Abstract

In order to evaluate the cost of each stage of the one through fuel cycle (OTC), the uranium required for each stage of the OTC is calculated in detail based on the equilibrium mass flow. According to the material flow analysis, front-end cost and back-end cost of the nuclear fuel cycle under different discount rates are analyzed according to the material flow. The results show that the front-end cost increases with the discount rate, while the back-end cost decreases with the discount rate, and the front-end cost is higher than the back-end cost. The three stages of natural uranium, uranium enrichment and fuel manufacturing not only account for a large proportion of the total cost, but also have a strong sensitivity. Among them, the cost of uranium enrichment has the greatest impact on LCOE, followed by the cost of natural uranium.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

According to the latest statistics of the world nuclear association, about 11% of the world’s electricity comes from about 450 nuclear power reactors. At present, more than 60 reactors are under construction, equivalent to 16% of the existing capacity. It is estimated that China’s uranium demand will be about 18500tU in 2025, and about 130 reactors will operate to 24000tU in 2030 [1]. By the end of 2021, 53 commercial units in mainland China have been used for an average of 3546.6 h, and the utilization rate of units has reached 81.6% on average.

At present, there are three main types of nuclear fuel cycle strategies implemented by countries around the world. The first type is one cycle, which is characterized by the direct geological treatment of spent fuel unloaded from the reactor after cooling. This cycle method is widely used because of its simple process and no risk of nuclear proliferation; The second type is the recycling of uranium and plutonium, which is mainly represented by MOX fuel. This cycle method cools the UOX spent fuel discharged from the thermal reactor and extracts uranium and plutonium, and then mixes Pu and UO2 to make MOX fuel. Compared with one cycle, the recovery of uranium and plutonium improves the utilization rate of uranium resources; The third type is to introduce fast reactor to realize the utilization of transuranium elements. This cycle truly realizes the effective utilization of uranium resources, but it is seldom implemented at present due to the lack of commercial technology and complex process. In the foreseeable future, China will mainly focus on primary recycling, uranium and plutonium recycling and the utilization of transuranium elements through fast reactors.

The large-scale use of nuclear power has also brought another focus of attention, that is, the economy of nuclear power. In the economic analysis of nuclear power, the cost required by the fuel cycle is an important part. The cost analysis of each stage of the fuel cycle can not only find the part that has a greater impact on the total cost, but also control the cost of each stage according to the sensitivity to realize the economy of nuclear power. To intuitively understand the cost of each stage of the nuclear fuel cycle, this paper calculates the material flow of each stage in the typical PWR Fuel one-time pass scheme, and calculates the relevant levelized cost according to the material flow.

2 Characteristics and Material Flow Analysis of Nuclear Fuel Cycle

2.1 One Through Fuel Cycle Feature

Nuclear fuel cycle refers to the whole process from uranium ore mining, uranium conversion and enrichment to fuel production and fuel recycling or geological disposal after irradiation in the reactor. Generally, uranium ore mining and processing, uranium conversion to UF6, UF6 enrichment and fuel element manufacturing are divided into the front end of the cycle. The irradiation of fuel elements in the reactor is called the irradiation stage, the spent fuel discharged from the reactor is temporarily cooled and finally disposed of in geology or extracted from uranium and plutonium, which is called the back end of the cycle [2].

The irradiated nuclear fuel in the reactor is usually called spent fuel. There are two main ways to treat it after cooling: one is conventional geological treatment, and the other is the separation and recycling of actinides [3]. In the first way, the radioactivity of spent fuel will continue to exist for more than hundreds of thousands of years after storage. Therefore, not only a special repository is required, but also it must be ensured that the radioactive and/or toxic elements in spent fuel will not leak for such a long time, causing harm to the surrounding environment and public safety. At the same time, various problems faced by the public acceptance must be considered.

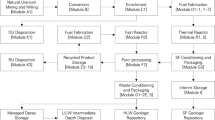

The nuclear fuel cycle is divided into different cycle types according to the treatment methods of spent fuel. At present, many countries adopt the one through fuel cycle (OTC) scheme, and its cycle flow is shown in Fig. 1. The OTC scheme has a simple and short process, but the utilization rate of uranium resources is relatively low, and the amount of waste for subsequent treatment is relatively large.

Another popular cycle scheme is to recover uranium and plutonium from spent fuel and make it into MOX fuel. This cycle scheme is also known as the twice through fuel cycle (TTC). In addition to conventional UOX fuel, the reactor can also be loaded with MOX fuel. The preparation, application and post-treatment of MOX fuel is one of the key technologies of the closed fuel cycle. The utilization of uranium resources can be significantly improved by recycling uranium and plutonium in UOX spent fuel. Research shows that using MOX fuel in thermal reactor can improve the utilization rate by 20%–30%. If it is used in fast reactor, the utilization rate can be increased by 20 times.

