Abstract

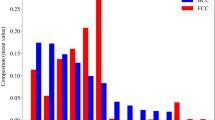

High-entropy alloys (HEAs) possess vast compositional space making them a suitable type of metallic alloy material that can be customized for a wide range of engineering applications ranging from structural, catalytic, functional, hydrogen storage and metamaterials. Predicting the phase of an HEA for a given composition in a certain molar ratio is a daunting task, and hitherto, trial-and-error approaches are employed. With the emergence of data-driven machine learning (ML) technique newer avenues have emerged to reduce the complexity in this task. In this work, we provide a canon of research in this area and used a testbed study by deploying random forest classifier (RFC) to predict distinct phases of HEAs, such as intermetallic (IM), BCC solid-solution (BCC_SS), FCC solid-solution (FCC_SS), and mixed (FCC + BCC) phase. With an average accuracy of 86%, a ROC_AUC score of 0.965, and tenfold cross-validation ROC_AUC score of 0.903, the random forest model showed great ability and prospects in future discovery of novel phases of HEAs. Based on this analysis, the input parameters such as the mixing enthalpy (ΔHmix) and valence electron concentration (VEC) were identified most influential in governing the stable phase of an HEA.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Katiyar N, Goel G, Goel S (2021) Emergence of machine learning in the development of high entropy alloy and their prospects in advanced engineering applications. Emergent Mater 4(6):1635–1648. https://doi.org/10.1007/s42247-021-00249-8

Senkova ON, Senkova SV, Woodward C, Miracle DB (2013) Low-density, refractory multi-principal element alloys of the Cr–Nb–Ti–V–Zr system: Microstructure and phase analysis. Acta Mater 61(5):1545–1557. https://doi.org/10.1016/j.actamat.2012.11.032

Stepanov N, Shaysultanov D, Salishchev G, Tikhonovsky M (2015) Structure and mechanical properties of a light-weight AlNbTiV high entropy alloy. Mater Lett 142:153–155. https://doi.org/10.1016/j.matlet.2014.11.162

Deng Y, Tasan C, Pradeep K, Springer H, Kostka A, Raabe D (2015) Design of a twinning-induced plasticity high entropy alloy. Acta Mater 94:124–133. https://doi.org/10.1016/j.actamat.2015.04.014

Zhang Y, Li R (2020) New advances in high-entropy alloys. Entropy 22(10):1158. https://doi.org/10.3390/e22101158

Tsai M, Yeh J (2014) High-entropy alloys: a critical review. Mater Res Lett 2(3):107–123. https://doi.org/10.1080/21663831.2014.912690

Youssef K, Zaddach A, Niu C, Irving D, Koch C (2014) A novel low-density, high-hardness, high-entropy alloy with close-packed single-phase nanocrystalline structures. Mater Res Lett 3(2):95–99. https://doi.org/10.1080/21663831.2014.985855

Cantor B (2021) Multicomponent high-entropy Cantor alloys. Prog Mater Sci 120:100754. https://doi.org/10.1016/j.pmatsci.2020.100754

Yeh J (2006) Recent progress in high-entropy alloys. Annales De Chimie Science Des Matériaux 31(6):633–648. https://doi.org/10.3166/acsm.31.633-648

Kremer K, Grest G (1990) Molecular dynamics (MD) simulations for polymers. J Phys Condens Matter 2(S):SA295-SA298. https://doi.org/10.1088/0953-8984/2/s/045

Neugebauer J, Hickel T (2013) Density functional theory in materials science. Wiley Interdiscip Rev: Comput Mol Sci 3(5):438–448. https://doi.org/10.1002/wcms.1125

Goel S, Knaggs M, Goel G, Zhou X, Upadhyaya H, Thakur V et al (2020) Horizons of modern molecular dynamics simulation in digitalized solid freeform fabrication with advanced materials. Mater Today Chem 18:100356. https://doi.org/10.1016/j.mtchem.2020.100356

Osisanwo FY, Akinsola JE, Awodele O, Hinmikaiye JO, Olakanmi O, Akinjobi J (2017) Supervised machine learning algorithms: classification and comparison. Int J Comput Trends Technol 48(3):128–138. https://doi.org/10.14445/22312803/ijctt-v48p126

Nasteski V (2017) An overview of the supervised machine learning methods. HORIZONS B 4:51–62. https://doi.org/10.20544/horizons.b.04.1.17.p05

Islam N, Huang W, Zhuang H (2018) Machine learning for phase selection in multi-principal element alloys. Comput Mater Sci 150:230–235. https://doi.org/10.1016/j.commatsci.2018.04.003

Huang W, Martin P, Zhuang H (2019) Machine-learning phase prediction of high-entropy alloys. Acta Mater 169:225–236. https://doi.org/10.1016/j.actamat.2019.03.012

Nassar A, Mullis A (2021) Rapid screening of high-entropy alloys using neural networks and constituent elements. Comput Mater Sci 199:110755. https://doi.org/10.1016/j.commatsci.2021.110755

Choudhury A, Konnur T, Chattopadhyay P, Pal S (2019) Structure prediction of multi-principal element alloys using ensemble learning. Eng Comput 37(3):1003–1022. https://doi.org/10.1108/ec-04-2019-0151

