Abstract

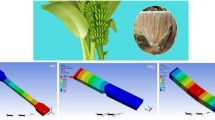

Bamboo is nowadays considered one of the most promising alternative substitutes to synthetic fibre composites. In addition to being affordable, having a quick growth cycle, being easily accessible, environmentally benign, extremely flexible, simple to develop, and biodegradable characteristics, it also has higher strength and stiffness with low density. Their natural abundance, lower cost, lightweight, and strength-to-weight ratio characteristics have compelled us to consider bamboo-reinforced composites as the most sustainable and suitable composites for wide industrial applications. Researchers are deeply involved in investigating such natural fibre-reinforced composites (NFRCs) for the wider arena of industrial applications that have identified their reliability and accessibility for being involved in aircraft, automotive, and marine equipment as well as in various engineering disciplines. In this regard, various researchers have gone through modelling and simulation approaches in order to determine the performance characteristics of such bamboo-reinforced composites (BRCs). The present work is a noble attempt to illuminate the readers regarding the comprehensive review and summary of the finite element method (FEM) approach that has been carried out in terms of their modelling and simulation (M&S), model type, simulation parameters, and performing platforms, their research outcomes based on the applicable theories and popular methods in this area. The work is also expected to let more experts know about the current status of research in this area which would definitely prove to be a resourceful work for sustainable guidance for relevant researchers.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Abhilash RM, Venkatesh GS, Chauhan SS (2021) Micromechanical modeling of bamboo short fibre reinforced polypropylene composites. Multiscale Multidiscip Model Exp Des 4(1):25–40. https://doi.org/10.1007/s41939-020-00081-3

Kim HG, Kwac LK (2009) Evaluation of elastic modulus for unidirectionally aligned short fibre composites. J Mech Sci Technol 23(1):54–63. https://doi.org/10.1007/s12206-008-0810-1

Ashwini K, Mohan Rao CV (2018) Design and analysis of leaf spring using various composites—an overview. Mater Today Proc 5(2):5716–5721. https://doi.org/10.1016/j.matpr.2017.12.166

Koronis G, Silva A, Fontul M (2013) Green composites: a review of adequate materials for automotive applications. Compos Part B Eng 44(1):120–127. https://doi.org/10.1016/j.compositesb.2012.07.004

AL-Oqla FM, Sapuan SM (2014) Natural fibre reinforced polymer composites in industrial applications: feasibility of date palm fibres for sustainable automotive industry. J Clean Prod 66:347–354, Mar 2014. https://doi.org/10.1016/j.jclepro.2013.10.050

Singh S, Deepak D, Aggarwal L, Gupta VK (2014) Tensile and flexural behavior of hemp fibre reinforced virgin-recycled HDPE matrix composites. Procedia Mater Sci 6:1696–1702. https://doi.org/10.1016/j.mspro.2014.07.155

Sailesh A, Arunkumar R, Saravanan S (2018) Mechanical properties and wear properties of Kenaf—Aloe Vera—Jute fibre reinforced natural fibre composites. Mater Today Proc 5(2):7184–7190. https://doi.org/10.1016/j.matpr.2017.11.384

Alves C et al (2010) Ecodesign of automotive components making use of natural jute fibre composites. J Clean Prod 18(4):313–327. https://doi.org/10.1016/j.jclepro.2009.10.02

Naresh Kumar S, Venkatesh D, Subbaratnam B, Shekar M (2020) Mechanical testing and numerical analysis of flax/glass epoxy hybrid composite material. IOP Conf Ser Mater Sci Eng 998(1). https://doi.org/10.1088/1757-899X/998/1/012032

Kiruthika AV (2017) A review on physico-mechanical properties of bast fibre reinforced polymer composites. J. Build. Eng. 9:91–99. https://doi.org/10.1016/j.jobe.2016.12.003

Mallampati M, Raju BN, Krishna TM (2018) Evaluation of mechanical properties of rice straw fibre polypropylene composites. AIP Conf Proc 1980:10–14. https://doi.org/10.1063/1.5044282

