Abstract

Countries in sub-Saharan Africa (SSA) rely heavily on imported rice from Asia that is of superior quality compared to local rice. The objective of this study is to assess the impacts of the adoption of improved milling technologies and the associated structural transformation of the rice value chain from 2011 to 2019 using the original census of the rice millers in the Mwea Irrigation Scheme in Kenya. Our empirical analysis uses the doubly robust method and the endogenous switching model, which collectively reveal that the adopters of improved milling machines successfully improved the quality of locally milled rice. This allows it to compete with imported rice, thereby increasing the amount of domestic rice sold to supermarkets as well as urban traders and consumers. Through probit regression, it is also found that a few educated, entrepreneurial rice millers operating in rice milling clusters began using large-scale improved milling machines that included destoning capacity, importing them from China around 2010. Later, smaller improved machines were also introduced and these were more widely adopted into the rice milling clusters. In contrast, the many other millers that did not adopt improved machines were forced to downsize their business or exit the industry. These results suggest that adopting improved milling technologies—including destoners—is critical to improving the competitiveness of SSA’s domestic rice against imported rice.

This chapter draws heavily on Mano et al. (2022).

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

1 Introduction

Countries in sub-Saharan Africa (SSA) have made serious efforts to increase domestic staple food production to improve food security and reduce poverty, especially after the 2007–08 food crisis. Meanwhile, rice is an up-and-coming crop underpinning the increase in food production in SSA (Chap. 1 of this volume; Otsuka and Larson 2013, 2016; CARD 2019; Otsuka 2019). The annual growth rate of rice production was as high as 6.8% between 2009 and 2019 (Soullier et al. 2020; Chap. 2 of this volume). However, rice imports are estimated to be increasing more rapidly, at 7.8% per annum, and around one-third of the rice consumed in SSA is still imported from Asia in varying degrees ranging from 10 to 93% across the countries of the region (Mendez del Villar and Lançon 2015; Saito et al. 2015; FAO 2018).

Population growth, urbanization, and increasing incomes raise rice consumption. Urban consumers in coastal countries typically prefer imported Asian rice of superior quality relative to domestic rice (e.g., Mauritania, the northern part of Senegal, Liberia, Cote d’Ivoire, Ghana, Togo, Benin and Cameroon) (Diako et al. 2010; Demont 2013; Futakuchi et al. 2013; Demont et al. 2017; Ibrahim et al. 2020). By contrast, in landlocked countries or coastal countries that host a center of rice domestication, consumers traditionally prefer domestic rice (e.g., the southern Casamance region of Senegal, Guinea, Guinea-Bissau, Sierra Leone) (Britwum and Demont 2021; Demont 2013; Demont and Ndour 2015; Demont et al. 2017; Soullier et al. 2020). In Eastern Africa, Indian immigrants brought fragrant rice to Tanzania, which acted as a center of rice cultural heritage.Footnote 1 Nevertheless, massive rice imports may change consumer preference for imported rice, and it is crucial to improve the quality of African rice to strengthen its competitiveness. Among the many factors affecting grain quality, including varieties, cultivation, harvesting, threshing, and storage technologies (Futakuchi et al. 2013), the use of appropriate milling machines is critical if domestic milled rice is to compete with imported rice from Asia (Fiamohe et al. 2018; Ragasa et al. 2020). Research based on framed field experiments demonstrates that urban consumers are more willing to purchase rice with high cleanliness levels and low breakage rates of grains (Demont and Ndour 2015; Demont et al. 2017), indicating the importance of appropriate rice milling technology. Importantly, case studies by Tokida et al. (2014) and Kapalata and Sakurai (2020) reveal that adopting destoners and other improved milling machines also allows rice millers to charge higher milling fees and increases their profitability in Uganda and Tanzania.Footnote 2 However, the evidence remains limited on whether improved milling technologies enable domestic rice to compete with imported rice.

This paper analyzes the development of a rice milling cluster in Kenya’s most prominent rice production area, the Mwea irrigation scheme, situated 90 km northeast of Nairobi. This cluster has 8,500 hectares of irrigated paddy area, grows primarily improved Basmati riceFootnote 3 and has achieved a rice yield of 6.2 tons per hectare with two crop cycles (Chap. 10 of this volume; Njeru et al. 2016; Kikuchi et al. 2021). Until the early 2010s, millers and traders would hire casual workers to remove stones from the milled rice, which slowed the domestic rice supply to consumers. Some rice millers have gradually adopted improved milling machines over the past ten years, and the sale of Mwea rice in supermarkets began after the millers installed destoners. The rice milled by these millers is of higher quality and successfully competes with imported rice from Asia in urban markets, including in Nairobi, the capital of Kenya. On 11 December 2018, we observed supermarkets in Nairobi selling improved Basmati rice from Mwea at 140–200 Kshs per kg, compared with Pakistani long grain at 100–120 Kshs per kg.Footnote 4 Interviews with local experts suggest that high-quality rice, primarily consumed in the urban areas, comprises about 15–20% of total consumption. These observations indicate that African rice can compete with Asian rice if improved milling machines are introduced to the SSA (Chaps. 7 and 13 of this volume).

Data were collected from the commercial millers operating in Mwea in 2011, 2016, 2018, and 2019 to analyze the adoption process of destoners and other improved milling technologies and their effects on the quality of the milling service, their business performance, and survival rates in the market. Because destoners and other improved devices used to be mainly provided as part of large-scale multi-stage milling machines, only 3 out of the 82 millers sampled in 2011 and 15 out of 103 millers in 2016 were using destoners. Later, small- and medium-scale multi-stage milling machines with destoners became locally available, and 8 and 11 additional millers adopted destoners in 2018 and 2019, respectively. By contrast, many millers who did not adopt improved technologies were forced to shrink their businesses or exit the market. Using the doubly robust method and endogenous switching regression model to address the potential endogeneity of destoner adoption, we find that the adoption of improved rice milling technologies is associated with higher milling fees, a greater amount of milled rice being produced, and higher profitability. Moreover, the millers using destoners are more likely to survive in the market. These findings confirm the critical importance of improved rice milling technology in enhancing the quality of African rice.

