Abstract

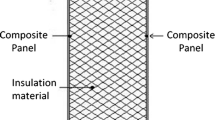

In order to improve the energy efficiency of buildings, there is a need to develop and utilize composites with good thermal, mechanical and durability properties in the construction of buildings. Comprehensive development and evaluation of energy-efficient fibre-reinforced composites for the construction of building walls are being undertaken at the University of Windsor. This paper presents some preliminary results on the influence of various recycled aggregates on the compressive strength, thermal conductivity, water sorption and ultrasonic pulse velocity (UPV) of the developed composites. In this study, a high volume of Portland cement was replaced with fly ash, and recycled concrete, recycled asphalt, recycled glass, and recycled rubber were used as a total replacement of the natural aggregates. The results of this study showed that the sustainability and thermal properties of fibre-reinforced composites can be improved with the utilization of recycled aggregates. However, there could be a slight detrimental impact on the compressive strength of the composites due to their lower stiffness/high water absorption. Nonetheless, fibre-reinforced composites with good mechanical and durability properties can be produced with recycled aggregates and used for the construction of walls in buildings in order to improve the energy efficiency of buildings.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Andrew RM (2018) Global CO2 emissions from cement production. Earth Syst Sci Data 10:195–217. https://doi.org/10.5194/essd-10-195-2018

Asadollahfardi G, Delnavaz M, Rashnoiee V, Fazeli A, Gonabadi N (2016) Dataset of producing and curing concrete using domestic treated wastewater. Data Br 6:316–325. https://doi.org/10.1016/j.dib.2015.12.020

Asasutjarit C, Hirunlabh J, Khedari J, Charoenvai S, Zeghmati B, Shin UC (2007) Development of coconut coir-based lightweight cement board. Constr Build Mater 21:277–288. https://doi.org/10.1016/j.conbuildmat.2005.08.028

ASTM (2014) ASTM Standard C1757—Standard test method for determination of one-point, bulk water sorption of dried concrete. ASTM Int I, pp 14–16. https://doi.org/10.1520/C1757-13

ASTM C597 (2016) Standard test method for pulse velocity through concrete. American Society Testing Matererials, West Conshohocken, PA, USA, pp 1–4. https://doi.org/10.1520/C0597-16.2

ASTM International (2005) C109/C109M-05. Standard test method for compressive strength of hydraulic cement mortars. Annual B. ASTM Standard, p 9. https://doi.org/10.1520/C0109

Booya E, Gorospe K, Ghaednia H, Das S (2019) Durability properties of engineered pulp fibre reinforced concretes made with and without supplementary cementitious materials. Compos Part B Eng 172:376–386. https://doi.org/10.1016/j.compositesb.2019.05.070

Bouzoubaâ N, Zhang MH, Malhotra VM (2001) Mechanical properties and durability of concrete made with high-volume fly ash blended cements using a coarse fly ash. Cem Concr Res 31:1393–1402. https://doi.org/10.1016/S0008-8846(01)00592-0

Chen M, Zhong H, Chen L, Zhang Y, Zhang M (2021) Engineering properties and sustainability assessment of recycled fibre reinforced rubberised cementitious composite. J Clean Prod 278. https://doi.org/10.1016/j.jclepro.2020.123996

de Brito J, Kurda R (2020) The past and future of sustainable concrete: A critical review and new strategies on cement-based materials. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.123558

Filho RDT, Sanjuán MA (1999) Effect of low modulus sisal and polypropylene fibre on the free and restrained shrinkage of mortars at early age. Cem Concr Res 29:1597–1604. https://doi.org/10.1016/S0008-8846(99)00136-2

Flores-Alés V, Alducin-Ochoa JM, Martín-del-Río JJ, Torres-González M, Jiménez-Bayarri V (2020) Physical-mechanical behaviour and transformations at high temperature in a cement mortar with waste glass as aggregate. J Build Eng 29. https://doi.org/10.1016/j.jobe.2019.101158

Gartner E, Hirao H (2015) A review of alternative approaches to the reduction of CO2 emissions associated with the manufacture of the binder phase in concrete. Cem Concr Res 78:126–142. https://doi.org/10.1016/j.cemconres.2015.04.012

Handoo SK, Agarwal S, Agarwal SK (2002) Physicochemical, mineralogical, and morphological characteristics of concrete exposed to elevated temperatures. Cem Concr Res 32:1009–1018. https://doi.org/10.1016/S0008-8846(01)00736-0

Herrero S, Mayor P, Hernández-Olivares F (2013) Influence of proportion and particle size gradation of rubber from end-of-life tires on mechanical, thermal and acoustic properties of plaster-rubber mortars. Mater Des 47:633–642. https://doi.org/10.1016/j.matdes.2012.12.063

Huang B, Shu X, Burdette EG (2006) Mechanical properties of concrete containing recycled asphalt pavements. Mag Concr Res 58:313–320. https://doi.org/10.1680/macr.2006.58.5.313

Ibrahim A, Mahmoud E, Khodair Y, Patibandla VC (2014) Fresh, mechanical, and durability characteristics of self-consolidating concrete incorporating recycled asphalt pavements. J Mater Civ Eng 26:668–675. https://doi.org/10.1061/(asce)mt.1943-5533.0000832

Jiang H, Han J, Li Y, Yilmaz E, Sun Q, Liu J (2020) Relationship between ultrasonic pulse velocity and uniaxial compressive strength for cemented paste backfill with alkali-activated slag. Nondestruct Test Eval 35:359–377. https://doi.org/10.1080/10589759.2019.1679140