Madival AS, Doreswamy D, Handady SA, Hebbar KR, Lakshminarayana SK (2022) Investigation of the mechanical and liquid absorption properties of a rice straw-based composite for ayurvedic treatment tables. Materials (Basel) 15(2). https://doi.org/10.3390/ma15020606

Safri SNA, Sultan MTH, Jawaid M, Jayakrishna K (2018) Impact behaviour of hybrid composites for structural applications: a review. Compos Part B Eng 133:112–121. https://doi.org/10.1016/j.compositesb.2017.09.008

Vigneshwaran S et al (2020) Recent advancement in the natural fibre polymer composites: a comprehensive review. J Clean Prod 277:124109. https://doi.org/10.1016/j.jclepro.2020.124109

Ku H, Wang H, Pattarachaiyakoop N, Trada M (2011) A review on the tensile properties of natural fibre reinforced polymer composites. Compos Part B Eng 42(4):856–873. https://doi.org/10.1016/j.compositesb.2011.01.010

Fan J, Grande CD, Rodrigues DF (2017) Biodegradation of graphene oxide-polymer nanocomposite films in wastewater. Environ Sci Nano 4(9):1808–1816. https://doi.org/10.1039/C7EN00396J

Alvarez-valencia D, Dagher HJ, Roberto A, Davids WG, Gardner DJ (2009) Behavior of natural-fibre/thermoplastic sheet piling, pp 1–16

El-Sabbagh A, Taha I, Taha R (2011) Prediction of the modulus of elasticity of short fibre reinforced polymer composites by finite element modelling. Polym Polym Compos 19(9):733–742. https://doi.org/10.1177/096739111101900903

Xiong X, Shen SZ, Hua L, Li X, Wan X, Miao M (2018) Predicting tensile behaviors of short flax fibre-reinforced polymer–matrix composites using a modified shear-lag model. J Compos Mater 52(27):3701–3713. https://doi.org/10.1177/0021998318769128

Jagath Narayana K, Burela RG (2019) Multi-scale modeling and simulation of natural fibre reinforced composites (Bio-composites). J Phys Conf Ser 1240(1). https://doi.org/10.1088/1742-6596/1240/1/012103

Agarwal BD, Broutman LJ, Chandrashekhara K (1992) Analysis and performance of fibre composites (second edition). 151(1)

Chen XL, Liu YJ (2004) Square representative volume elements for evaluating the effective material properties of carbon nanotube-based composites. Comput Mater Sci 29(1):1–11. https://doi.org/10.1016/S0927-0256(03)00090-9

Sheng N, Boyce MC, Parks DM, Rutledge GC, Abes JI, Cohen RE (2004) Multiscale micromechanical modeling of polymer/clay nanocomposites and the effective clay particle. Polymer (Guildf) 45(2):487–506. https://doi.org/10.1016/j.polymer.2003.10.100

Schmachtenberg E, Brandt M (2006) Mechanical design of injection moulded parts made of short-fibre reinforced thermoplastics by means of integrative simulation. J Polym Eng 26(2–4), May 2006. https://doi.org/10.1515/POLYENG.2006.26.2-4.179

Facca AG, Kortschot MT, Yan N (2006) Predicting the elastic modulus of natural fibre reinforced thermoplastics. Compos Part A Appl Sci Manuf 37(10):1660–1671. https://doi.org/10.1016/j.compositesa.2005.10.006

Haghighat M, Zadhoush A, Khorasani SN (2005) Physicomechanical properties of α-cellulose-filled styrene-butadiene rubber composites. J Appl Polym Sci 96(6):2203–2211. https://doi.org/10.1002/app.21691

Affdl JCH, Kardos JL (1976) The Halpin-Tsai equations: a review. Polym Eng Sci 16(5):344–352. https://doi.org/10.1002/pen.760160512

Tucker CL III, Liang E (1999) Stiffness predictions for unidirectional short-fibre composites: review and evaluation. Compos Sci Technol 59(5):655–671. https://doi.org/10.1016/S0266-3538(98)00120-1