The rest of this paper is organized as follows. Section 12.2 explains the data and describes the characteristics of sample rice millers in Mwea. Section 12.3 sets out the hypotheses tested in this study and explains the empirical strategy, and Sect. 12.4 describes the results. Section 12.5 discusses the results and draws policy implications.

2 Millers in Mwea

Figure 12.1 presents rice consumption, production, imports, and paddy price in Kenya from 2010 to 2019. After the 2007–2008 food crisis, the paddy price declined over time, consistent with the decline in the global price of rice (Chap. 10 of this volume; Kikuchi et al. 2021). While consumption and imports almost doubled, rice production was stagnant during this period in Kenya. A severe drought in 2016 and 2017 in the Horn of Africa region depressed rice production in the country over this period.

Rice consumption, production, imports, and paddy price in Kenya. Source Kenya National Bureau Statistics (2022)

The Mwea Irrigation Scheme produces 80–88% of the domestic rice in Kenya (Samejima et al. 2020). We studied the rice millers in Mwea to inquire into the development process of the rice milling sector and found that learning new technologies from overseas plays a crucial role in the development of rice milling. In what follows, we discuss the history of the development of the rice milling industry and explain our primary data collection in the context of Mwea.

2.1 Brief History

In the Mwea Irrigation Scheme, the history of modern rice milling dates back to 1967. A public rice miller, Mwea Rice Mill Ltd. (MRM), had monopoly rights over rice milling services and began operating four lines of a large multi-stage milling machine imported from Germany. In 1999 the rice sector was liberalized, and MRM started competing with other millers to provide milling services. In the early period of this process, the operators of multi-stage milling machines received on-the-job training at MRM, and some moved to other mills later.

In 2000, the Mwea Rice Growers Multipurpose Cooperative Society Ltd. (MRGM) purchased a large Chinese multi-stage milling machine without a destoner because they did not realize the importance of this function as they bought the machine from a broker in Nairobi without visiting China. In 2007, a private miller, Mwega, purchased a second-hand small-sized multi-stage milling machine with destoners. But this installation did not influence other millers, probably because Mwega’s mill was small at the time.

A significant event occurred in 2010 when the chairman and two workers of MRGM went to China to learn new milling technologies and purchase a new multi-stage milling machine. Notably, the new machine this time was equipped with a destoner, which improved the quality of milled rice by removing small stones and other impurities. In the following period, some owners of milling services who had expertise in rice marketing or had accumulated wealth through other business activities also started inquiring into new rice milling technologies by visiting machine suppliers in China. As a result, a little over ten private millers and the MRM installed large multi-stage milling machines in the first half of the 2010s. Aside from visiting China, these owners employed experienced operators, especially from MRM and MRGM.

Because small- or medium-sized multi-stage milling machines were introduced from China in the late 2010s to the local area, the importance of their destoner capability became widely recognized in rice milling clusters. Consequently, other millers, mainly those who were highly educated, also adopted destoners. By contrast, the remaining millers either reduced their business while using the traditional types of milling machines without destoners (so-called “Jets” and “fridges”) or exited the market.

2.2 Data

The authors visited the Mwea Irrigation Scheme in 2011, 2017, and 2020 to conduct a census of commercial rice millers. As with the other rice millers in SSA, the task of rice millers is primarily to provide a milling service for farmers and traders rather than purchasing paddy or selling milled rice to the market. Because December and January are the primary months for rice harvesting and milling in Mwea, our survey focused on rice millers’ characteristics and performance in January 2011, December 2016, December 2018, and December 2019.

We aimed to interview all the commercial rice millers in the region. However, there was no official list of rice millers during our survey in 2011 and 2017, so the coverage of the survey gradually expanded as we discovered additional millers operating in this area. In 2011, we visited the millers in Mwea town (locally known as Wanguru or Ngurubani), the primary rice milling cluster, stretching over 5 km along the Embu-Nairobi highway that connects Mwea with Nairobi in about 1.5 h. We then visited the millers in Mutithi, the secondary cluster located about 7 km south of Wanguru that extends about a kilometer along the highway. We also visited Kandongu town, which is about 4 km off the highway. In 2017, we maintained this strategy but also visited additional mills deemed commercial following a local rice extension officer’s advice. The 2020 survey is therefore the most comprehensive. We compared our list of rice millers with the list obtained from the Kirinyaga County government, which had also tried to construct a census of all rice millers in the county, and again found additional millers to contact.

2.3 Descriptive Statistics

Table 12.1 presents our sample millers’ basic characteristics by destoner adoption status, representing improved rice milling technologies, including pre-cleaners and graders (see Appendix Table 12.9), as of December 2019. The survey coverage expanded over the research period, and 62 and 45 millers were added in the 2017 and the 2019 surveys, respectively. The early adopters are those millers who adopted improved machines by 2016, and three did so in 2011. The adoption rate was low in 2011 but increased to nearly 15% in 2016. The late adopters are those millers that adopted destoners and other improved devices after 2016. Because of their adoption, the adoption rate increased to roughly 25% in 2018 and to 33% in 2019. At this time, almost all millers exiting the market were non-adopters.

The mid-point year of the establishment was 2009, with early and late adopters establishing themselves in 2005 and 2011 on average, respectively. Only one-quarter of non-adopters but most adopters of improved machines are located in the primary and secondary clusters, Mwea town and Mutithi, along the Embu-Nairobi highway. Although rice millers in the clusters are not tied by ethnicity or other social groups, they know each other very well and regularly exchange production and marketing knowledge. This frequent communication and information exchange facilitates the diffusion of new technology and marketing methods within each cluster. The average age of the main decision-makers was 50 years old, and they were mostly male. Only 45% of the non-adopters were high school graduates, whereas almost all the decision-makers among the adopters had completed high school education. As for their previous occupations, many decision-makers in the group of non-adopters were previously farmers, whereas the majority of the early and the late adopters had gained work experience in other businesses or formal jobs.