Joshaghani A, Moeini MA, Balapour M, Moazenian A (2018) Effects of supplementary cementitious materials on mechanical and durability properties of high-performance non-shrinking grout (HPNSG). J Sustain Cem Mater. https://doi.org/10.1080/21650373.2017.1372318

Katzer J, Domski J (2012) Quality and mechanical properties of engineered steel fibres used as reinforcement for concrete. Constr Build Mater 34:243–248. https://doi.org/10.1016/j.conbuildmat.2012.02.058

Kazemian F, Rooholamini H, Hassani A (2019) Mechanical and fracture properties of concrete containing treated and untreated recycled concrete aggregates. Constr Build Mater 209:690–700. https://doi.org/10.1016/j.conbuildmat.2019.03.179

Kulasuriya C, Vimonsatit V, Dias WPS (2020) Performance based energy, ecological and financial costs of a sustainable alternative cement. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.125035

Mardani-Aghabaglou A, Tuyan M, Ramyar K (2015) Mechanical and durability performance of concrete incorporating fine recycled concrete and glass aggregates. Mater Struct Constr 48:2629–2640. https://doi.org/10.1617/s11527-014-0342-3

Meyer C (2009) The greening of the concrete industry. Cem Concr Compos 31:601–605. https://doi.org/10.1016/j.cemconcomp.2008.12.010

Nedeljković M, Luković M, van Breugel K, Hordijk D, Ye G (2018) Development and application of an environmentally friendly ductile alkali-activated composite. J Clean Prod 180:524–538. https://doi.org/10.1016/j.jclepro.2018.01.162

Parghi A, Shahria Alam M (2016) Physical and mechanical properties of cementitious composites containing recycled glass powder (RGP) and styrene butadiene rubber (SBR). Constr Build Mater 104:34–43. https://doi.org/10.1016/j.conbuildmat.2015.12.006

Purnell P (2013) The carbon footprint of reinforced concrete. Adv Cem Res 25:362–368. https://doi.org/10.1680/adcr.13.00013

Roychand R, Gravina RJ, Zhuge Y, Ma X, Youssf O, Mills JE (2020) A comprehensive review on the mechanical properties of waste tire rubber concrete. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2019.117651

Sasanipour H, Aslani F (2020) Durability properties evaluation of self-compacting concrete prepared with waste fine and coarse recycled concrete aggregates. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2019.117540

Schumacher K, Saßmannshausen N, Pritzel C, Trettin R (2020) Lightweight aggregate concrete with an open structure and a porous matrix with an improved ratio of compressive strength to dry density. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2020.120167

Siddique R (2004) Performance characteristics of high-volume Class F fly ash concrete. Cem Concr Res 34:487–493. https://doi.org/10.1016/j.cemconres.2003.09.002

Somna R, Jaturapitakkul C, Amde AM (2012) Effect of ground fly ash and ground bagasse ash on the durability of recycled aggregate concrete. Cem Concr Compos 34:848–854. https://doi.org/10.1016/j.cemconcomp.2012.03.003

Spiesz P, Yu QL, Brouwers HJH (2013) Development of cement-based lightweight composites - Part 2: Durability-related properties. Cem Concr Compos. https://doi.org/10.1016/j.cemconcomp.2013.03.029

Thomas BS, Gupta RC, Mehra P, Kumar S (2015) Performance of high strength rubberized concrete in aggressive environment. Constr Build Mater 83:320–326. https://doi.org/10.1016/j.conbuildmat.2015.03.012

Wang W, Lu C, Li Y, Li Q (2017) An investigation on thermal conductivity of fly ash concrete after elevated temperature exposure. Constr Build Mater. https://doi.org/10.1016/j.conbuildmat.2017.05.068

Wang X, Xia J, Nanayakkara O, Li Y (2017) Properties of high-performance cementitious composites containing recycled rubber crumb. Constr Build Mater 156:1127–1136. https://doi.org/10.1016/j.conbuildmat.2017.09.024

Yang EH, Yang Y, Li VC (2007) Use of high volumes of fly ash to improve ECC mechanical properties and material greenness. ACI Mater J 104:620–628. https://doi.org/10.14359/18966

Yang J, Du Q, Bao Y (2011) Concrete with recycled concrete aggregate and crushed clay bricks. Constr Build Mater 25:1935–1945. https://doi.org/10.1016/j.conbuildmat.2010.11.063

Zhou H, Brooks AL (2019) Thermal and mechanical properties of structural lightweight concrete containing lightweight aggregates and fly-ash cenospheres. Constr Build Mater 198:512–526. https://doi.org/10.1016/j.conbuildmat.2018.11.074

Zou F, Hu C, Wang F, Ruan Y, Hu S (2020) Enhancement of early-age strength of the high content fly ash blended cement paste by sodium sulfate and C–S–H seeds towards a greener binder. J Clean Prod 244. https://doi.org/10.1016/j.jclepro.2019.118566

Acknowledgements

The authors acknowledge the Natural Sciences and Engineering Research Council of Canada for the financial support provided.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 Canadian Society for Civil Engineering

About this paper

Cite this paper

Adesina, A., Das, S. (2023). Influence of Various Recycled Aggregates on the Compressive Strength, Thermal Conductivity, Water Sorption and UPV of Fibre-Reinforced Composites. In: Walbridge, S., et al. Proceedings of the Canadian Society of Civil Engineering Annual Conference 2021 . CSCE 2021. Lecture Notes in Civil Engineering, vol 248. Springer, Singapore. https://doi.org/10.1007/978-981-19-1004-3_15

Download citation

DOI: https://doi.org/10.1007/978-981-19-1004-3_15

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1003-6

Online ISBN: 978-981-19-1004-3

eBook Packages: EngineeringEngineering (R0)