Budarapu PR, Zhuang X, Rabczuk T, Bordas SPA (2019) Multiscale modeling of material failure: theory and computational methods, 1st ed, vol 52. Elsevier Inc

Zhong B, Li C, Li P (2020) Modeling and vibration analysis of sectional-laminated cylindrical thin shells with arbitrary boundary conditions. Appl Acoust 162:107184. https://doi.org/10.1016/j.apacoust.2019.107184

Liu T, Wang A, Wang Q, Qin B (2020) Wave based method for free vibration characteristics of functionally graded cylindrical shells with arbitrary boundary conditions. Thin-Walled Struct 148:106580. https://doi.org/10.1016/j.tws.2019.106580

Gao W, Qin Z, Chu F (2020) Wave propagation in functionally graded porous plates reinforced with graphene platelets. Aerosp Sci Technol 102:105860. https://doi.org/10.1016/j.ast.2020.105860

Li C, Li P, Zhong B, Wen B (2019) Geometrically nonlinear vibration of laminated composite cylindrical thin shells with non-continuous elastic boundary conditions. Nonlinear Dyn 95(3):1903–1921. https://doi.org/10.1007/s11071-018-4667-2

Rahman MZ (2017) Mechanical performance of natural fibre reinforced hybrid composite materials using finite element method based micromechanmincs and experiments. J Chem Inf Model 53(9):1689–1699

Yu W (2016) An introduction to micromechanics. Appl Mech Mater 828:3–24. https://doi.org/10.4028/www.scientific.net/AMM.828.3

Poudel A (2019) Finite element method: introduction and steps of finite element analysis. https://geniuserc.com/finite-element-method-introduction-and-steps-of-finite-element-analysis/. Accessed on 25 Oct 2022

Abu Seman SAH, Ahmad R, Md Akil H (2019) Experimental and numerical investigations of kenaf natural fibre reinforced composite subjected to impact loading. Polym Compos 40(3):909–915, Mar 2019. https://doi.org/10.1002/pc.24758

Bazli M, Ashrafi H, Jafari A, Zhao XL, Raman RS, Bai Y (2019) Effect of fibres configuration and thickness on tensile behavior of gfrp laminates exposed to harsh environment. Polymers (Basel) 11(9):1401, Aug 2019. https://doi.org/10.3390/polym11091401

Chen Y, Xin L, Liu Y, Guo Z, Dong L, Zhong Z (2019) A viscoelastic model for particle-reinforced composites in finite deformations. Appl Math Model 72:499–512. https://doi.org/10.1016/j.apm.2019.03.033

Dong C (2019) Mechanical properties of natural fibre-reinforced hybrid composites. J Reinf Plast Compos 38(19–20):910–922. https://doi.org/10.1177/0731684419856686

Hu D, Dang L, Zhang C, Zhang Z (2019) Mechanical behaviors of flax fibre-reinforced composites at different strain rates and rate-dependent constitutive model. Materials (Basel) 12(6):854. https://doi.org/10.3390/ma12060854

Alioua T, Agoudjil B, Boudenne A (2019) Numerical modelling and experimental study of heat and moisture properties of a wall based on date palm fibres concrete. E3S Web Conf 85:02009, Feb 2019. https://doi.org/10.1051/e3sconf/20198502009

Su J, Zheng L, Deng Z (2019) Study on acoustic properties at normal incidence of three-multilayer composite made of glass wool, glue and polyurethane foam. Appl Acoust 156:319–326. https://doi.org/10.1016/j.apacoust.2019.07.016

Qin J-L, Qiao W-G, Lin D-G, Zhang S, Wang J-Y (2019) Mechanical properties and numerical analyses of basalt fibre crumb rubber mortars in soft rock roadways. Adv Civ Eng 2019:1–13. https://doi.org/10.1155/2019/5159094