Table 12.2 presents the total milling capacity, the value of milling machines, and the number of employees. Almost all the respondent rice millers had only one milling machine.Footnote 5 In 2011, when only three early adopters used destoners, the average milling capacity was similar among the three groups of rice millers.Footnote 6 From 2011 to 2016, the average capacity of early adopters increased significantly. In 2019, the non-adopters continued to use the small traditional milling machines. While the early adopters had large-sized multi-stage milling machines, the late adopters installed small- or medium-sized multi-stage milling machines.Footnote 7

We also collected data on the total current market value of the milling machines assessed by the decision-makers in 2016, 2018, and 2019 (Table 12.2). The current market value of the early adopters’ milling machines was substantially higher than that of the late adopters’ milling machines, and the non-adopters’ traditional milling machines were the least valuable.Footnote 8 Furthermore, the non-adopters reduced their labor force over time, whereas the early adopters and the late adopters increased theirs as they installed milling machines with greater capacity (Table 12.2).

Table 12.3 presents the monthly milling performance of the sample millers for January 2011, December 2016, December 2018, and December 2019.Footnote 9 The average milling fees—which reflect the milling quality—of the early adopters and the late adopters were substantially higher than the milling fee of the non-adopters. Over time, the non-adopters’ milling fees increased between 2011 and 2016, after which they declined, likely reflecting decreased demand for their milling service. The early adopters’ milling fees increased substantially between 2011 and 2016 when all of them adopted destoners. Similarly, the late adopters’ milling fees increased between 2016 and 2019. We do not know why the late adopters’ milling fees were lower than that of non-adopters. It may well be that their strategy was to attract customers by reducing milling fees in the face of competition with the early adopters. As may be expected, in 2019, their average milling fee was slightly lower than that of the early adopters.

The amount of rice milled by non-adopters for customers declined between 2011 and 2019 (Table 12.3), whereas the early adopters’ milled rice increased during the same period. The late adopters’ amount of milled rice also increased substantially between 2016 and 2019, as they increased destoner adoption. Figure 12.2 documents the changes in the market share of the amount of milled rice by these three groups. In 2011, the non-adopter group dominated the milling service market with a market share of 80%, whereas the early adopter group rapidly increased its market share to 62% in 2016. The late adopters had a market share of 8% in 2011, but their market share has more than tripled in recent years. The non-adopters lost significant market share to the improved technology adopters and had only 7% of the market share by 2019. The near demise of non-adopters strongly indicates that milling machines with improved devices are profitable.

About 40% of sample rice millers purchased paddyFootnote 10 and sold milled rice to consumers and traders (Table 12.4). The proportion of millers that sold milled rice was similar across the three groups and did not change over time. The early adopters sold a substantially greater amount of milled rice than the late adopters. The amount of rice sold by the late adopters increased from 2016 to 2018 but remained small compared to the amount of rice milled for customers. These observations suggest that some early adopters shifted their business focus to selling rice, while the late adopters increased their share in the milling service. The non-adopters’ and the early adopters’ prices for sold rice declined between 2016 and 2019. The late adopters’ prices for sold rice substantially increased between 2016 and 2018 but fell in 2019, roughly comparable to the early adopters’ price.Footnote 11

Table 12.5 lists the paddy suppliers, the use of brand names in marketing, and the market channels of millers purchasing paddy and selling milled rice in December 2019 by destoner adoption. The non-adopters sourced paddy mainly from farmers, whereas the early and late adopters primarily purchased paddy from local traders. None of the non-adopters used brand names, but 50% of the early adopters and 25% of the late adopters used brand names. As for the marketing channels of millers who did not use brand names, the non-adopters sold milled rice to local consumers and traders. The early adopters and the late adopters without brand names sold milled rice to consumers and traders.Footnote 12 Notably, the adopters of brand names also sold milled rice directly to supermarkets, which require an ample supply of high-quality milled rice.

We calculated the monthly capacity utilization rate to examine milling productivity by dividing the actual amount of rice milled by the expected “full” amount of rice milled when all milling machines are operated for 200 h per month (Table 12.6).Footnote 13 The non-adopters reduced their capacity utilization rate over time between 2011 and 2019, showing decreased demand for the non-adopters’ milling service. The early adopters reduced their capacity utilization rate between 2011 and 2016 when they initially adopted large-scale multi-stage milling machines but they were unable to attract many customers for their milling service. However, the early adopters increased capacity utilization between 2016 and 2019, when they substantially increased their milling service, as observed in Table 12.3. The late adopters initially had a high capacity utilization rate in 2011, which dropped in 2016 but they maintained their capacity utilization rate in 2018 and slightly increased it in 2019, unlike the declining performance of the non-adopters. This monthly capacity utilization rate reflects the milling performance in the main season. We also calculated the annual capacity utilization rate in 2019 (Appendix Table 12.9). We found that the non-adopters had 0.13 and the late adopters had 0.30, a slightly reduced total but comparable to their performance in the main season. The early adopters, on the other hand, had 0.45, suggesting that the early adopters substantially reduced their milling performance in the offseason, leaving their large-scale milling machines idle.

The profit of the non-adopters was negative during the period between 2016 and 2019 (Table 12.6).Footnote 14 The early adopters’ profit was far the largest but declined substantially. By contrast, the late adopters’ profit increased between 2016 and 2019 as they upgraded their milling machines. Since the absolute amount of profit depends on the amount of investment, we also calculated the ratio of profit to milling capacity per month as an alternative indicator of the milling business’s profitability. The non-adopters had negative ratios between 2016 and 2019. The early adopters also had negative and declining ratios,Footnote 15 suggesting overcapacity for early adopters, particularly after the late adopters also adopted the improved milling machines. In contrast, although the late adopters initially had a negative ratio in 2016, they increased profit per capacity in 2018 and 2019.

3 Conceptual Framework and Empirical Strategy

3.1 Conceptual Framework

To understand Kenya’s current rice value chain transformations, it may be helpful to learn about Asia’s experience (Reardon et al. 2014), which can be summarized as follows: (1) medium and large rice mills upgrade milling equipment, which improves the quality of milled rice; (2) some of them introduce branding; (3) as a result, small mills are closed; and (4) vertical coordination takes place between farmers and medium and large mills, including contract farming, and between supermarkets/large urban retailers/wholesalers and medium and large mills. The descriptive analysis in the previous section suggests that processes (1)–(3) are taking place in Mwea, although we did not observe the existence of any contract farming.