The separation of uranium and plutonium in spent fuel is conducive to reducing the radioactivity, volume of spent fuel and the time required for radioactivity to return to the natural level, and minimizing the harm to the environment and human health caused by long-term storage of radioactive substances. Compared with the TTC scheme, the OTC scheme is not a true fuel cycle in the sense of geological disposal of spent fuel directly.

2.2 Equilibrium Material Flow Analysis

Material flow is the basis for calculating the levelized power generation cost. In this paper, assuming that the nuclear fuel meets the mass conservation during the cycle, the annual reactor loading M can be calculated according to the following formula [4]:

where: M is the annual fuel quantity required by the nuclear power plant (tHM/a); Pe is the electric power of reactor (GWe); CF is the capacity factor or load factor of the reactor; \(\varepsilon\) is the thermal efficiency of the reactor (%); Bd is burnup depth (GWd/tHM).

By calculating the amount of fuel required by the nuclear power plant each year, the mass of natural uranium required and the required separation work can be calculated according to the following two formulas.

where: Mnat is the annual natural uranium demand of the reactor (tHM/a); F is the mass of natural uranium in the enrichment feed (tHM/a); P is the quality of uranium enrichment product (tHM/a); Xp is the concentration of U235 in enriched uranium products (%); Xnat is the concentration of U235 in natural uranium (%); Xt is the concentration of U235 in depleted uranium tailings (%); R is the utilization rate of uranium at each stage (%); S is the separation work (SWU). The mass inflow and outflow diagram of each stage of material flow calculation is shown in Fig. 2.

At present, the mainstream commercial reactor types in China not only consider the Fukushima nuclear power accident, but also integrate the international advanced three generation nuclear power idea. They shoulder an important mission both at home and abroad. Therefore, this paper selects the design parameters of the mainstream nuclear power reactor types at this stage for calculation, as shown in Table 1 below.

To calculate the cost of each phase of the fuel cycle, the mass of each part of the cycle must be provided. According to the above introduction, the balance materials of each cycle component can be calculated as shown in Table 2 below:

3 Calculation Results and Discussion

Price information is not only a necessary condition for levelized cost calculation in each cycle stage, but also a judgment standard for accuracy in economic calculation and analysis. However, because different countries have different policies and different calculation methods, some costs, such as the price of natural uranium, will change with the passage of time and the relationship between countries, so it is difficult to accurately calculate the absolute value of each stage. The unit cost used in this paper is the average value in recent years. At the same time, the upper limit and lower limit are taken as the upper and lower limit according to the 20% fluctuation of the average value.

3.1 Levelized Cost Analysis

The total cost of a simple nuclear fuel cycle can be calculated by multiplying the fuel required at each stage of the cycle by the unit cost. However, as the whole cycle of nuclear fuel is long, reaching several decades, the time factor needs to be considered. Levelized cost is a commonly used method for economic analysis of energy and power industries. Considering the technical differences, the evaluation of different energy costs is particularly appropriate. In this paper, the levelized cost of energy (LCOE) is used to evaluate the economic benefits of each stage. The calculation method is as follows:

where: T is the annual score, and r is the discount rate.

The concentration of natural uranium (0.711%) is far less than that of U in fuel elements of nuclear power plants (4.45%), so it is necessary to enrich natural uranium and convert it into UF6. The price of natural uranium is affected by the military strategy and trade between countries and the global inventory, and often shows an irregular change trend, so it is difficult to accurately quantify it. Therefore, this paper selects the average price of UxC company in recent months of 57.3 USD/kg, the price of uranium conversion is 9.5 USD/kg, and the unit price of uranium enrichment is 140 USD/SWU. According to the OECD/NEA 2006 report, the production price of fuel elements is 285 USD/kg.

The cost of temporary storage and final geological disposal of spent fuel includes overnight cost, operation and maintenance cost and decommissioning cost. These costs are difficult to estimate, mainly due to the lack of reference information for commercial operation. Cameron R [5] has calculated the cost of each part in detail and made corresponding analysis. Therefore, this paper has made corresponding fitting for the temporary storage and geological disposal of spent fuel according to the results of Cameron R. finally, the unit price of spent fuel cooling and temporary storage is 200 USD/kg, and the unit price of spent fuel transportation and geological disposal is 412 USD/kg. The fitting results are basically consistent with the research results of MIT [6].

According to the above relevant parameter analysis and OTC cycle time interval Table 3, the cost of each part of the nuclear fuel cycle can be calculated when the discount rate is 0%, 2% and 4%, as shown in Table 4.

It can be seen from Table 4 that the selection of discount rate affects not only the total levelized cost, but also the cost of each stage. For OTC fuel cycle of nuclear power plant, the front levelized fuel cost increases with the increase of discount rate, and the back levelized fuel cost decreases with the increase of discount rate. In addition, it can be seen from Table 4 that the front-end levelized cost of the nuclear fuel cycle is greater than the rear end levelized cost. Among the total costs, the purchase of natural uranium, uranium enrichment and fuel production account for the largest proportion. When the discount rate is 4%, the purchase of natural uranium accounts for 28%, uranium enrichment accounts for 46% and fuel production accounts for 13%.

