Abstract

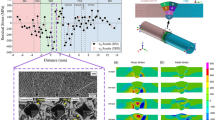

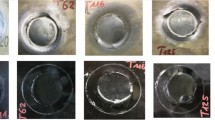

Thermo-mechanical treatments are essentially performed on wrought heat-treatable metallic alloys, before final application as structural materials. High homologous temperatures are maintained while plastically deforming the alloys, to eliminate defects induced while casting. Many of these alloys are also exposed to high temperature applications, encountering creep failure mechanism. Hence, high temperature deformation and creep behavior of different materials is an area of increased interest, using different methodologies. The present research aims to design and fabricate a laboratory-scale experimental setup, to substitute commercial hi-end equipment, for high temperature impression creep testing. Heating arrangement for desired temperatures and provision for variable load application have been combined into one single desktop unit. Impression creep indentation on a material can be estimated, for various combinations of loads and temperatures, generating creep curves, homologous to conventional tensile creep tests. The functionality and compatibility of the setup were successfully validated by conducting impression creep experiments on 2219Al alloys, under varying conditions of loads and temperatures. The generated creep curves with three distinct creep stages, as well as creep rates, were analyzed with respect to time, and compared with the theoretical models. The individual influences of load and temperature on creep properties of the alloy were investigated. Different creep parameters of minimum creep rate, penetration depth, penetration velocity, stress exponent, and activation energy were further evaluated and successfully compared and correlated with the reported literatures.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Callister WD (1997) Material science and engineering: an introduction. 4th edn. John Wiley & Sons

Mishra RS, Mukherjee AK (1995) Lightweight aluminum alloys for aerospace applications III. TMS Warrendale, Pennsylvania, pp 319–332

Dieter GE (1988) Engineering materials: mechanical metallurgy. In: 4th edn. John Wiley & Sons

Matsunaga T, Sato E (2013) Creep mechanism in several grades of aluminum at low temperatures. Mater Trans-Jpn Inst Light Met 54(12):2202–2208

Rashid AB, Khan MA, Kader MF (2019) Performance evaluation of a low cost creep testing machine. Am J Mech Eng 7(1):41–44

Deshmukh SP, Mishra RS, Kendig KL (2004) Creep behavior and threshold stress of an extruded Al–6Mg–2Sc–1Zr alloy. Mater Sci Eng 381:381–385

Blum W (1991) Creep of aluminium and aluminium alloys. Institut Fuel 5, D 8520 ErIangen, Germany

Dandrea JC, Lakes R (2009) Creep and creep recovery of cast aluminium alloys. Mech Time-Depend Mater 13:303–315

Thenambika V, Jayalakshmia S, Singh RA, Nidhia JK, Gupta M (2016) Impression creep behaviour of extruded Mg-Sn Alloy. Int J Veh Struct Syst 8(3):174–178

Wang SH (1994) Impression creep behavior in weldments. J Mar Sci Technol 2(1):17–24

Naveena, Vijayanand VD, Ganeshan V, Laha K, Mathew MD (2013) Application of impression creep technique for development of creep resistant Austenitic stainless steel. In: 6th International conference on creep, fatigue and creep-fatigue interaction 2013, [CF-6] vol 55, pp 585–590

Brett SJ, Kuhn B, Rantala J, Hyde CJ (2014) Impression creep testing for material characterization in development and application. Master’s thesis, Dept. Mechanical, Materials & Manufacturing Engineering, University of Nottingham

Asif S, Auradi V, Nagaral M, Kodanda C (2018) A review on fatigue and creep, behavior of aluminium composites. J Eng Res Appl 8(10):2248–9622

Yang F, Li JCM (2013) Impression test-a review. Mater Sci Eng R 74(8):233–253

Kumar A (2018) A study of impression creep behavior of friction stir welded Al-5052 and Al-2014 Alloys. In: Technical report, department of mechanical engineering, Indian Institute of Technology, Guwahati, India

Dehnavi M, Vafaeenezhad H, Khakzadi M, Nayebpashaee N, Eivani AR (2016) Modelling and prediction impression creep behavior of Al-Cu cast. Int J Cast Met Res 30

Ramesh R, Muthukannan D, Vijay P, Shweta V, Rajendran R (2015) Microstructural and mechanical characterization of Ti6Al4V refurbished parts obtained by laser metal deposition. Mater Sci Eng, A 643:64–71

Ramesh R, Vinothkumar S, Jie S, Manikandan N, Yanzhe Z (2019) Experimental and Taguchi-based grey approach of laser metal deposition technique on nickel-based superalloy. Trans Indian Inst Met 72(1):205–214

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Gogoi, S., Boruah, R., Ahmed, M., Banerjee, S., Kirtania, S., Kashyap, S. (2023). Design and Fabrication of Impression Creep Testing Setup and Experimental Validation with 2219Al Alloys. In: Arockiarajan, A., Duraiselvam, M., Raju, R., Reddy, N.S., Satyanarayana, K. (eds) Recent Advances in Materials Processing and Characterization. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-5347-7_8

Download citation

DOI: https://doi.org/10.1007/978-981-19-5347-7_8

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-5346-0

Online ISBN: 978-981-19-5347-7

eBook Packages: EngineeringEngineering (R0)