Abstract

In order to further reveal the pile-soil interaction mechanism during precast pile driving in saturated soft soil in coastal areas, the compaction effect and excess pore pressure response of a single pile and adjacent pile penetration under hammer driven pile construction are analyzed by using the cavity expansion and model test method. The results show that pile driving in saturated soil layer will cause large soil compaction and accumulation of excess pore water pressure. Under the model test conditions, the variation range of soil pressure and excess pore pressure is about 0.7–3.0 times and 0.5–1.5 times of soil mass weight stress. As the driving of adjacent pile, soil pressure at the constructed pile-soil interface increases gradually and fluctuates at the same time, and multi peak phenomenon appears under the influence of different soil layers. At the initial stage of driving, the pile driving force is mainly borne by the pile side friction, and the pile tip resistance will actions as the increase of penetration depth, and the relationship between them is basically linear. These results have certain guiding and reference value for the construction of precast pile driving in saturated soft soil in coastal areas.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Due to the special geological causes and forming environment, there are a large number of muddy soft soil and silt foundations in coastal areas, which have low bearing capacity, large deformation or liquefaction characteristics [1, 2]. In practice, it is often necessary to adopt the form of pile foundation to meet the bearing requirements of the superstructure. Precast pile is a common pile type in China’s coastal areas because of its low cost per unit of bearing capacity and relatively suitable geological conditions in coastal areas. However, no matter how to construct precast piles by hammer sinking, vibration sinking or static pressing, it will inevitably disturb the soil around the piles, and there will be obvious soil squeezing effect and excess pore water pressure accumulation in the soil, etc. It is not uncommon for pile foundation construction quality problems to be caused by insufficient understanding of pile-soil interaction mechanism during pile sinking [3,4,5]. In this regard, scholars and engineers at home and abroad have carried out a lot of research work from theoretical analysis, experimental research and field measurement [6,7,8]. In the aspect of theoretical research, Liu et al. [8] derived an analytical solution to the problem of pore expansion of saturated soil in K0 consolidation state, and the anisotropy induced by natural soil consolidation had a great influence on the soil stress and excess pore water pressure around the pile after pore expansion. Mo et al. [9] derived the analytical solution of pore expansion under completely undrained condition, and analyzed the displacement-controlled pile driving process in clay. Zhou et al. [10] used the unified strength theory to study the pore expansion in unsaturated soil under different drainage conditions. Zheng et al. [11] adopted the critical constitutive model of sand considering the characteristics of particle breakage and dilatancy, and established a semi-analytical solution to the problem of pore expansion in sand. It can be seen that in order to better reflect the mechanical properties and actual engineering conditions of various soils, scholars have used the ideal elastic-plastic constitutive model to the more complex critical state model to analyze the problem of column hole expansion considering actual complicated situations such as drainage, particle breakage and stress path. In terms of experimental and measured research, Xu et al. [7] analyzed the development law of pore water pressure and lateral deformation of soil under the action of ground motion through shaking table test of liquefaction site-pile group foundation interaction. Wang et al. [12] carried out the field test of pile sinking of anti-liquefaction drainage rigid pile and ordinary rigid pile. Su et al. [13] established numerical simulation of shaking table of pile group in liquefied lateral expansion site by means of OpenSees numerical method, and the interaction between pile group, pile cap and soil has great influence on lateral deformation of the system. Zhou et al. [14] carried out the model test of transparent soil driven by rectangular piles, and derived the modified reaming theory of rectangular pile section according to the test results. Wang et al. [15] analyzed the variation law of soil pressure and excess pore water pressure of open pile and closed pile in saturated clay during static pressure through laboratory tests. Many scholars used shaking table, centrifuge and numerical simulation methods to carry out the simulation test and field measurement research of pile driving process at different scales. Combined with transparent soil and sensing test technology, the development and distribution law of soil deformation, earth pressure and excess pore water pressure around pile driving process were analyzed.

At present, with the development and utilization of marine wind power resources in the eastern coastal areas of Jiangsu Province, the number and scale of pile foundation construction in coastal soft and liquefiable soil layers are constantly expanding, but the construction quality control still faces many problems. In this paper, based on the construction of precast pile driving in Jiangsu coastal stratum, theoretical analysis of pile driving and soil squeezing effect and indoor model test research are carried out, and the interaction mechanism between pile and soil, the response law of soil pressure and excess pore water pressure in the process of precast pile driving are discussed. The results can provide support for improving pile driving efficiency and construction quality control of precast pile driving in coastal soil stratum.