Figure 12.3 summarizes the structural transformation of the rice value chain in Mwea. Traditionally, farmers and local traders bring paddy to rice millers who use traditional machines, primarily providing a milling service. Local traders and consumers purchase the rice milled by these traditional millers. By contrast, farmers sell paddy to local traders under the new system that brings paddy to rice millers adopting large-scale improved machines. Contract farming is not happening though, primarily because large-scale millers find it costly to trade with many small farmers directly.Footnote 16 Finally, some millers with improved machines have introduced brand names and sell milled rice to urban supermarkets directly. In the transition period, this type of rice miller also provides a simple milling service.

One of the key questions is who plays the role of the innovator that introduces new, improved machines. Most adopters of improved milling technologies operated in the rice milling clusters (Table 12.1). Advancing Marshall’s (1920) argument of agglomeration economies in industrial clusters, Sonobe and Otsuka (2006, 2011, 2014) provide a theory of cluster-based industrial development with ample supporting evidence from Asia and SSA. They argue that cluster-based industries typically expand through the entry of new firms imitating successful pioneers. However, the increasing supply of products without quality improvement reduces their prices, and hence, profitability—thereby inducing innovative firms to improve product quality to restore profitability. They also update marketing strategies to sell their new differentiated and improved products. Following these innovators, a small number of competent firms succeed in imitating such products and marketing innovations and expanding their businesses. In contrast, other firms fail to do so and eventually exit the market because of reduced profitability.

In the early 2010s, a few educated millers operating in the major rice milling clusters along the highway had learned the importance of the destoner component. The improved technologies were primarily available only with expensive large-sized multi-stage milling machines. Thus, the early adopters are likely to already understand the urban market and have sufficient wealth to make a significant initial investment. By the time small- and medium-sized multi-stage milling machines became available in the late 2010s, the importance of specialist knowledge about the marketing of high-quality rice and wealth had declined. However, the general human capital represented by education is expected to remain important in making the proper adoption decisions of milling machines. Moreover, because the millers operating in the rice milling clusters along the highway can attract more large urban traders keen on procuring high-quality milled rice,Footnote 17 they have a greater incentive to improve their milling quality. Based on these considerations, we hypothesize that:

Hypothesis 1: “Those educated millers who had acquired knowledge about the urban market or accumulated wealth through previous occupations or operations in rice milling clusters tended to adopt improved milling technologies early. Following the early adopters, other millers who were also highly educated and operating in the rice milling clusters adopted improved technologies later.”

As we learned in the previous section, because the only available improved milling machines in the early 2010s were large-sized, the early adopters could be expected to be large millers. They would have provided high-quality milling services and improved market performance in those years. In the late 2010s, small- and medium-sized multi-stage milling machines were introduced to Mwea. With the expanded milling capacity, the early and late adopters were more likely to purchase paddy from traders instead of farmers and sell milled rice directly to supermarkets as well as urban traders and consumers (Soullier et al. 2020). Based on these observations, we hypothesize that:

Hypothesis 2: “Both the early and the late adopters improved their product quality and expanded their business with improved milling technologies.”

During the 2010s, millers who adopted improved machines are expected to have improved their milling and overall business performance. In contrast, the remainder kept using traditional milling machines and performed poorly or exited the market because they lost the milling service business to the adopters. Thus, we also test the following hypothesis:

Hypothesis 3: “The non-adopters tend to exit the market because they lose milling service business to the adopters of improved machines, who were more likely to survive in the business.”

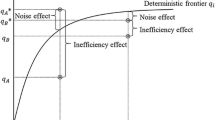

3.2 Doubly Robust and Endogenous Switching Regression

We consider an estimation strategy to explicitly control the selection of observables and match millers with similar characteristics. Earlier studies on agricultural technologies have used such estimation methods, including propensity score matching, inverse probability weighting, and the doubly robust (DR) method, when no other plausible instruments are available (Takahashi and Barrett 2014; Bellemare and Novak 2016; Kahn et al. 2019; Mano et al. 2020; Chap. 8 of this volume). We apply the DR method, or more precisely, an inverse probability weighted regression adjustment, that combines the regression and propensity score weighting. It is more robust than the propensity score matching estimator and the inverse probability weighting estimator. It can provide a consistent estimator as long as either the propensity score for destoner use or the outcome regression in terms of miller characteristics is correctly specified (Wooldridge 2007, 2010, Sect. 21.3.4).Footnote 18 More specifically, we first estimate the binary response model of improved technology adoption:

where \({D}_{it}^{*}\) is the latent variable of improved technology adoption, \({x}_{it}\) is the vector of miller i’s characteristics in a month of the main season in year t = 2011, 2016, 2018, 2019, \(\beta \) is the parameter to be estimated, \({\epsilon }_{it}\) is the error term, and the probability of improved technology adoption conditional on the miller’s characteristics can be expressed as the probit model:

where \(p\left({x}_{it}\right)\) is the propensity score of improved technology adoption. The miller’s characteristics are the decision-makers’ age, a high school dummy that takes the value of 1 if the decision-maker graduated from high school, the former occupation dummies, and the rice mill’s establishment year. Year dummies are also used. Using the estimated propensity \(\widehat{p}\left({x}_{it}\right)\), we estimate the regression parameters \(\gamma \)’s by using the following set of inverse probability weighting linear least-squares problems:

We estimate the average treatment effect on the treated (ATT) of the improved technology adoption on outcome \(Y\) as the average of the difference in predicted values of outcomes:

where \(\overline{{x }_{1}}={n}_{1}^{-1}\sum_{i}\sum_{t}{D}_{i}{x}_{it}\) is the vector of average characteristics of millers (including the constant term) over the improved technology adopters, and \({n}_{1}\) is the number of improved technology adopters. Here, \({\widehat{\tau }}_{ATT, DR}\) is the DR estimator of ATT. The outcome variables are the milling fee, the amount of rice milled for customers, the rice purchasing and selling dummy, which takes the value 1 if the miller purchased paddy and sold rice and 0 otherwise, the price of sold rice, the amount of sold rice, the capacity utilization rate, the gross profit, the gross profit per capacity, and the survival dummy, which takes the value 1 if the miller continued operation until the next period of our observation and 0 otherwise.

