Abstract

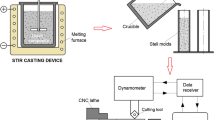

Drilling characteristics in combination with machining factors such as thrust force, torque, and burr height, when drilling on Al7029+B4C and Al7029+B4C-Gr composites are conducted. The liquid metallurgical technique used in the production of composites. The results revealed that considerable influence on thrust force and the exit burr height was caused by the feed rate. The Al7029/10% B4C-5% Gr hybrid composite displays reduced thrust force and burr height, while the Al7029/10% B4C composite has the opposite effect. Graphite surface lubricating characteristics led to the decreased thrust force, torque, and burr height. Graphene-derived chips are discontinuous, allowing them to have applications that involve discontinuous chips. It has been observed that carbide tools are advantageous over the TiN-coated HSS drill bit for machining HMMCs.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ozben T, Kilickap E, Cakır O (2008) Investigation of mechanical and machinability properties of SiC particle reinforced Al-MMC. Mater Proc Tech 198(1–3):220–225

Basavarajappa S, Chandramohan G, Davim JP, Prabu M, Mukund K, Ashwin M, Prasanna Kumar M (2008) Drilling of hybrid aluminium matrix composites. Adv Manuf Technol 35(11–12):1244–1250

Sharath BN, Jeevan TP, Baig MA, Ashrith HS, Afzal A, Reddy AR (2021) Machinability studies on boron carbide and graphite reinforced aluminium hybrid composites. Mater Today Proc 46:8734–8741

Sharath BN, Venkatesh CV, Afzal A, Aslfattahi N, Aabid A, Baig M, Saleh B (2021) Multi ceramic particles inclusion in the aluminium matrix and wear characterization through experimental and response surface-artificial neural networks. Materials 14(11):2895

Basavarajappa S, Chandramohan G, Prabu M, Mukund K, Ashwin M (2007) Drilling of hybrid metal matrix composites—workpiece surface integrity. Mach Tools Manuf 47(1):92–96

Rajmohan T, Palanikumar K, Kathirvel M (2012) Optimization of machining parameters in drilling hybrid aluminium metal matrix composites. Trans Nonfer Met Soc China 22(6):1286–1297

Rana RS, Purohit R, Das S (2012) Review of recent studies in Al matrix composites. Sci Eng Res 3(6):1–16

Chaudhary G, Kumar M, Verma S, Srivastav A (2014) Optimization of drilling parameters of hybrid metal matrix composites using response surface methodology. Procedia Mater Sci 6:229–237

Ramulu M, Rao PN, Kao H (2002) Drilling of (Al2O3)p/6061 metal matrix composites. Mater Proc Tech 124(1–2):244–254

Sathia Prathap VSK, Vengatachalapathy K, Planiradja (2014) Machining of hybrid metal matrix composites and its further improvement-a review. Eng Adv Tech 4(1): 11–15

Madhu KS, Venkatesh CV, Sharath BN, Karthik S (2021) Effect of Boron Carbide on wear resistance of graphite containing Al7029 based hybrid composites and its dry sliding wear characterization through experimental, response surface method and ANOVA. Trib Finn Trib 38(3–4):48–60

Sharath BN, Venkatesh CV (2021) Study on effect of boron carbide, aluminium oxide and graphite on dry sliding wear behaviour of aluminium based metal matrix composite at different temperature. Trib Finn Trib 38(1–2):35–46

Sharath BN, Madhu KS, Venkatesh CV (2019) Experimental study on dry sliding wear behaviour of Al-B4C-Gr metal matrix composite at different temperatures. Appl Mech Mater 895:96–101

Sharath BN, Venkatesh CV, Afzal A, Baig MA, Kumar AP (2021) Study on effect of ceramics on dry sliding wear behaviour of Al-Cu-Mg based metal matrix composite at different temperature. Mater Today Proc 46:8723–8733

Balraj US, Anitha P (2016) Machinability study on drilling of Al7075/Al2O3P/GRP hybrid metal matrix composites. Ind J Eng 120:422–428

Saravanakumar A, Sasikumar P, Sivasankaran S (2014) Effect of graphite particles in drilling of hybrid aluminum matrix composite. Procedia Eng 97:495–504

Aldaş K, Özkul İ, Hayajneh MT (2016) Effects of machining parameters and reinforcement content on thrust force during drilling of hybrid composites. Mater Test 58(3):280–284

Laghari RA, Li J, Wu Y (2020) Study of machining process of SiCp/Al particle reinforced metal matrix composite using finite element analysis and experimental verification. Materials 13(23):5524

Tosun G, Muratoglu M (2004) The drilling of an Al/SiCp metal-matrix composites Part I: microstructure. Compos Sci Technol 64(2):299–308

Kumar KP, Kishore P, Laxminarayana P (2013) Prediction of thrust force and torque in drilling on aluminum 6061–T6 alloy. Int J Eng Res Technol 2(3):1–6

Çalışkan H, Kurbanoğlu C, Panjan P, Kramar D (2013) Investigation of the performance of carbide cutting tools with hard coatings in hard milling based on the response surface methodology. Int J Adv Manuf Technol 66(5–8):883–893

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Sharath, B.N., Karthik, S., Pradeep, D.G., Madhu, K.S., Venkatesh, C.V. (2023). Machinability Studies on Boron Carbide and Graphite Reinforced Al7029-Based Hybrid Composites. In: Natarajan, E., Vinodh, S., Rajkumar, V. (eds) Materials, Design and Manufacturing for Sustainable Environment. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-3053-9_38

Download citation

DOI: https://doi.org/10.1007/978-981-19-3053-9_38

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-3052-2

Online ISBN: 978-981-19-3053-9

eBook Packages: EngineeringEngineering (R0)