Abstract

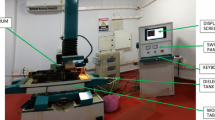

Wire-cut electrical discharge machine (W-EDM) is a precision machining approach that produces geometrically complex structures with a high level of accuracy and a smooth surface finish. The W-EDM is an unconventional machining technique which is also characterized by longer machining times which affect the machining characteristics. As it is modified process, still research is going on to find out optimum settings of pulse parameters which will improve the machining rates. HCHCR (High Carbon High Chromium) contains the minimum of 1.5–2.35% carbon and 12% of chromium widely used in thread rolling dies, hobs, and extrusion tools and therefore chosen as work piece material. In this present work, the HCHCR is taken as work piece, 0.25 mm diameter of brass wire used as the tool. For the experimentation, L-16 orthogonal array (OA) has been applied. The I/P process parameters chosen for optimizations are pulse on time (Ton), pulse off time (Toff), Servo Voltage (SV), Wire Feed (WF), Material Removal Rate (MRR), Surface Roughness (SR), and Kerf width (KW) as the performance characteristics. In the present study, Grey Relational Analysis (GRA) and Taguchi optimization method and ANOVA are used to analyze the results. The present work focuses on to develop and simulate an optimization model using Taguchi, GRA, and ANOVA for attaining higher MRR, lower SR, and KW. Hence, this work deals with the multi-objective optimization of process parameters in W-EDM with HCHCR as work material.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Durairaj M, Sudharsun D, Swamynathan N (2013) Analysis of process parameters in wire EDM with stainless steel using single objective Taguchi method and multi objective grey relational grade. Proc Eng 64:868–877

Kumar A, Singh DK (2012) Performance analysis of wire electric discharge machining (W-EDM). Int J Eng Res Technol (IJERT) 1(4):1–9

Kumar S, Kumar P (2016) Investigation of material removal rate for wire-cut EDM of EN-31 alloy steel using Taguchi technique. Int J Sci Eng Res 7(12):155–161

Lal S, Sudhir Kumar ZA, Siddiquee AN (2013) Research and developments in wire electrical discharge machining (WEDM): a state of art

Singh P et al (2015) Experimental investigation of wire EDM to optimize dimensional deviation of EN8 steel through Taguchi’s technique. Int Res J Eng Technol (IRJET) 2(3):1753–1757

Karabulut Ş et al (2018) Study on the wire electrical discharge machining of AA 7075 aluminum alloy. In: 2018 9th international conference on mechanical and aerospace engineering (ICMAE). IEEE

Mukhuti A, Rout A, Tripathy S (2016) Optimization of INCONEL 600 using wire EDM by MOORA and Taguchi’s method. In: 2016 international conference on electrical, electronics, and optimization techniques (ICEEOT). IEEE

Raju R, Sivalingam V, Sun J, Natarajan M, Zhao Y (2019) Experimental and Taguchi-based grey approach of laser metal deposition technique on nickel-based superalloy. Trans Indian Inst Met 72(1):205–214

Raju R, Manikandan N, Palanisamy D, Arulkirubakaran D, Sampath Kumar S, Bhanu Prakash P (2018) Optimization of process parameters in electrical discharge machining of haste alloy C276 using Taguchi’s method. Mater Today Proc 5(6):14432–14439

Rao PS, Ramji K, Satyanarayana B (2014) Experimental investigation and optimization of wire EDM parameters for surface roughness, MRR and white layer in machining of aluminium alloy. Proc Mater Sci 5:2197–2206

Manikandan N, Raju R, Palanisamy D, Arulkirubakaran D, Sampath Kumar S (2018) Investigation on Ti6Al4V laser metal deposition using Taguchi based grey approach. Mater Today Proc 5(6):14375–14383

Mandal K et al (2019) Analysis of wire-EDM input parameters on kerf width and surface integrity for Al 6061 alloy. In: Innovation in materials science and engineering. Springer, Singapore, pp 35–41

Palanisamy D, Manikandan N, Raju R, Arul Kirubakaran D, Binoj JS (2020) Prediction of performance measures in wire electrical discharge machining of aluminum–fly ash composites using regression analysis. In: Advances in industrial automation and smart manufacturing. Lecture notes in mechanical engineering. Springer, pp 387–396

Dastagiri M, Srinivasa Rao P, Madar Valli P (2016) TOPSIS, GRA methods for parametric optimization on wire electrical discharge machining (WEDM) process. In: Design and research conference (AIMTDR–2016) College of Engineering-India

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sathish Kumar, M., Satyanarayana, B. (2023). Optimization of Process Parameters in W-EDM with HCHCR by Using Taguchi Optimization Technique and Grey Relational Analysis. In: Arockiarajan, A., Duraiselvam, M., Raju, R., Reddy, N.S., Satyanarayana, K. (eds) Recent Advances in Materials Processing and Characterization. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-5347-7_5

Download citation

DOI: https://doi.org/10.1007/978-981-19-5347-7_5

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-5346-0

Online ISBN: 978-981-19-5347-7

eBook Packages: EngineeringEngineering (R0)