2 Theoretical Analysis of Pile Squeezing Effect

2.1 Cavity Expansion Theory

The pore expansion theory is a theory to study the changes of stress, pore water pressure and displacement caused by the expansion of cylindrical or spherical holes. In this paper, the analytical solution of undrained pore expansion derived by Mo et al. [9] is used to analyze the pile driving process.

Referring to Fig. 1, the equilibrium equation expression of pore expansion is:

And satisfy two boundary conditions:

Among them, \({\sigma }_{r}\) and \({\sigma }_{\theta }\) are the radial and circumferential stresses in the soil, \(r\) is the distance from the calculation point to the center of the hole, m is the hole shape coefficient, m = 1 is the cylindrical hole, m = 2 is the spherical hole, a and b are the inner diameter and outer diameter of the hole after the expansion of the soil, p is the inner wall pore pressure of the expanded soil and \({p}_{0}\) is the outer wall pore pressure of the soil. In this paper, it is assumed that the soil is an infinite medium, that is, b = ∞. In order to consider the large deformation of soil caused by pore expansion, it is necessary to use the large strain analysis method to derive the analytical solution, and the logarithmic strain expression is as follows:

Among them, \({\varepsilon }_{r}\) and \({\varepsilon }_{\theta }\) are the radial and circumferential strains in the soil, respectively, and \({r}_{0}\) is the initial distance from the calculation point to the center of the hole. In this paper, the stress and strain are positive in compression. For the actual pile driving process, an approximate analysis is made by a series of spherical small hole expansions moving down the pile body, and the soil at the pile bottom is controlled by the small hole expansions at the pile end. The process of hole expansion is assumed to be an initial hole (about 0.1 mm in diameter) that is expanded to the pile diameter (that is, r = D/2, D is the equivalent diameter of precast pile), so as to simulate the soil squeezing effect of precast pile driving.

The unified sand-clay constitutive model CASM is adopted to analyze the constitutive model of soil, which can better simulate the stress-strain characteristics of sand and clay under different loading paths and drainage conditions [16, 17]. The yield surface equation expression of CASM model is:

Where \(\eta \) is the effective stress ratio \(=q/{p}^{^{\prime}}\), q is deviatoric stress, p′ is the effective average stress, and \({p}_{y}^{^{\prime}}\) is the pre-consolidation pressure; \(n\) is the stress state coefficient and \({r}^{*}\) is the spacing ratio, both of which belong to the newly introduced material parameters of CASM. The model uses an unrelated flow criterion to control the plastic strain of materials, and the expression is:

In which \({\dot{\delta }}^{p}\) is the plastic volumetric strain rate, \(\delta ={\varepsilon }_{r}+m{\varepsilon }_{\theta }\); \({\dot{\gamma }}^{p}\) is the plastic shear strain rate, \(\gamma ={\varepsilon }_{r}-{\varepsilon }_{\theta }\); \(M\) is the slope of the critical state line in \({p}^{^{\prime}}-q\) space.

The specific values of soil parameters are shown in Table 1, and the saturation degree \({\gamma }_{sat}\) of soil is 18 kN/m3. The friction angle \({\delta }_{f}\) of pile-soil interface is \(\phi /2\), where \(\phi \) is the internal friction angle of soil, which is calculated by \(M=\frac{6\mathrm{sin}\phi }{3-\mathrm{sin}\phi }\). The maximum penetration depth of pile foundation is 1 m.

2.2 Calculation Method of Pile Sinking Resistance

The pile driving force Q when the penetration depth z is controlled according to the displacement consists of the pile end force \({Q}_{tip}\) and the pile side force \({Q}_{shaft}\), and the calculation formulas are as follows:

Among them: \({q}_{t}\) is the pile end resistance, and \({q}_{s,z}\) is the pile side resistance at depth z. The specific expression is:

Among them: \({\sigma }_{r}^{\mathrm{^{\prime}}}\) is the effective radial stress at the pile tip (depth z) caused by pile sinking, and \(\Delta u\) is the excess pore water pressure at the pile tip caused by pile sinking; \({\sigma }_{r,\mathrm{z}}^{\mathrm{^{\prime}}}\) and \(\Delta u{}_{Z}\) are the effective radial stress and excess pore water pressure at the pile side at the depth z, respectively, which can be calculated by the expansion of spherical holes at the corresponding depth.