Ma P, Jin L, Wu L (2019) Experimental and numerical comparisons of ballistic impact behaviors between 3D angle-interlock woven fabric and its reinforced composite. J Ind Text 48(6):1044–1058. https://doi.org/10.1177/1528083718754903

Sun X et al (2019) Fracture performance and numerical simulation of basalt fibre concrete using three-point bending test on notched beam. Constr Build Mater 225:788–800. https://doi.org/10.1016/j.conbuildmat.2019.07.244

Meyghani B, Awang MB, Emamian SS, Mohd Nor MKB, Pedapati SR (2017) A comparison of different finite element methods in the thermal analysis of friction stir welding (FSW). Metals (Basel) 7(10):1–23. https://doi.org/10.3390/met7100450

Frącz W, Janowski G (2019) Predicting effect of fibre orientation on chosen strength properties of wood-polymer composites. Compos Theory Pract 19(2):56–63

Jiang W-G, Zhong R-Z, Qin Q, Tong Y-G (2014) Homogenized finite element analysis on effective elastoplastic mechanical behaviors of composite with imperfect interfaces. Int J Mol Sci 15(12):23389–23407. https://doi.org/10.3390/ijms151223389

Adeniyi AG, Adeoye AS, Ighalo JO, Onifade DV (2021) FEA of effective elastic properties of banana fibre-reinforced polystyrene composite. Mech Adv Mater Struct 28(18):1869–1877. https://doi.org/10.1080/15376494.2020.1712628

Fragassa C (2016) Effect of natural fibres and bio-resins on mechanical properties in hybrid and non-hybrid composites, p 020118. https://doi.org/10.1063/1.4949693

George J, Sreekala MS, Thomas S (2001) A review on interface modification and characterization of natural fibre reinforced plastic composites. Polym Eng Sci 41(9):1471–1485. https://doi.org/10.1002/pen.10846

dos Santos D, Tavares LB, Batalha G (2012) Mechanical and physical properties investigation of polyurethane material obtained from renewable natural source. J Achieve Mater Manuf Eng 54(2):211–217

Vogtländer J, van der Lugt P, Brezet H (2010) The sustainability of bamboo products for local and Western European applications. LCAs and land-use. J Clean Prod 18(13):1260–1269. https://doi.org/10.1016/j.jclepro.2010.04.015

Asif M (2009) Sustainability of timber, wood and bamboo in construction. In: Sustainability of construction materials, Elsevier, pp 31–54

Manandhar R, Kim J-H, Kim J-T (2019) Environmental, social and economic sustainability of bamboo and bamboo-based construction materials in buildings. J Asian Archit Build Eng 18(2):49–59. https://doi.org/10.1080/13467581.2019.1595629

Sharma B, Gatóo A, Bock M, Ramage M (2015) Engineered bamboo for structural applications. Constr Build Mater 81:66–73. https://doi.org/10.1016/j.conbuildmat.2015.01.077

Huang Z, Sun Y, Musso F (2017) Assessment of bamboo application in building envelope by comparison with reference timber. Constr Build Mater 156:844–860. https://doi.org/10.1016/j.conbuildmat.2017.09.026

Richardson C, Mofidi A. Non-linear numerical modelling of sustainable advanced composite columns made from bamboo culms, pp 169–187, 202

Bansal AK, Zoolagud SS (2002) Bamboo composites: material of the future. 1(2):119–130

Chand N, Shukla M, Kumar M (2014) Analysis of mechanical behaviour of bamboo (Dendrocalamus strictus) by using FEM. Nov 2014, pp 37–41. https://doi.org/10.1080/15440470801928970

Li L (2012) Tensile properties of regenerated bamboo yarn. 1(90):20–22

Li Z, Zhang J, Xiao D, Xiao Y (2020) Estimation on tensile elastic properties of engineered bamboo boards with image information. In: The 2020 world congress on the 2020 structures congress (Structures 20), pp 25–28

Eskezia E, Abera A, Tilahun D (2017) Finite element analysis of internal door panel of a car by considering bamboo fibre reinforced epoxy composite. J Appl Mech Eng 6(1):1–6. https://doi.org/10.4172/2168-9873.1000247