Risal S, Zhu W, Guillen P, Sun L (2021) Improving phase prediction accuracy for high entropy alloys with machine learning. Comput Mater Sci 192:110389. https://doi.org/10.1016/j.commatsci.2021.110389

Tancret F, Toda-Caraballo I, Menou E, Rivera Díaz-Del-Castillo P (2017) Designing high entropy alloys employing thermodynamics and Gaussian process statistical analysis. Mater Des 115:486–497. https://doi.org/10.1016/j.matdes.2016.11.049

Li Y, Guo W (2019) Machine-learning model for predicting phase formations of high-entropy alloys. Phys Rev Mater 3(9). https://doi.org/10.1103/physrevmaterials.3.095005

Qi J, Cheung A, Poon S (2019) High entropy alloys mined from binary phase diagrams. Sci Rep 9(1). https://doi.org/10.1038/s41598-019-50015-4

Zhou X, Zhu J, Wu Y, Yang X, Lookman T, Wu H (2022) Machine learning assisted design of FeCoNiCrMn high-entropy alloys with ultra-low hydrogen diffusion coefficients. Acta Mater 224:117535. https://doi.org/10.1016/j.actamat.2021.117535

Agrawal A, Choudhary A (2016) Perspective: materials informatics and big data: realization of the “fourth paradigm” of science in materials science. APL Mater 4(5):053208. https://doi.org/10.1063/1.4946894

Abdoon Al-Shibaany Z, Alkhafaji N, Al-Obaidi Y, Atiyah A (2020) Deep learning-based phase prediction of high-entropy alloys. IOP Conf Ser: Mater Sci Eng 987(1):012025. https://doi.org/10.1088/1757-899x/987/1/012025

Dai D, Xu T, Wei X, Ding G, Xu Y, Zhang J, Zhang H (2020) Using machine learning and feature engineering to characterize limited material datasets of high-entropy alloys. Comput Mater Sci 175:109618. https://doi.org/10.1016/j.commatsci.2020.109618

Kaufmann K, Vecchio K (2020) Searching for high entropy alloys: a machine learning approach. Acta Mater 198:178–222. https://doi.org/10.1016/j.actamat.2020.07.065

Zhang L, Chen H, Tao X, Cai H, Liu J, Ouyang Y et al (2020) Machine learning reveals the importance of the formation enthalpy and atom-size difference in forming phases of high entropy alloys. Mater Des 193:108835. https://doi.org/10.1016/j.matdes.2020.108835

Buranich V, Rogoz V, Postolnyi B, Pogrebnjak A (2020) Predicting the properties of the refractory high-entropy alloys for additive manufacturing based fabrication and mechatronic applications. In: IEEE international conference on “nanomaterials: applications & properties” (NAP-2020) symposium on additive manufacturing and applications (SAMA-2020) Sumy, Ukraine, 9–13 Nov 2020

Machaka R (2021) Machine learning-based prediction of phases in high-entropy alloys. Comput Mater Sci 188:110244. https://doi.org/10.1016/j.commatsci.2020.110244

Bhandari U, Rafi M, Zhang C, Yang S (2021) Yield strength prediction of high-entropy alloys using machine learning. Mater Today Commun 26:101871. https://doi.org/10.1016/j.mtcomm.2020.101871

Lee S, Byeon S, Kim H, Jin H, Lee S (2021) Deep learning-based phase prediction of high-entropy alloys: optimization, generation, and explanation. Mater Des 197, 109260. https://doi.org/10.1016/j.matdes.2020.109260

Zeng Y, Man M, Bai K, Zhang Y (2021) Revealing high-fidelity phase selection rules for high entropy alloys: a combined CALPHAD and machine learning study. Mater Des 202, 109532. https://doi.org/10.1016/j.matdes.2021.109532

Krishna Y, Jaiswal U, Rahul R (2021) Machine learning approach to predict new multiphase high entropy alloys. Scripta Mater 197:113804. https://doi.org/10.1016/j.scriptamat.2021.113804

Markoulidakis I, Rallis I, Georgoulas I, Kopsiaftis G, Doulamis A, Doulamis N (2021) Multiclass confusion matrix reduction method and its application on net promoter score classification problem. Technologies 9(4):81. https://doi.org/10.3390/technologies9040081

Lewis F, Butler A, Gilbert L (2010) A unified approach to model selection using the likelihood ratio test. Methods Ecol Evol 2(2):155–162. https://doi.org/10.1111/j.2041-210x.2010.00063

Acknowledgements

Swati Singh greatly acknowledge the scholarship provided by the Ministry of Education, Government of India. Saurav Goel greatly acknowledge the support provided by the Royal Academy of Engineering via Grants No. IAPP18-19\295 and TSP1332.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Singh, S., Joshi, S.N., Goel, S. (2023). Summary of Efforts in Phase Prediction of High Entropy Alloys Using Machine Learning. In: Joshi, S.N., Dixit, U.S., Mittal, R.K., Bag, S. (eds) Low Cost Manufacturing Technologies. NERC 2022. Springer, Singapore. https://doi.org/10.1007/978-981-19-8452-5_4

Download citation

DOI: https://doi.org/10.1007/978-981-19-8452-5_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-8451-8

Online ISBN: 978-981-19-8452-5

eBook Packages: EngineeringEngineering (R0)