2.3 Calculation Result Analysis

Soil squeezing effect will occur in the process of pile sinking, which will cause the stress change of the soil around the pile. Figure 2 shows the calculated average stress increment \(\Delta p\) caused by pile driving, where the average stress \(p = \sigma_{r} + 2\sigma_{\theta } /3\). The pile sinking causes the average stress around the pile to increase, and the influence range is within 3 times of the pile diameter around the pile, and the change of soil stress within 3 times of the pile diameter depth on the surface can be neglected. Figure 3 shows the distribution of excess pore water pressure \(\Delta u\) caused by pile driving, and the influence range is similar to the average stress increment, with the value slightly larger by about 20%.

The distribution of effective radial stress and excess pore water pressure at the pile tip along the horizontal direction after the pile is sunk by 1 m is shown in Fig. 4(a). The effective radial stress around the pile is distributed horizontally, which indicates that the soil after soil compaction disturbance is in a critical state, and the negative value indicates that there is excessive excess pore water pressure in this area. With the increase of horizontal distance, the effective radial stress away from the soil first increases and then decreases. It can be seen that the size of plastic zone is about 2.5D, and the overall influence range of pile sinking is about 4D. The excess pore water pressure decreases rapidly with the horizontal distance, and the influence range is less than the effective radial stress, which is about 3D. Figure 4(b) shows the distribution of pile body friction (black line) and excess pore water pressure (red line) along the depth of pile body after pile sinking for 1m, and its linear distribution may be due to the influence of near-surface and too small in-situ stress level.

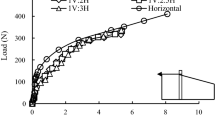

The evolution of the total penetration force \(Q\), tip force \({Q}_{tip}\) and side force \({Q}_{shaft}\) of the displacement pile in the process of pile sinking is shown in Fig. 5(a). When the penetration depth is greater than 0.5 m, the pile driving force is mainly borne by the pile side friction. The variation of pile end resistance \({q}_{t}\) and excess pore water pressure at pile end with penetration depth is shown in Fig. 5(b).

3 Model Test on Pile Sinking Process

3.1 Test Device and Method

As shown in Fig. 6, steel drum model box (inner diameter 1000 mm) is used, and earth pressure box and pore pressure meter are respectively arranged on both sides of concrete model pile body to measure the earth pressure and pore water pressure at the pile-soil interface. The size of the concrete model pile is 60 mm * 60 mm * 1000 mm, and the length-diameter ratio of the concrete model pile is 16.7. The wires of the earth pressure box and pore pressure meter arranged inside the concrete model pile are led out at a distance of 200 mm from the top of the model pile. The concrete model pile is poured with C30 concrete. Due to the size limitation and the need of embedded sensors, the coarse aggregate of poured concrete is screened with a 5 mm screen to better fill the inner space of the model pile mold, and at the same time, the contact between large aggregate and sensors can be avoided to affect the measurement results.

3.2 Soil Sample and Sensor Layout

The soil samples used in the test are silty clay from the construction site of a substation in Yancheng. According to the test requirements, soil samples with 15% and 25% water contents are prepared, sealed and stored for 24 h, and then packed into the model box in layers in turn. The packing density of each layer of soil samples is strictly controlled according to the test design. Density of the top, middle and bottom soil layers are about 1.8, 1.6 and 2.1 g/cm3. Water contents of the top, middle and bottom soil layers are 15, 25 and 25%.

In order to measure the changes of soil pressure and pore water pressure in the soil around the pile caused by pile sinking, sensors are arranged at positions 3 times and 6 times away from the model pile body by using positioning rods. Among them, two positioning rods are respectively fixed with three pore pressure meters, and the other two positioning rods are respectively fixed with three earth pressure boxes, and each sensor is arranged in turn with an upward spacing of 200 mm from the bottom of the positioning rod 300 mm. Sensors of the pile body are upward from the pile bottom 100 mm in turn, with a spacing of 150 mm. See Fig. 7 for specific sensor arrangement.

Considering the effect of hammering into piles, the impact force on precast piles is about \(1\times {10}^{6}\mathrm{ N}\), and the force similarity constant in model test is about \({S}_{F}=0.001\). Therefore, in the test, a weight plate weighing 10 kg is selected, and it is allowed to fall freely along the guide rod by 150 mm, and the simulated impact force is about \(1\times {10}^{3}\mathrm{ N}\), with hammering interval of 2 s. In the process of hammering, laser levels is used to proofread the verticality of the model pile to ensure the effective application of hammering force and the stability of the pile body in the model test.

