Abstract

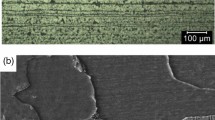

In the present study, Fe-based ER70S-6 filler rod of 1.2 mm diameter was cladded on a 6 mm AA 6061-T6 alloy sheet using a cold metal transfer process. The accelerated corrosion test was performed to evaluate the effect of corrosion on the hardness and wear resistance of the cladded surface. Acid corrosion resistance was studied by immersing the sample in 2.0% H2SO4 solution for 200 h. The morphology of the corroded surface was analyzed using upright optical and field emission scanning electron microscopes. Surface deterioration appears to be mostly caused by localized pitting corrosion. The weight loss due to corrosion was 8.9 × 10–4 g/mm2 after 200 h. The average microhardness reduced by 10% due to removal of hard materials and introduction of porosity on the cladded surface. The pin-on-disk test revealed significant reduction in wear resistance.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Fouad MA, Zewail TM, Amine NA, El-Tawail YA (2017) Comparison between corrosion behavior of copper and stainless steel 90° elbow and failure investigation of 90° copper elbow. J Inst Eng (India) Series C 98(2):141–145

Moorthy CV, Srinivas V (2016) Corrosion and heat transfer characteristics of water dispersed with carboxylate additives and multi-walled carbon nano tubes. J Inst Eng (India) Series C 97(4):569–577

Varghese P, Vetrivendan E, Dash MK, Ningshen S, Kamaraj M, Mudali UK (2019) Weld overlay coating of Inconel 617M on type 316 L stainless steel by cold metal transfer process. Surf Coat Technol 357:1004–1013

Tang X, Zhang S, Cui X, Zhang C, Liu Y, Zhang J (2020) Tribological and cavitation erosion behaviors of nickel-based and iron-based coatings deposited on AISI 304 stainless steel by cold metal transfer. J Mater Sci Technol 9:6665–6681

Selvi S, Vishvaksenan A, Rajasekar E (2018) Cold Metal Transfer (CMT) technology—an overview. Defence Technol 14(1):28–44

Rajeev GP, Kamaraj M, Bakshi RS (2017) Hardfacing of AISI H13 tool steel with stellite 21 alloy using cold metal transfer welding process. Surf Coat Technol 326:63–71

Das B, Panda BN, Dixit US (2022) Microstructure and mechanical properties of ER70S-6 alloy cladding on aluminum using a cold metal transfer process. J Mater Eng Perform. In press. https://doi.org/10.1007/s11665-022-06937-8

https://www.esabindia.com/in/en/products/filler-metals/mig-mag-wires-gmaw/mild-steel-wires/esab-mw1.cfm. Accessed on 5 May 2022

Kahyarian A, Schumaker A, Brown B, Nesic S (2017) Acidic corrosion of mild steel in the presence of acetic acid: mechanism and prediction. Electrochim Acta 258:639–652

https://www.suezwaterhandbook.com/water-and-generalities/corrosion-in-metal-and-concrete/protection-against-corrosion/cathodic-protection. Accessed on 2 May 2022

Hou X, Gao L, Cui Z, Yin J (2018) Corrosion and protection of metal in the seawater desalination. IOP Conf Series: Earth Environ Sci 108:022037

Panossian Z, Almeida NLD, Sousa RMFD, Pimenta GDS, Marques LBS (2012) Corrosion of carbon steel pipes and tanks by concentrated sulfuric acid: a review. Corros Sci 58:1–11

Jiru WG, Sankar MR, Dixit US (2019) Laser surface alloying of aluminum for improving acid corrosion resistance. J Inst Eng (India): Series C 100:481–492

Acknowledgements

The Central Instrumentation Facility of the Indian Institute of Guwahati (IITG) provided the testing facility. Cold Metal Transfer Welding Machine used in this work was procured by IITG Technology Innovation and Development Foundation (IITGTI&DF), which has been set up at IIT Guwahati as a part of the National Mission on Interdisciplinary Cyber Physical Systems (NMICPS). IITGTI&DF is undertaking research, development, and training activities on Technologies for Under Water Exploration with the financial assistance from Department of Science and Technology, India through grant number DST/NMICPS/TIH12/IITG/2020. Authors gratefully acknowledge all the support provided for conducting the present research.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Das, B., Panda, B.N., Dixit, U.S. (2023). Corrosion Behavior and Its Effect on Mechanical Properties of ER70S-6 Cladding on AA 6061-T6 Alloy Using a Cold Metal Transfer Process. In: Joshi, S.N., Dixit, U.S., Mittal, R.K., Bag, S. (eds) Low Cost Manufacturing Technologies. NERC 2022. Springer, Singapore. https://doi.org/10.1007/978-981-19-8452-5_2

Download citation

DOI: https://doi.org/10.1007/978-981-19-8452-5_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-8451-8

Online ISBN: 978-981-19-8452-5

eBook Packages: EngineeringEngineering (R0)