The other empirical strategy that we use is the endogenous switching regression (ESR). This method is also often used in the studies of agricultural technology adoption to address the endogeneity bias due to unobserved characteristics, which is assumed away by the DR method (Di Falco et al. 2011; Khonje et al. 2018; Bairagi et al. 2020). The first step is to estimate the binary response model of improved technology adoption (12.1), and the second step specifies the relationship between the outcome variable \({Y}_{it}\) and a vector of miller’s characteristics \({x}_{it}\) for improved technology adopters and non-adopters separately:

where subscripts 1 and 0 represent adopters and non-adopters, respectively, \(\delta \)’s are the vectors of regression coefficients, and \(\mu \)’s are the random error terms. The error terms in Eqs. (12.1), (12.3), and (12.4) are assumed to be jointly and normally distributed with mean vector zero and the following covariance matrix:

where \({\sigma }_{\epsilon }^{2}=var\left({\epsilon }_{it}\right)=1\), \({\sigma }_{1}^{2}=var\left({\mu }_{1it}\right)\), \({\sigma }_{0}^{2}=var\left({\mu }_{0it}\right)\), \({\sigma }_{\epsilon 1}=cov\left({\epsilon }_{it},{\mu }_{1it}\right)\), \({\sigma }_{\epsilon 0}=cov\left({\epsilon }_{it},{\mu }_{0it}\right)\), and the covariance between \({\mu }_{1it}\) and \({\mu }_{0it}\) are not defined because they are not observed simultaneously (Green 2012). The conditional expectation of the outcome of the destoner adopters in the actual case of adopting destoners can be expressed as:

where \(E\left({\mu }_{1it}|{D}_{it}=1, {x}_{1it}\right)={\sigma }_{\epsilon 1}\frac{\phi \left({x}_{1it}^{^{\prime}}\beta \right)}{\Phi \left({x}_{1it}^{^{\prime}}\beta \right)}\equiv {\sigma }_{\epsilon 1}{\lambda }_{1it}\). Analogously, the destoner adopters’ expected outcome in the counterfactual case of not adopting destoners can be expressed as:

Following Heckman et al. (2001) and Di Falco et al. (2011), we calculate the covariate-specific effect of the treatment on the treated as the difference between Eqs. (12.5) and (12.6):

Taking the average of this value over the destoner adopters, we obtain the ATT estimator of the destoner adoption using the endogenous switching regression:

where \(\overline{{x }_{1}}={n}_{1}^{-1}\sum_{i}\sum_{t}{D}_{i}{x}_{it}\) is the vector of average characteristics of millers (including the constant term) over the destoner adopters, \({\overline{\lambda }}_{1}\) is the average inverse mill’s ratio calculated using the regression parameter estimated in model (1), \(\delta \)’s and \(\sigma \)’s are parameters of regression (12.5) and (12.6) to be estimated.Footnote 19 Because we do not have a decent instrument for destoner adoption, we rely on the nonlinearity of the inverse mill’s ratio for identification in the parameter estimation (Wooldridge 2010). Analogously, we also estimate the average treatment effect on the untreated (ATUT), the hypothetical effect of adopting improved technologies for non-adopters:

where \(\overline{{x }_{0}}={n}_{0}^{-1}\sum_{i}\sum_{t}\left(1-{D}_{i}\right){x}_{it}\) is the vector of average characteristics of millers (including the constant term) over the non-adopters, \({\overline{\lambda }}_{0}\) is the average inverse mill’s ratio for non-adopters. We use ATUT estimates to examine whether non-adopters had lower expected profitability, which may explain why they did not adopt improved technologies.

4 Estimation Results

Table 12.7 presents the estimation results of the probit model of improved technology adoption of the early adopters with pooled data between 2011 and 2019 and of the late adopters between 2018 and 2019, when some or all of them had adopted improved machines. The decision-makers with a high school education or above and previous work experience in business and formal jobs tended to adopt large-scale improved milling technologies early. The main decision-makers of the late adopters were also found to have higher education but less previous work experience in rice marketing or mechanics. Both the early adopters and the late adopters were more likely to operate in the rice milling clusters. These results are consistent with Hypothesis 1.

Table 12.8 presents the estimation results of the DR method and the ESR method. We prefer the ESR method because it addresses potential selection on unobservables. Overall, however, the ATT estimates of improved technology adoption are similar between the two methods. We also estimated the ATT for early and late adopters separately using the DR method and the ATUT of improved technology adoption using the ESR method. The adoption of improved milling technologies increased milling fees for the adopters in general, the early adopters, and the late adopters. At the same time, it would have also increased the milling fees of the non-adopters if they had adopted the improved machines. These findings are consistent with Hypothesis 2. The improved technology adoption also increased rice milled for customers for the adopters in general, the early adopters, and the late adopters. At the same time, it would have also increased the amount of milled rice for the non-adopters.

The DR estimate of ATT of improved technology adoption on the probability of selling rice was significantly positive for the late adopters only. According to the corresponding ESR estimate, the improved technology adoption increased the probability of selling rice for the adopters in general. In contrast, it would have reduced the non-adopters’ probability of selling rice. We do not know why the adoption of improved milling machines would decrease the non-adopters’ likelihood of selling rice. We suspect that because the decision-makers of the non-adopters lack former work experience in business or general education (Table 12.1), they were incapable of increasing the profitability of selling rice simply by adopting improved machines. The adoption of improved machines increased the price of sold rice for the adopters in general and the late adopters, while it would have also increased the price of sold rice for the non-adopters. These findings are consistent with Hypothesis 2. The adoption of improved technologies increased the amount of sold rice for the adopters in general, the early adopters, and the late adopters. Moreover, it would have increased the rice sold for the non-adopters.

The adoption of improved machines increased the capacity utilization rate for the adopters in general, and it would have also increased it for the non-adopters. The DR estimates of the effect of improved machine adoption on profit were not statistically significant. However, according to the ESR estimates, improved technology adoption increased the profit for the adopters and would have reduced the profit for the non-adopters. As was explained earlier, because the decision-makers of the non-adopters lack work experience in business or general education, we suspect that they were incapable of increasing their profits simply by adopting improved machines. The estimated effect of improved machine adoption on the early adopters’ profit-capacity ratio was insignificant, whereas the adoption of improved machines significantly increased the late adopter’s profit-capacity ratio. According to the ESR estimates, improved technologies would have increased the profit-capacity ratio for the non-adopters.

