Abstract

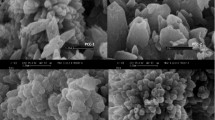

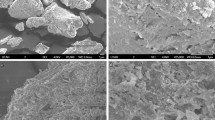

Carbide lime or lime sludge is a by-product of acetylene manufacturing through a hydrolysis of calcium carbide (CaCl2). In Malaysia, carbide lime is classified as a scheduled waste under Environmental Quality Act: EQA 1974 (SW 427). This industrial waste is frequently rich in calcium hydroxide (Ca(OH)2), rendering it a substitute potential precursor for producing marketable precipitated calcium carbonate (PCC). In addition to the abundant carbide lime waste, the acetylene production has also increased carbon dioxide (CO2) gas emission that traps heat in the atmosphere. This phenomenon has become a crucial environmental concern as the rise of CO2 gas emission leads to global warming. In order to overcome this environmental issue, the pair of carbide lime waste and CO2 gas were utilized as primary precursors in producing commercial-grade PCC. The precipitation process was achieved via feasible carbonation approach promoted using natural sucrose solution in extracting Ca2+ ions from the carbide lime waste. In investigating the effect of CO2 supply on the PCC formation, CO2 gas flow rate was varied i.e. 200, 400, 600, 800 and 1000 ml/min. Increasing the CO2 flow rate resulted in significant time reduction (from 33 min at 200 ml/min to only 9 min at 1000 ml/min) and particle refinement (from 5.28 µm at 200 ml/min to 1.16 µm at 1000 ml/min). Production of PCC with purity 96–98% suggested that the carbide lime waste was successfully transformed into marketable PCC, thus may help in preserving environmental sustainability.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Erdogan N, Eken HA (2017) Precipitated calcium carbonate production, synthesis and properties. Physicochemical Probl Mineral Process 53:57–68

Ana MLP, Roberta P, Carlos GG, Lourdes FV, Domingo C (2010) A breakthrough technique for the preparation of high-yield precipitated calcium carbonate. J Supercrit Fluids 52:298–305

Onimisi JA, Roniza I, Kamar SA, Norlia B, Hashim H (2016) A novel rapid mist spray technique for synthesis of single-phase precipitated calcium carbonate using solid-liquid-gas process. Korean J Chem Eng 34:1–5

Sun J, Wang L, Zhao D (2017) Polymorph and morphology of CaCO3 in relation to precipitation conditions in a bubbling system. Chin J Chem Eng 25:1335–1342

Walsh D, Mann S (1995) Fabrication of hollow porous shells of calcium carbonate from self organizing media. Nature 377:320–323

Santos RM, Pieter C, Tom VG (2012) Synthesis of pure aragonite by sonochemical mineral carbonation. Chem Eng Res Des 90:715–725

Ligia MMC, Gabriel MO, Rafael S (2017) Precipitated calcium carbonate nano-microparticles: applications in drug delivery. Adv Tissue Eng Regenerative Med 3:336–340

Salleh EM, Othman R, Mahim Z, Sabri SNM (2021) Effect of liquid feeding rate on carbonation of precipitated calcium carbonate via continuous method. J Phys Conf Ser 2080 (1):012017

Zevenhoven R, Legendre D, Said A, Jarvinen M (2019) Carbon dioxide dissolution and ammonia losses in bubble columns for precipitated calcium carbonate (PCC) production. Energy 175:1121–1129

Acknowledgements

This work was supported by the Ministry of Energy and Mineral Resources. The authors would like to thank Mineral Research Centre, Department of Mineral and Geoscience Malaysia and Rock Based Technology Section for the fund and technical supports.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Salleh, E.M., Othman, R., Sabri, S.N.M., Mahim, Z. (2023). Effect of Carbon Dioxide Gas Flow Rate on Production of PCC from Carbide Lime Waste. In: Maleque, M.A., Ahmad Azhar, A.Z., Sarifuddin, N., Syed Shaharuddin, S.I., Mohd Ali, A., Abdul Halim, N.F.H. (eds) Proceeding of 5th International Conference on Advances in Manufacturing and Materials Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-9509-5_11

Download citation

DOI: https://doi.org/10.1007/978-981-19-9509-5_11

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-9508-8

Online ISBN: 978-981-19-9509-5

eBook Packages: EngineeringEngineering (R0)