Abstract

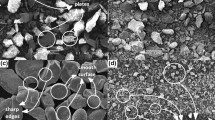

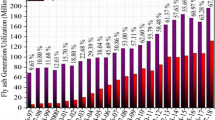

One of the major pollutants from thermal power plants is fly ash, which is a by-product of the combustion of pulverized coal. Fly ash consists of oxides of metals (primarily aluminum, silicon that constitute refractory compounds) heavy metals, sulfur, potassium, and sodium. It is generally dumped in the landfills, and hence, its leaching effect severely pollutes the environment. Hence, effective utilization of fly ash is the need of the hour. Also, the use of refractories is rapidly increasing in various applications because of their excellent properties and low-cost economic production. This work is on the development of technology to fabricate fly ash-based refractory bricks using 100% fly ash. The fabricated fly ash-based refractory bricks are characterized for their physical and mechanical properties. Also, the surface morphology, elemental composition, and phase composition are analyzed. The results demonstrate that the fabricated fly ash-based refractory bricks have desired physio-mechanical properties such as density of 1.7 cm3, compression strength of 10 MPa, and less than 1% water absorption.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Change history

13 September 2023

A correction has been published.

References

Jagadeep R et al (2021) Mater Today Proc

Alex AJ et al (2020) Aust J Mech Eng 1

Govindaraju M et al (2020) Proc Inst Mech Eng Part C J Mech Eng Sci 234(12):2474

Guha Keshav M et al (2021) Mater Today: Proc 46:4493

Kannan KR et al (2019) Tribological performance of heavy-duty functionally gradient friction material (Cu–Sn–Fe–Cg–SiC–Al2O3) synthesized by PM route. In: Presented at International conference on materials, manufacturing and machining

Rajesh Kannan K et al (2020) Proc Inst Mech Eng Part J: J Eng Tribol 235(7):1463

Kusiorowski R (2020) Constr Build Mater 231

Liu X et al (2021) Ceram Int 47(6):8685

Shimizu T et al (2013) J Eur Ceram Soc 33(15–16):3429

Otero JG et al (2013) Br Ceram Trans 103(4):181

Kishor MSVR et al (2020) J Mater Eng Perform 29(10):6307

Chakraborty AK et al (2013) Adv Appl Ceram 106(4):196

Wang T et al (2020) Constr Build Mater 239

Baradaran-Nasiri A, Nematzadeh M (2017) Constr Build Mater 147:865

Zhang J et al (2007) J Hazard Mater 149(2):523

Ewais EMM et al (2017) Refract Ind Ceram 58(2):136

Abbas S et al (2017) J Build Eng 14:7

Standard test method for cold crushing strength (2015). https://doi.org/10.1520/c0133-97r15

Standard test methods for Refractory brick (2010). https://doi.org/10.1520/c0020-00r10

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Balasubramanian, K., Vaira Vignesh, R., Periyaswamy, K., Govindaraju, M. (2023). Fabrication of Fly Ash-Based Refractory Brick Through Powder Metallurgy Technique. In: Revankar, S., Muduli, K., Sahu, D. (eds) Recent Advances in Thermofluids and Manufacturing Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-4388-1_44

Download citation

DOI: https://doi.org/10.1007/978-981-19-4388-1_44

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-4387-4

Online ISBN: 978-981-19-4388-1

eBook Packages: EngineeringEngineering (R0)