We also estimated the ATT and ATUT of destoner adoption on the millers’ survival rates. Because we observed the late adopters’ technology adoption only during the last survey in 2020, we cannot analyze its effect on survival. The adoption of improved technologies increased the probability of early adopters’ survival, and it would have also increased the non-adopters’ survival probability. This result is consistent with Hypothesis 3.

5 Discussion

SSA heavily relies on imports from Asia to meet its rapidly increasing rice consumption due to population growth and urbanization, despite the efforts of various governments to improve food security by increasing rice farming productivity (Chap. 2 of this volume). Although consumers in some countries traditionally prefer domestic rice, massive rice imports have induced or may induce consumers to prefer imported rice. Thus, improving Africa’s milled rice quality is vital for competing with Asia’s milled rice (Chaps. 7 and13 of this volume). Mwea rice is of higher quality than imported Pakistani rice and, hence, is more expensive. This study explored why this is the case.

We found that learning improved milling technologies from abroad triggered the rice milling industry’s transformational improvement in Kenya’s largest rice production area, Mwea. After the 2007–2008 food crisis, a few educated and experienced decision-makers of rice milling companies located in the rice milling clusters visited China. They learned the importance of destoners and other improved rice milling machines in improving the quality of milled rice. They adopted large-scale multi-stage rice milling machines with destoners and other improved technologies in the first half of the 2010s. They successfully enhanced rice milling quality and sales of milled rice to urban supermarkets as well as consumers and traders. In the late 2010s, followers in the rice milling clusters introduced small- and medium-scale multi-stage rice milling machines to Mwea. Improved rice milling technologies were more widely adopted in the clusters, contributing to Mwea rice’s competitiveness against imported rice in the market. These findings strongly indicate the critical importance of adopting advanced technologies from abroad to improve enterprises’ performance in SSA.

5.1 Policy Implications

These findings suggest that the development process of the rice milling sector in Mwea is similar to Asia’s rice value chain transformations (as described by Reardon 2014) and may have significant implications for other SSA countries struggling to improve the quality of milled rice (Soullier et al. 2020; Chap. 13 of this volume). The critical point is that the adoption of destoners and other improved milling technologies has significantly improved the quality of local milled rice and its competitiveness against imported Asian rice. Moreover, we observed the associated transformation of rice value chains beyond the millers’ adoption of new technologies. The adopters of improved mills with greater milling capacity sourced paddy from local traders. Some adopters also branded their milled rice and developed a direct marketing channel to supermarkets as well as urban consumers and traders.

The previous National Rice Development Strategies (NRDS) of African countries under the Coalition for African Rice Development (CARD) initiative focused on increasing rice production (Demont 2013). However, in recognizing the importance of upgrading rice value chains to increase the quality-based competitiveness of domestic rice (Demont and Ndour 2015; Demont et al. 2017), African governments have added the installment of improved rice mills into the new set of NRDS. The current study provides supporting evidence that adopting destoners and other improved rice technologies increases the sales and price of domestic milled rice in urban markets.

We also observed that the introduction of small- and medium-scale multi-stage rice milling machines reduced the financial burden on potential adopters and assisted the widespread adoption of the new technology. In other words, the choice of appropriate technology is likely to be of crucial importance for SSA because the profitability of investment in improved machines varies and may not always be positive. To the extent that knowledge of various improved milling machines is a local public good, there is room for the government to provide appropriate information about the cost and benefit of various rice milling machines. Furthermore, we must note that, although the adoption of improved milling machines significantly improved the quality of rice and the performance of millers in Mwea, paddy produced in Mwea is a high-quality improved Basmati type that is uncommon in SSA. Whether the adoption of milling machines with destoners will enhance the quality of milled rice and millers’ performance in areas where more popular rice varieties are grown is a critical issue to be explored in future studies.

Notes

- 1.

Due to the influence of neighboring Tanzania, consumers in Kenya may also traditionally prefer domestic rice. But as we discuss below, supermarkets started selling domestic milled rice only after the millers adopted improved milling technologies.

- 2.

- 3.

Improved Basmati is a cross-breed between Basmati and high-yielding modern varieties and is widely grown in India and Pakistan. It is of lower quality but is higher yielding than original Basmati rice. A small amount of other rice varieties is produced solely for farmers’ domestic consumption.

- 4.

In 2019, Pakistan accounted for 67% of imported rice to Kenya, followed by Thailand with 25%, Republic of Korea with 3%, and India with 2% (KNBS 2021). The Pakistani rice is not Basmati but a type of long grain nonaromatic rice. According to our informal interviews with local rice traders, some sellers blend Mwea rice with imported rice from Pakistan and sell it as “Mwea rice.” However, note that consumers prefer high-quality Asian rice. For example, Jasmine rice from Thailand retailed at 350 Kshs per kg while Mwea rice was sold at 140–200 Kshs per kg.

- 5.

Only nine millers had two machines, and only one had three machines in 2019.

- 6.

Although we visited MRM and MRGM in 2011, we did not formally interview them because their technologies and business size seemed to be too distinct from other millers. We interviewed them in 2017 and 2019.

- 7.

The Appendix Table 12.9 shows that the areas of workshop, storage, and yard were also largest for the early adopters, followed by the late adopters, and the non-adopters had the smallest space. The early adopters attracted traders by offering their large storage space for free.

- 8.

We asked the decision-makers the total current market value of all the milling machines in the present state. In this paper, all the monetary values are deflated using the GDP deflator and presented in real 2019 values. The average exchange rate in December 2019 was 101.5 Kshs to 1 USD.

- 9.

Appendix Table presents the annual amount of rice sold in 2019. We believe the monthly data we use is more accurate than the annual data because of the shorter recall period.

- 10.

There is no contract farming system for rice, and these millers do not provide farmers with credit.

- 11.

Paddy quality is also crucial in determining overall rice quality, and farm-level agronomy affects the paddy quality, including leveling, fertilizer application, water usage during crop establishment, and pest and disease control. Mechanical harvesting has also helped reduce losses. Traders determine the paddy quality through observation and checking for moisture content. Many traders have moisture meters and usually check for the moisture content when purchasing. We do not observe a significant difference in the minimum required moisture content across the millers (Appendix Table 12.9). They also observe the paddy grain to ensure the pods are full, a sign of good quality paddy. But there is no grading system or pricing differential on paddy quality.

