT, Li ZT, Yuan JQ, Xiao DH (2021) Comprehensive advance detection and treatment technology for tunnels passing through large infilled Karst Caves. Mod Tunn Technol S1:416–425

Yang B (2011) Treatment techniques for Karst disaster of Maluqing Tunnel on Yichang-Wanzhou Railway. Chin J Underground Space Eng 03:581–586

Liu ZW, He MC, Wang SR (2006) Study on Karst waterburst mechanism and prevention countermeasures in Yuanliangshan tunnel. Rock Soil Mech (02):228–232+246

Zhang HG, Zhang GZ, Mao BY (2016) Mechanism analysis and water and mud breakout in the Xiaogao Mountain tunnel in Shanghai-Kunming passenger dedicated railway. J Railway Eng Soc (08):66–70+84

Zhao SZ, Huang X, Xu ZH, Li MH (2022) Development characteristics and treatment techniques of Karst Caves in Qiyueshan Tunnel. Tunn Constr 07:1289–1299

Wang SH, Chen Z, Jiang C et al (2017) Comprehensive treatment scheme and construction technology of super large karst tunnel. Tunn Constr 06:748–752

Liu TJ, Tang G, Wang J, Sun YF (2019) Treatment technology of Giant Karst Cave of Gaoshan Tunnel on Qianjiang-Zhangjiajie-Changde Railway. Tunn Constr 06:972–982

Li SC, Zhou ZQ, Ye ZH et al (2015) Comprehensive geophysical prediction and treatment measures of karst caves in deep buried tunnel. J Appl Geophys 116:247–257

Wang J, Wang LJ, Ma JX, He X (2020) Karst investigation and the countermeasures in Xinjie Tunnel of the Kaili Ring Highway, Guizhou Province. Geotech Eng Tech (05):276–281+285

Sun MB (2010) 602 Karst Cave Treatment in Yesanguan Tunnel on Yichang-Wanzhou Railway. Mod Tunn Technol 01:91–98

Liu XB, Wang LC, Wang YN (2022) Construction and treatment technologies of highway tunnel crossing super-large caves: a case study of Taiping tunnel project. Mod Tunn Technol S1:892–902

Cheng QJ (2020) Research on advanced detection and treatment technology of karst cave in tunnel. Highway 05:357–362

Nong J (2016) Study on Highway tunnel advanced level forecast drilling parameters of power ratio and wavelet analysis. Chang’an Univ 02:1–2

Hou GP (2021) Research on data processing method of tunnel deformation point cloud based on 3D laser scanning. Southwest Jiaotong Univ 05:6–8

Acknowledgements

Authors wishing to acknowledge the financial support from the Science and Technology Project of Gansu Province (21YF5FA002), and the Basic Research Program of Natural Science from Shaanxi Science and Technology Department (Grant No. 2022JM-191).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Wang, X., Zhou, Y., Zhang, G., Chen, X., Liu, Z., He, X. (2023). Study on Comprehensive Detection and Treatment Measures of Qinlan Tunnel of Tianba Expressway Crossing Large Karst Cave. In: Wang, S., Li, J., Hu, K., Bao, X. (eds) Proceedings of the 2nd International Conference on Innovative Solutions in Hydropower Engineering and Civil Engineering. HECE 2022. Lecture Notes in Civil Engineering, vol 235. Springer, Singapore. https://doi.org/10.1007/978-981-99-1748-8_32

Download citation

DOI: https://doi.org/10.1007/978-981-99-1748-8_32

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-1747-1

Online ISBN: 978-981-99-1748-8

eBook Packages: EngineeringEngineering (R0)