3.3 Test Results and Analysis

In this model test, the soil squeezing effect of pile sinking and the response of excess pore pressure in soil are analyzed under two working conditions of single pile and adjacent pile penetration. In order to facilitate the post-processing of data, the pile body is marked every 50 mm During the process of pile sinking, the data collector continuously collects data every 20 s. In the later stage, five groups of data from the sinking position to the vicinity of the pile body mark are selected, and the average value is taken.

3.3.1 Analysis of Soil Squeezing Effect

The change of earth pressure of the soil around the pile in the process of pile sinking is shown in Fig. 8, and the data of the change of earth pressure in the figure is normalized by the self-weight stress at the corresponding position. It can be seen that when the pile driving depth is within the range of 400 mm, although there is a certain upward trend in the change of the earth pressure around the pile with 3 times and 6 times the pile diameter, the magnitude is small. The reason is that the consolidation stress level of the shallow soil layer is low, and the deformation limit is small. This phenomenon is basically consistent with the theoretical analysis results of small hole expansion. When the pile depth is in the range of 400–600 mm, the model pile body passes through the relatively soft saturated soil layer in the middle, and the data of earth pressure at 3 times of pile diameter and 6 times of pile diameter are greatly increased, with the largest increase at the depth of about 700 mm, and then there is a downward trend. On the whole, the variation range of earth pressure is 0.7–3.0 times of self-weight stress level. When the pile depth is 600–800 mm, when the model pile enters the fourth layer of soil, there are some differences in the earth pressure changes of 3 times the pile diameter and 6 times the pile diameter, and the law is not obvious. The main reason for the analysis is that the sensor placement position is displaced to the upper side of the sinking depth, while the lateral soil squeezing during the model pile penetration mainly affects the soil within the sinking depth range. The test results also confirm that it is reasonable to assume that the soil around the pile is only affected by the expansion of small holes with the same depth in theoretical analysis.

3.3.2 Response of Excess Pore Pressure in Surrounding Soil

The variation of soil pore pressure around the pile during pile sinking is shown in Fig. 9. Similarly, the pore pressure data are normalized according to the self-weight stress at the corresponding position. At 3 times of pile diameter, with the increase of pile sinking depth, the pore pressure meter data at different depths of soil around the pile all show an obvious upward trend, with the range of 0.5–1.5 times of self-weight stress level. 6 times of pile diameter and different depths, the change of pore pressure count value is obviously less than 3 times of pile diameter, and the maximum increase of excess pore pressure is about 0.5 times of deadweight stress level. When the pile depth is shallow at 150 mm, the response of the excess pore pressure with the embedded depth of 300 mm is the most obvious. With the increase of the embedded depth, the excess pore pressure with the embedded depth of 700 mm increases greatly, and then keeps a high level. The reason may be that the depth of 200–600 mm in the model box is saturated weak soil layer, and the outside of the model box is an undrained boundary, so the pore pressure meter with the embedded depth of 700 mm is more obviously affected by the accumulation of excess pore pressure in saturated soil layer.

4 Conclusion

In this paper, the squeezing effect of precast pile driving in saturated soil and the response of excess pore water pressure in soil are analyzed by theoretical calculation and model test, and the variation law of soil pressure and excess pore water pressure in the pile-soil interface and the soil around the pile during driving is analyzed. The main conclusions are as follows:

-

(1)

Based on the theory of spherical pore expansion, considering the complex stress-strain relationship of soil, the large deformation during pore expansion and the development of plastic zone around pile caused by pile penetration, the evolution law of soil stress, excess pore water pressure and pile penetration resistance in the process of precast pile driving is analyzed.

-

(2)

The phenomenon of soil squeezing and excess pore water pressure accumulation caused by precast pile driving in saturated soil is studied by model test. Under the condition of model test, the increase range of soil pressure is 0.7–3.0 times of deadweight stress level, and the variation range of excess pore water pressure is 0.5–1.5 times of deadweight stress level. When adjacent piles are sunk, the earth pressure at the pile-soil interface shows a fluctuating upward trend, and multi-peak phenomenon occurs when affected by different soil properties, and the earth pressure increases by 1.0–3.0 times of the self-weight stress level.

-

(3)

The model test results are in good agreement with the theoretical analysis in the variation law of soil stress and excess pore water pressure, but the model test data fluctuates obviously, mainly due to the influence of the filling of test soil samples and the response of sensors. In the later stage, necessary field measurement work will be carried out to enhance the understanding and grasp of pile-soil interaction mechanism in the process of deep pile, and provide more valuable guidance for actual construction.

