Abstract

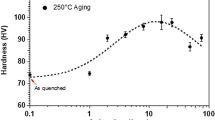

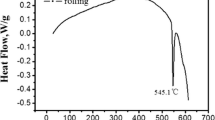

The 2219Al alloy system microalloyed with varying contents (0–0.1 wt%) of Sn and Cd was separately processed through casting route. Overall age-hardening behaviour of cast and solutionized alloy with trace contents of Sn and Cd was individually studied, by generating the age-hardening curves at given precipitation temperature of 170 °C. Independent influences of elemental Sn and Cd on the peak-hardness, peak-ageing time, and thermal stability were investigated. For all investigated alloys, hardness increased with ageing time up to peak-hardness corresponding to peak-ageing time. Hardness dropped during over-ageing. Peak-ageing times of 2219Al alloy were evaluated to be 24 h and 40 h, when microalloyed, respectively, with Sn and Cd. The peak-hardness was achieved more steadily and faster, when microalloyed with Sn, indicating an accelerated precipitation kinetics. Trace contents of either Sn or Cd had no appreciable effect on peak-ageing time. But, trace additions of both Sn and Cd can potentially induce a higher thermal stability on the strengthening effect at elevated temperatures. For a constant peak-ageing time, the peak-hardness increased with adding either Sn or Cd up to 0.06 wt%, while further contents of the microalloying elements decreased the peak-hardness. Peak-ageing conditions to achieve best possible hardness or mechanical strength could be optimized for 2219Al alloys microalloyed with Sn and Cd. The influences of the individual microalloying elements Sn and Cd on the peak-ageing characteristics of the alloy were compared and correlated with available literature.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Rana RS, Purohit R, Das S (2012) Reviews on the influences of alloying elements on the microstructure and mechanical properties of aluminium alloys and aluminium alloy Composites. Int J Sci Res Publ 2(6):2250–3153

Wilm A (1906) German patent. Patent no: DRP244554

Rao KS (2010) Microstructure of age hardenable AA2219 aluminium alloy modified by Sc, Mg and Zr additions. Trans Indian Inst Met 63(2):379–384

Kaibyshev R, Kazakulov I, Gromov D, Muskin F, Lesuer DR, Neih TG (2001) Superplasticity in 2219 Al-alloys. Scr Matterilla 44:2411–2417

Sercombe TB, Schaffer GB (1999) On the use of trace additions of Sn to enhance sintered 2xxx series Al powder alloys. Mater Sci Eng A 268:32–39

Murayama M, Hono K (2001) Role of Ag and Mg on precipitation of T1 phase in an Al–Cu–Li–Mg–Ag alloy. Scr Materilla 44(4):701–706

Miao WF, Laughlin DE (2000) Effects of Cu content and presaging on precipitation characteristics in aluminium alloy 6022. Metall Mater Trans A 31(A):361–371

Chakrabarti DJ, Cheong BK, Laughlin DE (1998) Precipitation strengthening of aluminium alloys AA6111. In: Automotive alloys II, pp 27–44

Mitlin D, Radmilovic V, Dahmen U, Morris JW (2003) On the influence of Si–Ge additions on the aging response of Al–Cu alloys. Metall Mater Trans A 32(A):735–742

Maksimovic V, Slavicazec V, Radmilovic M, Jovanovic T (2003) The effect of microalloying with silicon and germanium on microstructure and hardness of a commercial aluminium alloy. J Serb Chem Soc 68(11):893–901

Gogoi S (2017) Effect of rolling and age-hardening on the mechanical properties of microalloyed 2219 Al alloy. MTech Thesis, Department of Mechanical Engineering, Tezpur University

Banerjee S (2011) Mechanical properties and high temperature deformation behaviour of Al–Cu–Mg alloys microalloyed with tin. Doctoral Thesis, IIT Guwahati, Assam, pp 1–176

Banerjee S, Robi PS, Srinivasan A (2010) Calorimetric study of precipitation kinetics of Al–Cu–Mg and Al–Cu–Mg-0.06 wt% Sn alloys. Metals Mater Int 16(4):523–531

Banerjee S, Robi PS, Srinivasan A (2012) Prediction of hot deformation behaviour of Al-5.9%Cu-0.5%Mg alloys with trace additions of Sn. J Mater Sci 47(2):929–948

Banerjee S, Robi PS, Srinivasan A (2012) Deformation processing maps for control of microstructure in Al–Cu–Mg alloys microalloyed with Sn. Metall Mater Trans A 43:3834–3849

Banerjee S, Bhadra R, Gogoi S, Dutta RS (2020) Investigating weldability in microalloyed Al alloys. In: Advances in mechanical engineering, p 271

Banerjee S, Gogoi S (2016) Influence of trace addition of Cd on the hardness and impact properties of 2219 Al alloy. J Appl Eng Res 13(3):1202

Jeyaprakash N, Duraiselvam M, Raju R (2018) Modelling of Cr3C2–25% NiCr laser alloyed cast iron in high temperature sliding wear condition using response surface methodology. Arch Metall Mater 63(3):1303–1315

Raju R, Manikandan N, Palanisamy D, Arulkirubakaran D, Sampath Kumar S, Bhanu Prakash P (2018) Optimization of process parameters in electrical discharge machining of haste alloy C276 using Taguchi’s method. Mater Today Proc 5(6):14432–14439

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Banerjee, S., Gogoi, S. (2023). Optimizing the Peak-Ageing Conditions for Microalloyed 2219Al Alloys. In: Arockiarajan, A., Duraiselvam, M., Raju, R., Reddy, N.S., Satyanarayana, K. (eds) Recent Advances in Materials Processing and Characterization. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-5347-7_4

Download citation

DOI: https://doi.org/10.1007/978-981-19-5347-7_4

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-5346-0

Online ISBN: 978-981-19-5347-7

eBook Packages: EngineeringEngineering (R0)