Mat Kasim FA, Roslan SAH, Rasid ZA, Yakub F, Hassan MZ, Yahaya H (2021) Post-buckling of bamboo reinforced composite plates. IOP Conf Ser Mater Sci Eng 1051(1):012040. https://doi.org/10.1088/1757-899X/1051/1/012040

Askarinejad S, Kotowski P, Shalchy F, Rahbar N (2015) Effects of humidity on shear behavior of bamboo. Theor Appl Mech Lett 5(6):236–243. https://doi.org/10.1016/j.taml.2015.11.007

Sen T, Reddy HNJ (2011) A numerical study of strengthening of RCC beam using natural bamboo fibre. 3(5):707–713

Jena H (2017) Effect of cenosphere on thermal conductivity of bamboo fibre reinforced composites. Adv Mater Proc 2(2):97–102. https://doi.org/10.5185/amp.2017/207

Chandana E, Altaf Hussian D (2013) Thermal conductivity characterization of bamboo fibre reinforced in epoxy resin. IOSR J Mech Civ Eng 9(6):7–14

Alhijazi M, Zeeshan Q, Qin Z, Safaei B, Asmael M (2020) Finite element analysis of natural fibres composites: a review. Nanotechnol Rev 9(1):853–875. https://doi.org/10.1515/ntrev-2020-0069

Shinde SS, Salve AV, Kulkarni S (2017) Theoretical modeling of mechanical properties of woven jutefiber reinforced polyurethanecomposites. Mater Today Proc 4(2):1683–1690. https://doi.org/10.1016/j.matpr.2017.02.008

Rajkumar DR, Santhy K, Padmanaban KP (2021) Influence of mechanical properties on modal analysis of natural fiber reinforced laminated composite trapezoidal plates. J Nat Fibers 18(12):2139–2155. https://doi.org/10.1080/15440478.2020.1724230

José da Silva L, Hallak Panzera T, Luis Christoforo A, Miguel Pereira Dur L, Antonio Rocco Lahr F (2012) Numerical and experimental analyses of biocomposites reinforced with natural fibres. Int J Mater Eng 2(4):43–49. https://doi.org/10.5923/j.ijme.20120204.03

Joffre T, Miettinen A, Wernersson ELG, Isaksson P, Gamstedt EK (2014) Effects of defects on the tensile strength of short-fibre composite materials. Mech Mater 75:125–134. https://doi.org/10.1016/j.mechmat.2014.04.003

Eagala RY, Gopichand A, Raghavendra G, Ali S (2012) Abrasive wear behaviour of bamboo-glass fibre reinforced epoxy composites using Taguchi approach. Int J Adv Eng Technol 5(1):2231–1963

Prabhu R, Mendonca S, D’Souza R, Vas JP, Bhat T (2019) Application of Taguchi techniques to study the effect of alkaline treatment and fibre length on mechanical properties of short bamboo fibre reinforced epoxy composites. AIP Conf Proc 2080. https://doi.org/10.1063/1.5092902

Davoodi MM, Sapuan SM, Ahmad D, Aidy A, Khalina A, Jonoobi M (2011) Concept selection of car bumper beam with developed hybrid bio-composite material. Mater Des 32(10):4857–4865. https://doi.org/10.1016/j.matdes.2011.06.011

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Kumar, R., Mishra, S.K., Kumar, K. (2023). A Critical Review on Finite Element Models Towards Physico-Mechanical Properties of Bamboo Fibre/Filler-Reinforced Composite Materials. In: Palombini, F.L., Nogueira, F.M. (eds) Bamboo and Sustainable Construction. Environmental Footprints and Eco-design of Products and Processes. Springer, Singapore. https://doi.org/10.1007/978-981-99-0232-3_9

Download citation

DOI: https://doi.org/10.1007/978-981-99-0232-3_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-0231-6

Online ISBN: 978-981-99-0232-3

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)