- 12.

According to local experts, these consumers and traders come from both local and urban areas.

- 13.

The monthly capacity utilization rate is the total amount of milled rice and sold rice (tons per month) divided by the milling capacity of machines for 200 h of operation (tons per month).

- 14.

We calculated profit by subtracting the labor costs, the purchasing cost of paddy, electricity costs, maintenance costs and the depreciation costs of milling machines from the revenue of milling service and selling rice and bran. The depreciation cost is estimated by assuming the linear depreciation over the usable lifetime, \(\mathrm{D}=\left(V-S\right)/\left(12\times L\right)\), where D = monthly depreciation, V = the value of machine, S = the salvage value of the machine after its useful life, assumed to be 10% of the machine value, L = useful life of the milling machine, assumed to be 10 years (Tokida and Barrett 2014; Norbu 2018). The estimation results are essentially robust to parameter values in reasonable ranges. Because of the data limitation, we did not consider other expenses such as the rental costs for the workspace and storage, marketing costs, or tax payments.

- 15.

The early adopters’ average profits are positive because of the large positive profits made by some millers using large milling machines despite the negative profits of other millers. But the average profit-capacity ratios reduced the weight of those successful large millers and turned out to be negative.

- 16.

Contract farming is designed to provide inputs on credit and production instruction (Otsuka et al. 2016). According to our previous study (Njeru et al. 2016), a credit market is working in Mwea. Furthermore, farmers understand production methods well due to the efficient extension system. Thus, the advantage of contract farming is nil. These observations may also explain the absence of vertical coordination between millers and farmers.

- 17.

Those rice millers can more easily source paddy rice because the clusters attract local traders and farmers.

- 18.

We used the STATA command teffects ipwra to implement the DR method.

- 19.

We used the STATA command movestay to implement the ESR method.

References

Arimoto Y, Sakane Y (2017) Japanese agriculture and rural issues (Nihon nougyo to nouson mondai). In: Fukao K, Nakamura N, Nakabayashi M (eds) Iwanami lecture series: history of Japanese economy (Iwanami-koza: Nihon keizai no rekishi). Iwanami Shoten Pub, Tokyo, pp 139–181

Bairagi S, Mishra AK, Durand-Morat A (2020) Climate risk management strategies and food security: evidence from Cambodian rice farmers. Food Secur 95:101935. https://doi.org/10.1016/j.foodpol.2020.101935

Bellemare M, Novak L (2016) Contract farming and food security. Am J Agric Econ 99(2):357–378. https://doi.org/10.1093/ajae/aaw053

Britwum K, Demont M (2021) Tailoring rice varieties to consumer preferences induced by cultural and colonial heritage: lessons from New Rice for Africa (NERICA) in The Gambia. Outlook Agric 50(3):305–314. https://doi.org/10.1177/0030727021101975

Coalition for African Rice Development (CARD) (2019) Rice for Africa. https://riceforafrica.net. Accessed 21 February 2021

Demont M (2013) Reversing urban bias in African rice markets: a review of 19 national rice development strategies. Glob Food Sec 2(3):172–181. https://doi.org/10.1016/j.gfs.2013.07.001

Demont M, Fiamohe R, Kinkpe AT (2017) Comparative advantage in demand and the development of rice value chains in West Africa. World Dev 96:578–590. https://doi.org/10.1016/j.worlddev.2017.04.004

Demont M, Ndour M (2015) Upgrading rice value chains: experimental evidence from 11 African markets. Glob Food Sec 5:70–76. https://doi.org/10.1016/j.gfs.2014.10.001

Di Falco S, Veronesi M, Yesuf M (2011) Does adaptation to climate change provide food security? A micro-perspective from Ethiopia. Am J Agric Econ 93(3):829–846. https://doi.org/10.1093/ajae/aar006

Diako C, Sakyi-Dawson E, Bediako-Amoa B, Saalia FK, Manful JT (2010) Consumer perceptions, knowledge, and preferences for aromatic rice types in Ghana. Nat Sci 8(12):12–19. http://197.255.68.203/handle/123456789/1233

Fiamohe R, Demont M, Saito K, Roy-Macauley H, Tollens E (2018) How can West African rice compete in urban markets? A Demand Perspective for Policymakers. Eurochoices 17(2):51–57. https://doi.org/10.1111/1746-692X.12177

Food Agricultural Organization (FAO) (2018) As rice import bills rise, African countries must sustain growth. http://www.fao.org/africa/news/detail-news/en/c/1154254/. Accessed 21 February 2021

Futakuchi K, Mnful J, Sakurai T (2013) Improving grain quality of locally produced rice in Africa. In: Wopereis MCS, Johnson D, Ahmadi N, Tollens E, Jalloh A (eds) Realizing Africa’s rice promise. Africa Rice Center, Benin, pp 311–323

Green WH (2012) Econometric analysis, 7th edn. Pearson Education Limited, New York

Heckman JJ, Tobias JL, Vytlacil EJ (2001) Four parameters of interest in the evaluation of social programs. South Econ J 68(2):210–223. https://doi.org/10.2307/1061591

Ibrahim LA, Sakurai T, Tachibana T (2020) Local rice market development in Ghana: experimental sales of standardized premium quality rice to retailers. J Agric Econ 22:118–122. https://doi.org/10.18480/jjae.22.0_118

Irukayama S (1939) Regarding rice inspection in Taiwan (Taiwan ni okeru beikoku kensani tsuite (Chuu-no-ni)). Taiwan Agricultural Association Bulletin (Taiwan noukaihou), 1–6 June 1939

Kapalata D, Sakurai T (2020) Adoption of quality-improving rice milling technologies and its impacts on millers’ performance in Morogoro region, Tanzania. J Agric Econ 22:101–105. https://doi.org/10.18480/jjae.22.0_101

Kenya National Bureau of Statistics (KNBS) (2022) Economic Survey 2021

Khan MF, Nakano Y, Kurosaki T (2019) Impact of contract farming on land productivity and income of maize and potato growers in Pakistan. Food Policy 85:28–39. https://doi.org/10.1016/j.foodpol.2019.04.004