References

Lin, Z.Q.: Mechanism of rigid pile composite foundation influenced by marine soft soil. Geotech. Eng. Tech. 33(6), 328–333, 371 (2019)

Lv, G.R., Ge, J.D., Xiao, H.T.: Treatment of coastal soft foundation with cement-soil mixing pile. J. Shandong Univ. (Eng. Sci.) 50(3), 73–81 (2020)

Li, S.Y., Liang, S., Wang, B., et al.: Research and application of prestressed pipe pile construction quality control under ultra-deep soft soil foundation. Constr. Technol. 46(1), 18–24 (2017)

Zhong, J.M.: Quality problem and treatment of pile foundation caused by extrusion of precast pile. Build. Struct. 47(s2), 458–463 (2017)

Zhang, Z.Z., Gui, Z.P., Zhang, R.J.: Horizontal additional response analysis of adjacent existing loaded pile foundation caused by embankment filling on deep soft soil. J. China Foreign Highway 38(6), 7–13 (2018)

Fu, Y., Huang, F.Y., Chen, B.C., et al.: Shaking table test on structure-soil-pile of PHC in coastal soft soil area. China J. Highw. Transp. 30(10), 81–92 (2017)

Xu, C.S., Dou, P.F., Du, X.L., et al.: Dynamic response analysis of liquefied site-pile group foundation-structure system—large-scale shaking table model test. Chin. J. Geotech. Eng. 41(12), 2173–2181 (2019)

Liu, S.P., Shi, J.Y., Lei, G.H., et al.: Elastoplastic analysis of cylindrical cavity expansion in K0 consolidated saturated soil. Rock Soil Mech. 34(2), 389–403 (2013)

Mo, P.Q., Yu, H.S.: Undrained cavity expansion analysis with a unified state parameter model for clay and sand. Geotechnique 67(6), 503–515 (2017)

Zhou, F.X., Mou, Z.L., Yang, R.X., et al.: Analytical analysis on the expansion of cylindrical in unsaturated soils under different drainage conditions. Chin. J. Theor. Appl. Mech. 53(5), 1496–1509 (2021)

Zheng, J.H., Qi, C.G., Wang, X.Q., et al.: Elasto-plastic analysis of cylindrical cavity expansion considering particle breakage of sand. Chin. J. Geotech. Eng. 41(11), 186–194 (2019)

Wang, X.Y., Liu, H.L., Jiang, Q., et al.: Field tests on response of excess pore water pressures of liquefaction resistant rigid-drainage pile. Chin. J. Geotech. Eng. 39(4), 645–651 (2017)

Su, L., Tang, L., Ling, X.C., et al.: Numerical simulation of shake-table experiment on dynamic response of pile foundation in liquefaction-induced lateral spreading ground. J. Disaster Prev. Mitig. Eng. 39(2), 227–235 (2019)

Zhou, H., Yuan, J.R., Liu, H.L., et al.: Model test of rectangular pile penetration effect in transparent soil. Rock Soil Mech. 40(11), 307–316 (2019)

Wang, Y.H., Zhang, M.Y., Liu, X.Y., et al.: Laboratory test comparative study on open-close piles during jacked pile-jacking based on pile-soil interface stress measurement. J. Central South Univ. (Sci. Technol.) 52(2), 599–606 (2021)

Yu, H.S.: CASM: A unified state parameter model for clay and sand. Int. J. Numer. Anal. Meth. Geomech. 22(8), 621–653 (1998)

Mo, P.Q., Gao, X.W., Huang, Z.F., et al.: Analytical method for settlement control of displacement pile induced by undercrossing tunnel excavation. Rock Soil Mech. 40(10), 121–130, 141 (2019)

Acknowledgments

This research was supported by the National Science Foundation of China (Grant No. 51408595), the Scientific Research Fund of Institute of Engineering Mechanics, China Earthquake Administration (Grant No. 2020D16) and the 2020 Science and Technology Project of State Grid Jiangsu Electric Power Engineering Consulting Co., Ltd. (Grant No. J202006). These supports are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2022 The Author(s)

About this paper

Cite this paper

Xie, H., Han, C., Du, C., Wang, B., Zhang, Y., Mo, P. (2022). Analysis of Pile-Soil Interaction of Precast Pile Driven in Coastal Strata. In: Feng, G. (eds) Proceedings of the 8th International Conference on Civil Engineering. ICCE 2021. Lecture Notes in Civil Engineering, vol 213. Springer, Singapore. https://doi.org/10.1007/978-981-19-1260-3_43

Download citation

DOI: https://doi.org/10.1007/978-981-19-1260-3_43

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1259-7

Online ISBN: 978-981-19-1260-3

eBook Packages: EngineeringEngineering (R0)