Figure 3 shows the cost accumulation diagram of the nuclear fuel cycle corresponding to different discount rates. It can be clearly seen from Fig. 3 that with the increase of the discount rate, the total cost of the nuclear fuel cycle gradually decreases. In particular, the cost required for geological disposal decreases significantly, and the cost required for fuel production and uranium conversion does not change significantly.

3.2 Sensitivity Analysis

In order to further analyze the impact of each stage of the nuclear fuel cycle on the total LCOE, this paper selects the impact of 20% of each unit price change on the total cost when the discount rate is 2%, as shown in Fig. 4 below.

As can be seen from Fig. 4, the four factors that have a greater impact on LCOE are the cost of enriched uranium, the cost of natural uranium, the cost of spent fuel disposal and the cost of fuel production. Among them, the cost of uranium enrichment has the greatest impact on LCOE, followed by the cost of natural uranium, which shows that the cost of uranium enrichment and natural uranium play an important role in the nuclear fuel cycle. As the price of natural uranium is greatly affected by the strategies of various countries, with the extensive use of nuclear energy in China’s energy layout, the economy of nuclear power can be better guaranteed only when the supply of uranium resources is stable.

In addition, 95% of the spent fuel is composed of uranium and plutonium, so these elements can be separated and converted into MOX fuel for recycling. The separation and transmutation of spent fuel can not only increase the service life of nuclear elements, but also greatly reduce the risk caused by long-term storage, reduce the impact of radioactive elements on the environment and public health, and alleviate the supply of natural uranium to a certain extent.

4 Conclusions

Based on the material flow and economic analysis, this paper makes a detailed calculation on the cost of nuclear fuel passing through each stage at one time, and mainly draws the following conclusions:

Although the OTC scheme of the nuclear fuel cycle is simple and easy to operate, the utilization rate of uranium in the fuel is low. In terms of the cost of the cycle, the front-end cost is greater than the back-end cost, and the front-end cost increases with the increase of the discount rate, while the back-end cost decreases with the increase of the discount rate. The sensitivity analysis further shows that the cost of uranium enrichment, the cost of natural uranium and the manufacturing cost of fuel not only account for a large proportion of the total cost, but also have strong sensitivity.

To further reduce the total cost of the nuclear fuel cycle, it is necessary not only to reduce a large proportion of the cost of the cycle, but also to improve uranium enrichment and fuel production technology through technological innovation. In the future, when optimizing the fuel cycle, designers can improve the enrichment of fuel, increase fuel consumption, and reduce the enrichment of tailings. For the cost control of fuel assembly production process, it is necessary to focus on the cost of fuel assembly production and natural uranium procurement. At the same time, it should also focus on the recycling of spent fuel. The separation of uranium and plutonium at the back end of the nuclear fuel cycle can not only control and minimize the harm to the environment and human health caused by long-term storage of radioactive substances, it can also improve the sustainability of nuclear energy. Finally, as the recovery of spent fuel involves the recovery of plutonium, we should also pay attention to the impact of technical, environmental and political factors on the nuclear fuel cycle strategy while considering the economy.

References

World Nuclear Association, Nuclear Power in the World Today (Updated May 2021). http://www.world-nuclear.org/information-library/country-profiles/countries-a-f/china-nuclear-fuel-cycle.aspx

Wu, Y., Wu, J., Mu, Q., et al.: Study on nuclear fuel cycle model of PWR in China before 2050. Nucl. Sci. Eng. 32(4), 371–378 (2012)

Hu, W., Jing, J., Pan X., et al.: Transmutation characteristics of secondary actinides in large advanced pressurized water reactor. Intense Laser Particle Beam 29(03), 29036016 (2017)

Ko, W.I., Gao, F.: Economic analysis of different nuclear fuel cycle options. Sci. Technol. Nucl. Installations 2012, 1–10 (2012)

Cameron, R., Urso, M.E., Lokhov, A.: The economics of the back end of the nuclear fuel cycle (2014)

Kazimi, M., Moniz, E.J., Forsberg, C.W., et al.: The Future of the Nuclear Fuel Cycle. Massachusetts Institute of Technology, Cambridge (2011)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Li, Z., Hu, J., Rong, M., Shang, X., Zhang, Y. (2023). Economic Analysis of the One Through Fuel Cycle Based on Equilibrium Mass Flow. In: Liu, C. (eds) Proceedings of the 23rd Pacific Basin Nuclear Conference, Volume 1. PBNC 2022. Springer Proceedings in Physics, vol 283. Springer, Singapore. https://doi.org/10.1007/978-981-99-1023-6_15

Download citation

DOI: https://doi.org/10.1007/978-981-99-1023-6_15

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-1022-9

Online ISBN: 978-981-99-1023-6

eBook Packages: Physics and AstronomyPhysics and Astronomy (R0)