Khonje MG, Manda J, Mkandwire P, Tufa AH, Alene AD (2018) Adoption and welfare impacts of multiple agricultural technologies: evidence from eastern Zambia. Agric Econ 49(5):599–609. https://doi.org/10.1111/agec.12445

Kikuchi M, Mano Y, Njagi TN, Merry D, Otsuka K (2021) Economic viability of large-scale irrigation construction in Sub-Saharan Africa: what if the Mwea irrigation scheme were constructed as a brand-new scheme? J Dev Stud 57(5):772–789. https://doi.org/10.1080/00220388.2020.1826443

KNBS (2021) Trade Map. https://www.trademap.org/. Accessed 11 July, 2021

Mano Y, Njagi TN, Otsuka K (2022) An inquiry into the process of upgrading rice milling services: the case of the Mwea Irrigation Scheme in Kenya. Food Policy 106:102195. https://doi.org/10.1016/j.foodpol.2021.102195

Mano Y, Takahashi K, Otsuka K (2020) Mechanization in land preparation and agricultural intensification: the case of rice farming in Cote d’Ivoire. Agric Econ 51(6):899–908. https://doi.org/10.1111/agec.12599

Marshall A (1920) Principles of Economics. Macmillan, London, UK

Mendez del Villar P, Lançon F (2015) West African rice development: beyond protectionism versus liberalization? Glob Food Secur 5:56–61. https://doi.org/10.1016/j.gfs.2014.11.001

Njeru TN, Mano Y, Otsuka K (2016) Role of access to credit in rice production in Sub-Saharan Africa: the case of Mwea irrigation scheme in Kenya. J Afr Econ 25(2):300–321. https://doi.org/10.1093/jae/ejv024

Norbu K (2018) Cost analysis of operating a medium-sized rice processing mill in Bhutan. Bhutanese J Agricul 1(1):70–76

Otsuka K (2019) Evidence-based strategy for a rice green revolution in sub-Saharan Africa. Japan International Cooperation Agency Research Institute Policy Note No. 5. JICA-RI, Tokyo

Otsuka K, Larson D (eds) (2013) An African green revolution: finding ways to boost productivity on small farms. Springer, Dordrecht, Netherlands

Otsuka K, Larson D (eds) (2016) In pursuit of an African Green Revolution: views from rice and maize farmers’ fields. Springer, Dordrecht, Netherlands

Otsuka K, Nakano Y, Takahashi K (2016) Contract farming in developed and developing countries. Ann Rev Resour Econ 8:353–376. https://doi.org/10.1146/annurev-resource-100815-095459

Ragasa C, Andam K, Asante S, Amewu S (2020) Can local products compete against imports in West Africa? Supply- and demand-side perspectives on chicken, rice, and tilapia in Accra Ghana. Glob Food Sec 26:100448. https://doi.org/10.1016/j.gfs.2020.100448

Reardon T, Chen KZ, Minten B, Adriano L, Dao TA, Wang J, Gupta SD (2014) The quiet revolution in Asia’s rice value chains. Ann N Y Acad Sci 1331:106–118. https://doi.org/10.1111/nyas.12391

Saito K, Dieng I, Toure AA, Somado EA, Wopereis MCS (2015) Rice yield growth analysis for 24 African countries over 1960–2012. Glob Food Sec 5:62–69. https://doi.org/10.1016/j.gfs.2014.10.006

Samejima H, Katsura K, Kikuta M, Njinju SM, Kimani JM, Yamauchi A, Makihara D (2020) Analysis of rice yield response to various cropping seasons to develop optimal cropping calendars in Mwea. Kenya. Plant Prod Sci 23(3):297–305. https://doi.org/10.1080/1343943X.2020.1727752

Sonobe T, Otsuka K (2006) Cluster-based industrial development: an East Asian model. Palgrave Macmillan, Hampshire, UK

Sonobe T, Otsuka K (2011) Cluster-based industrial development: a comparative study of Asia and Africa. Palgrave Macmillan, Hampshire, UK

Sonobe T, Otsuka K (2014) Cluster-based industrial development: Kaizen management for MSE growth in developing countries. Palgrave Macmillan, Hampshire, UK

Soullier G, Demont M, Arouna A, Lançon F, Mendez del Villar P (2020) The state of rice value chain upgrading in West Africa. Glob Food Sec 25:100365. https://doi.org/10.1016/j.gfs.2020.100365

Takahashi K, Barrett CB (2014) The system of rice intensification and its impacts on household income and child schooling: evidence from rural Indonesia. Am J Agric Econ 96:269–289. https://doi.org/10.1093/ajae/aat086

Tokida K, Haneishi Y, Tsuboi T, Asea G, Kikuchi M (2014) Evolution and prospects of the rice mill industry in Uganda. Afri J Agric Res 9(33):2560–2573. https://doi.org/10.5897/AJAR2014.8837

Wooldridge JM (2007) Inverse probability weighted estimation for general missing data problems. J Econom 141(2):1281–1301. https://doi.org/10.1016/j.jeconom.2007.02.002

Wooldridge JM (2010) Econometric analysis of cross section and panel data, 2nd edn. MIT Press, Cambridge MA

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Appendix

Appendix

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License (http://creativecommons.org/licenses/by-nc-nd/4.0/), which permits any noncommercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if you modified the licensed material. You do not have permission under this license to share adapted material derived from this chapter or parts of it.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 JICA Ogata Sadako Research Institute for Peace and Development

About this chapter

Cite this chapter

Mano, Y., Njagi, T.N., Otsuka, K. (2023). Rice Milling in Kenya: An Inquiry into the Process of Upgrading Rice Milling Services. In: Otsuka, K., Mano, Y., Takahashi, K. (eds) Rice Green Revolution in Sub-Saharan Africa. Natural Resource Management and Policy, vol 56. Springer, Singapore. https://doi.org/10.1007/978-981-19-8046-6_12

Download citation

DOI: https://doi.org/10.1007/978-981-19-8046-6_12

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-8045-9

Online ISBN: 978-981-19-8046-6

eBook Packages: Economics and FinanceEconomics and Finance (R0)